Freeze-dried food is a global hit these days. It fits into a healthy lifestyle, has a long shelf life, has a nice taste, and has almost the same nutritional content. The process is relatively simple – you freeze the food and place it in a vacuum – and the water from the food goes straight from ice to steam. The process is called lyophilization, and we’ll show you how professional freeze-drying machines are made – and how Original Prusa and Trilab 3D printers help in the process.

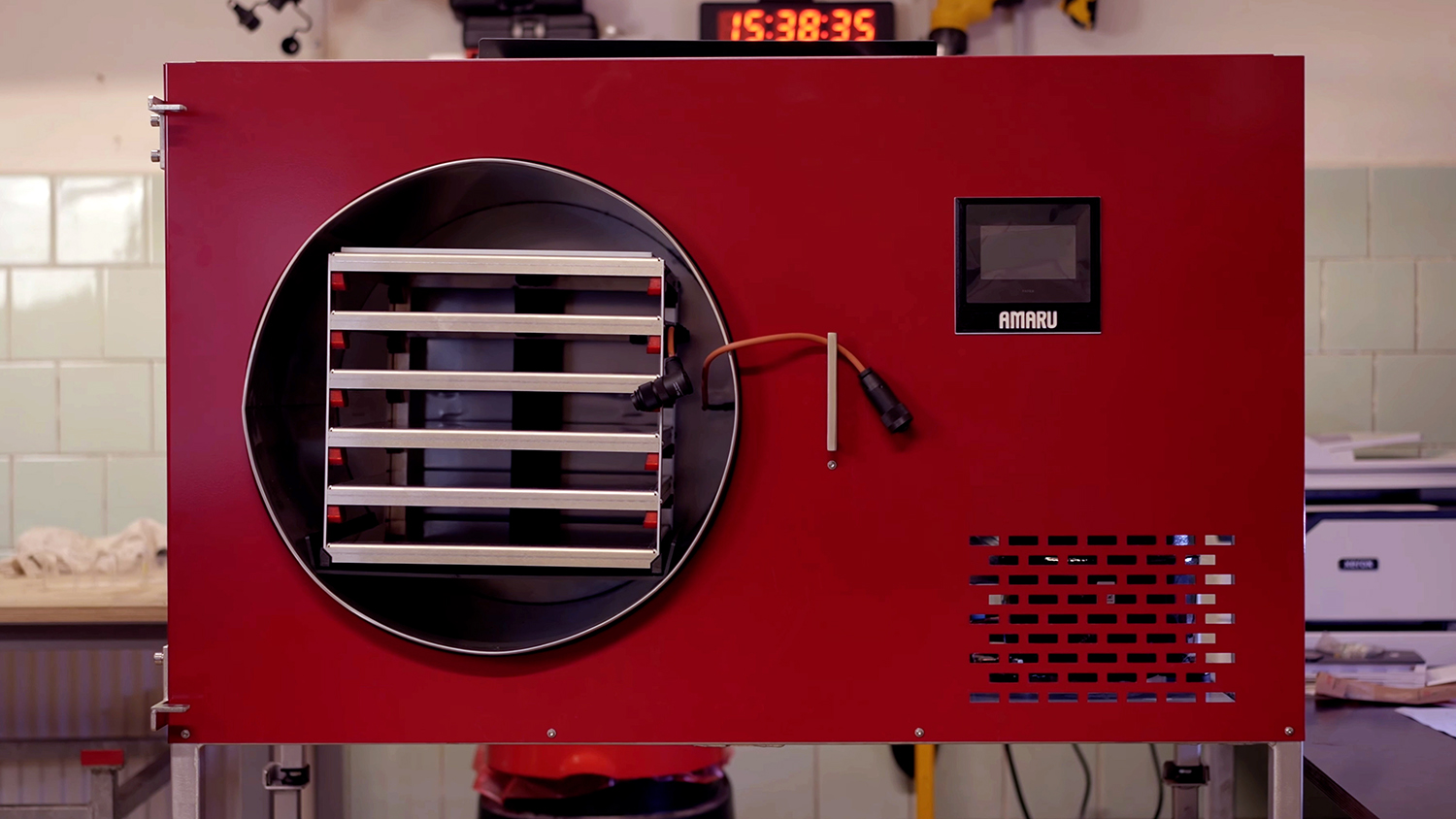

Meet the Czech company Lyotrade, which builds the increasingly popular AMARU lyophilizer. The name is a nod to history: The technique of freeze-drying food dates back to the Inca Empire and Túpac Amaru was the last Incan emperor. As far as we know, Incans used the freezing heights of the Andes to dry their food. Today, things are simpler.

At first glance, AMARU looks like a big oven of sorts, with a sizable, clear window showing the inside full of steel shelves. But a closer look reveals a complex machine with fans, motors, filters, and electronics. When you open the side door, you’ll find a whole bunch of 3D printed parts!

