It’s been more than three months since we revealed the upcoming Original Prusa XL, so it’s time to give you an update on the development and also answer at least some of the most frequently asked questions.

I know these are not the best times to share a dev diary – a war is raging in Ukraine, just several hundred kilometers from our factory, and there are more pressing issues than discussing the features of a 3D printer. We’re trying to help wherever we can and once again I’m amazed by the generosity and support coming from all around. But also we don’t want to keep you in the dark regarding your pre-orders. So, here’s an overview of the current stage of development with more news coming in a couple of weeks, hopefully in better times.

Please understand that we can’t fully disclose everything yet, so if the thing you’re most interested in is not explained here today, it’s likely because that feature is still under development. However, rest assured, that once we’re certain about the exact numbers and specifications, we’ll share them with you in future Dev Diaries.

What’s been happening?

I already covered one major obstacle extensively in the 2021 Recap article, so just in short – the worldwide shortage of various components and materials is affecting our production and development, and the XL is no exception. However, there’s a silver lining to that. The unavailability of the main processor for the XL’s motherboard caused us to look for alternatives. Eventually, we settled on a newer generation of the same chip, which brings a bit more horsepower and allows us to do some extra things with the firmware – like embedding certain information about the machine into the OTP memory, e.g. hardware revision of the board and installed accessories, etc. which will make things like firmware updates more convenient. On the other hand, we’ve lost some time on reworking the firmware to make it compatible with the new CPU…

I also teased that we’re starting our own SMT production line so we can be more independent. The XL features several electronic boards and all of them have been manufactured on our SMT line – this is hugely convenient, especially in these times with uncertain delivery dates and issues with transportation. So while this may not sound very exciting to you, it’s an incredibly important step forward for us.

However, let’s skip to something more visible and practical!

Eliminating the wipe tower

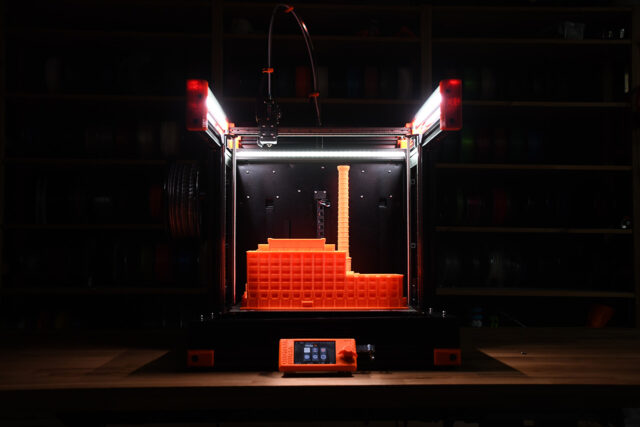

One of the most frequent questions we received was whether the XL will need a wipe tower for multi-material printing. I’m happy to say that we’re on the right track to eliminate the wipe tower in a majority of cases and we have already completed several large multi-material prints that required no wipe towers at all.

To achieve this, we’ve combined the hardware-based advantages of the new extruder with advanced software tweaks (not just wipe to infill) to minimize the amount of filament that flows out of the nozzle during filament changes. Basically, we want to avoid a solution that would require dropping any sort of debris from the nozzle into, e.g., some sort of a container located inside the printer. You would have to constantly think about emptying the “waste bin” – and if you’d forget to empty it, then the debris would start piling up inside the printer. Also, with massive multi-material prints which can go even over 10.000 material changes, there would be a ton of debris constantly.

So we had to figure out a different approach. With the Nextruder on board the XL, we can control retractions and nozzle cooling much more effectively, which gives us the opportunity to eliminate the wipe tower and also prevent the nozzle from dropping bits of plastic into the machine. This way, you’ll save considerable amounts of material, which is useful when, e.g., printing with soluble materials which are generally more expensive.

What’s next?

Right now, we’re focusing on finalizing the Nextruder design and optimizing the printing performance so we can finally share some numbers with you soon. Apart from the Nextruder, the majority of the XL’s hardware is pretty close to the final stage, so we’re currently building a larger number of internal testing units to share with our colleagues in the company who will start testing the new machines.

Of course, the firmware development is also in full swing. Right now, we’re adapting our firmware to new electronics and preparing everything for internal testing. One of the key features is the communication system (think something similar to Plug and play) for the expansion board and tool heads. This process needs to be fully automated, so every time you attach a new tool head, the system will recognize it automatically and assign the correct address to it. The XL uses a completely different system compared to our current models, where the mainboard of the XL needs to communicate with tool-head boards – these small boards contain, e.g., loadcell sensor electronics, so the communication channel is pretty busy, and especially the loadcell sensor requires ultra-fast response times.

We’ve also prepared a handy FAQ for you, so check it out at the end of this article. We’ll be back in several weeks with more updates about the XL’s development. 😉

FAQ:

Orders / e-shop

Q: Will I be able to change my selected tool heads / printer type / payment method / add extra tool heads and materials / change the shipping address etc. before the order is shipped?

A: Yes, by paying the preorder fee, you have secured your place in the queue and your order remains editable. Shortly before your printer is shipped, you will receive an e-mail from us with the request to finalize your order – you will be able to add extra items, change the number of tool heads, change your shipping address, payment options, etc. There’s no need to modify your order right now, please wait for our e-mail.

Q: What is the expected shipping date of the first batch?

A: We’re aiming for Q3 2022

Q: What are the shipping costs for the XL / for the XL with multiple tool heads / for the XL with multiple tool heads and extra filaments?