Prints from advanced materials

“10-15% of the AMARU’s parts are 3D printed,” says Karel Schmiedberger, Lyotrade’s CEO. The company’s workshop is not far from Prague and we got to see not only a lot of finished AMARUs but also the whole production line. The space is equipped with an array of industry-standard tools and you can see a lot of printed parts.

“We use 3D printing for both prototyping and production,” says Karel Schmiedberger, showing us a test model of a fan connector as an example. Smaller printed components are stored in wall drawers – right next to screws and nuts, all carefully labeled and ready for use.

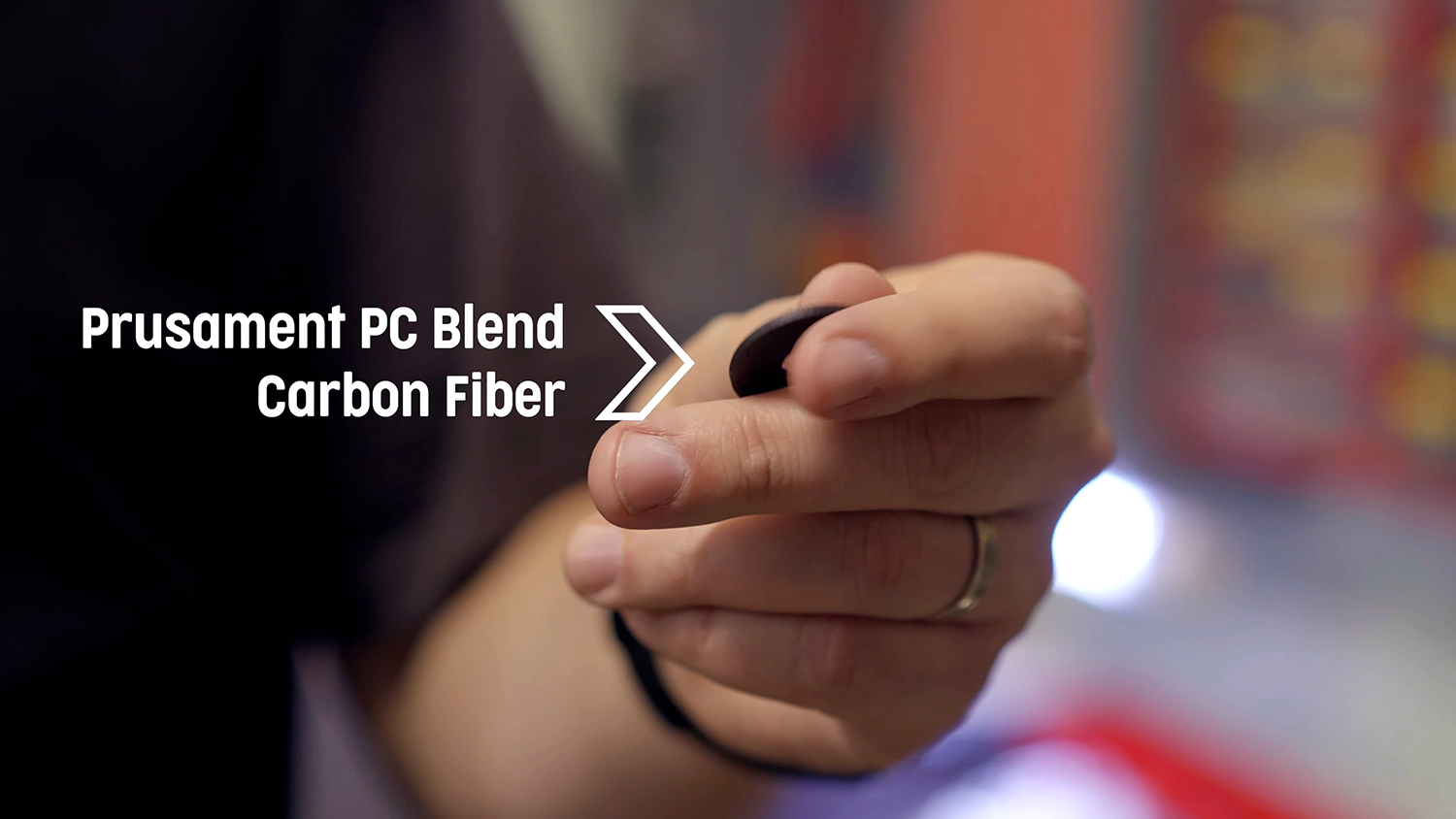

Printed components are made mostly out of advanced materials such as polyester (CPE), ABS, PC or fluorodur (PVDF).

“We need to ensure these parts can withstand conditions as harsh as 100°C,” Karel Schmiedberger says about the choice of materials that need to be not only mechanically durable but also resist oils, ozone, and other chemicals.

Using Original Prusa and Trilab

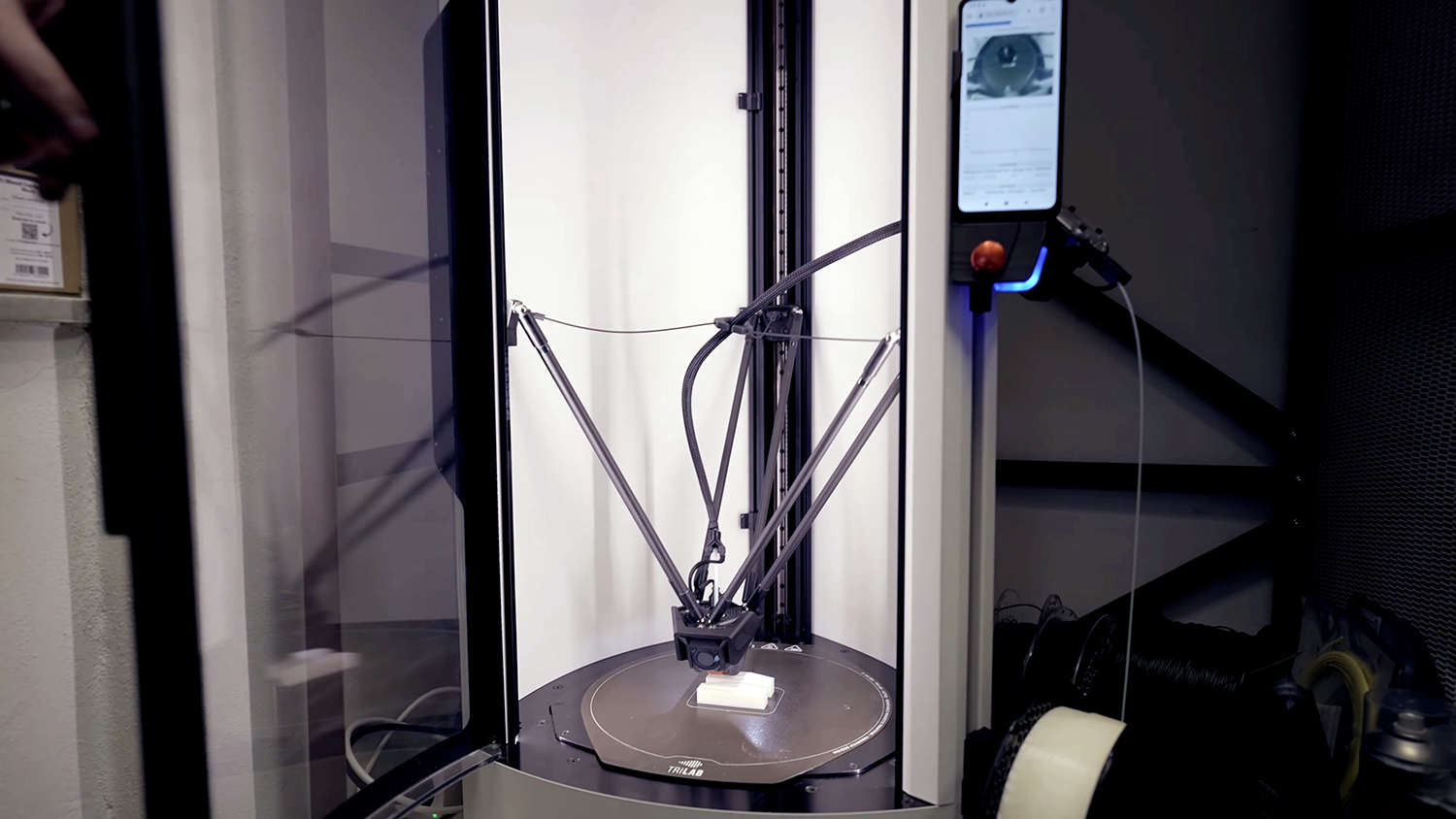

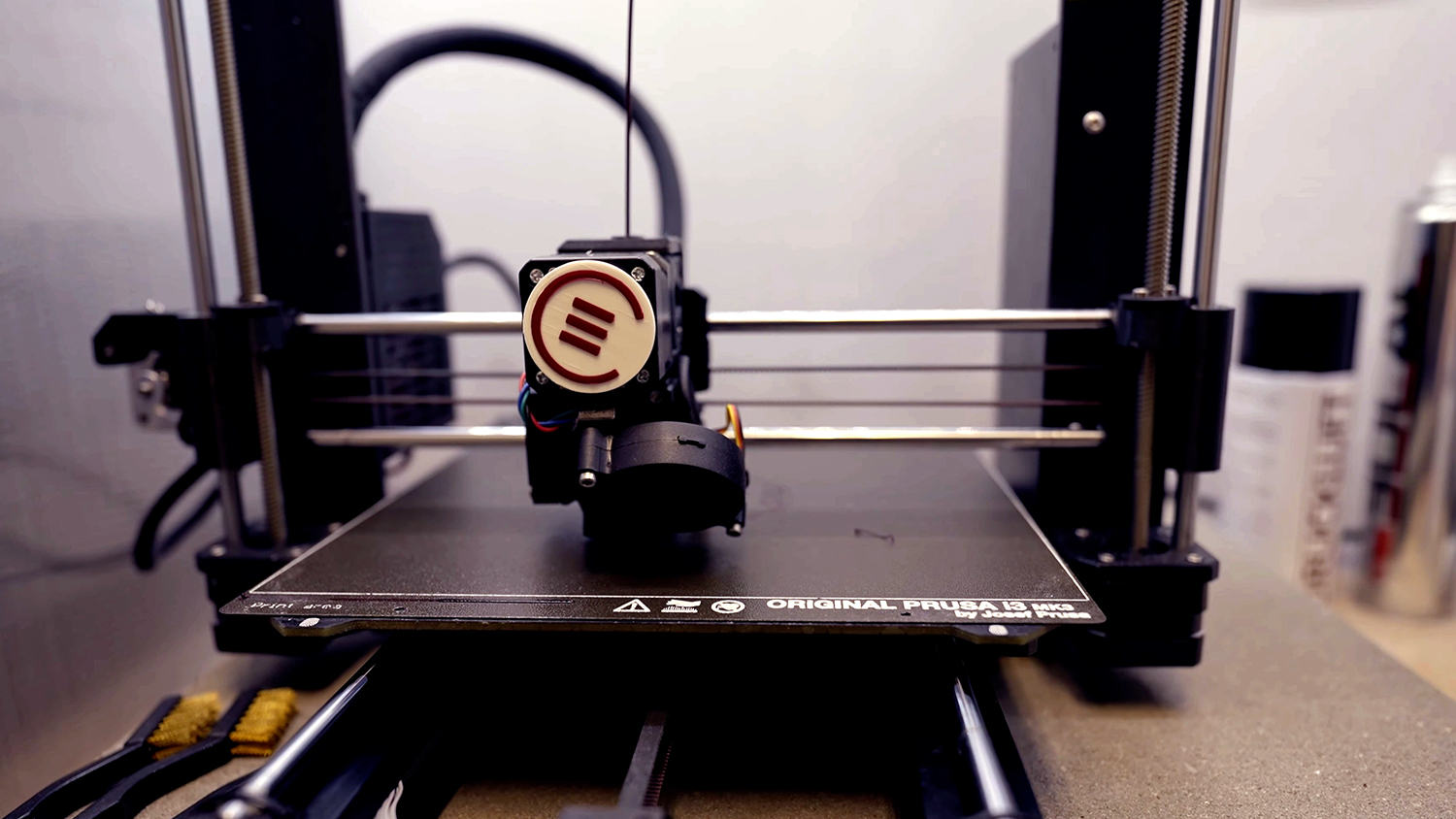

For this, they use Original Prusa MK3S+ and Trilab Azteq Industrial printers. The first is more than four years old and has been upgraded from the original model to the latest version – and provides a great service whatever the task! With the Trilab Azteq, however, Lyotrade has significantly expanded its production capabilities: They can produce larger, high-quality prints and, with the heated chamber, even print those with abovementioned advanced materials.

The idea of using 3D printing for production is similar to the one with which Karel Schmiedberger and his business partner started the company: “If we can’t obtain them, we’ll start making them!” Karel Schmiedberger smiles.

He and his partner had more than 15 years of experience selling laboratory drying equipment. Then one day they went looking for a lyophilizer manufacturer – but no one could meet their needs. So Lyotrade and their successful business was born. Today, AMARU is a popular brand among small and medium business companies producing freeze-dried food.

Freedom and flexible production

Using Original Prusa and Trilab 3D printers has given them a high degree of control over their prototyping and production process. 3D printing allows them to respond quickly to design changes and new requirements.

“We control our prototyping and production, changing both parts and production volumes when we need to,” explains Karel Schmiedberger.

When asked about the future, he’s enthusiastic:

“We plan to use more advanced materials to replace some of the traditional metal and mass-produced parts. We’re excited to see how 3D printing evolves to further simplify and revolutionize the manufacturing process,” Schmiedberger says.

Thanks for the article! I enjoyed playing papa’s burgeria io. The graphics and animations are colorful and cute.

google

delete my account please thank you