A: At this point, we cannot estimate the numbers. The shipping rates can fluctuate (e.g., due to the Covid-19 pandemic), plus the hardware of the printer and tool heads is not finalized, which means the final weight may vary. On the other hand, the preorder system gives us more options – we can, e.g., send a large batch of XLs to another location and distribute them from there, which brings shipping cost savings.

Q: Can you tell me what’s my position in the queue?

A: We don’t want to share this information to prevent trading with orders. Once shipping starts, we’ll publish a shipping table with specific dates.

Tool heads / Tool changing mechanism

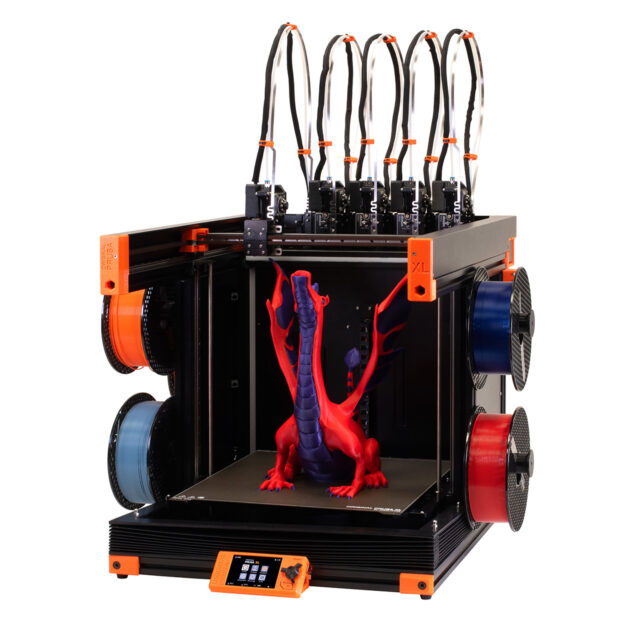

Q: Will it be possible to upgrade the number of tool heads after receiving the printer?

A: Yes, however, if you want more than two tool heads, you will need to install an expansion card (we will disclose more details about it in the upcoming months – pricing, availability, installation, size, ports, etc.). You can read about the tool changer in the previous article here.

Q: What tool heads will be available and how will they be priced?

A: More information will be provided later once we finalize their design.

Q: Is it possible to design your own tool head?

A: Yes, the design of the quick-swap mechanism can be used to attach a tool head of your own design. However, active tool heads will require users to write their own custom firmware

Q: Is it the E3D Revo / Hemera system?

A: No, we’re using a different (custom) design

Printer dimensions and build

Q: What are the dimensions of the XL?

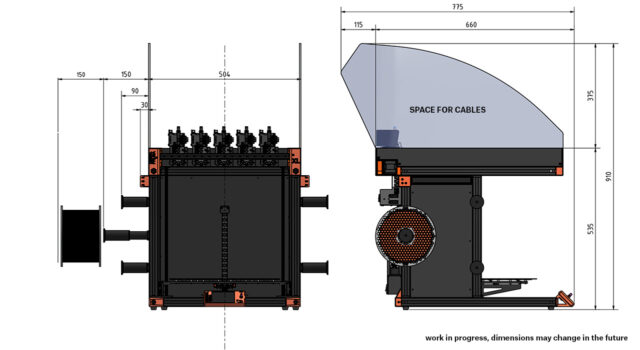

A: At this moment (!), the dimensions are as follows:

Excluding spoolholders: 504 mm / 19.8 in. (w) × 535 mm / 21 in. (h) × 660 mm / 26 in. (d)

Including spoolholders: 804 mm / 31.6 in. (w) × 535 mm / 21 in. (h) × 660 mm / 26 in. (d)

However, this is only the machine itself. The printer requires extra room around it for correct operation (e.g., space above the printer for PTFE tubes, space on the sides to place/remove filament spools). This is why you should have a space of at least these dimensions to comfortably run the XL:

1100 mm / 43.3 in. (w) × 910 mm / 35.8 in. (h) × 775 mm / 30.5 in. (d) – this is the absolute minimum of space you need to have on your table or shelf to run the XL without issues.

Please note that the dimensions may still change.

Q: What is the print area?

A: 36×36×36 cm (14.1×14.1×14.1 inches)

Q: What is the largest spool the XL can hold?

A: The default spool holders’ width can extend to up to 15 cm (5.9 in). However, you can design your own, if you need larger dimensions.

Q: Will there be an enclosure available for the XL?

A: We’ve already teased the additional draft protection and now we’re evaluating the options for the upper cover for the printer. The combination of the draft protection shield and the upper cover would work as a passive enclosure. We’ll share more information later.

Q: Will the XL be stackable like Prusa Pro AFS printers?

A: No, the XL will require some overhead clearance due to the way the tool heads are connected to the machine.

XL Tech

Q: Is the XL compatible with third-party nozzles? Does it support hardened nozzles?

A: Currently, the XL uses special nozzles in the Nextruder and we’re aiming to provide both standard and hardened nozzles at launch. We expect that third-party nozzles will appear on the market shortly after the launch due to the open-source design.

Q: What is the maximum speed of the XL / How much faster is it compared to MK3S+ / What is the recommended printing speed?

A: All these numbers are being currently adjusted and tested. As we have stated in the previous article, the point of the XL isn’t in beating the SpeedBoatRace. We’re aiming for reliability and high printing quality. However, for those who are looking to find the limits, we’re considering allowing the installation of Klipper firmware (not officially supported from our side).

Q: How loud / quiet will it be?

A: This is largely dependent on the printing speed – see the question above.

Q: What are the max temperatures for the nozzle and heatbed?

A: The nozzle is still being adjusted; the heatbed is generally the same tech as the MK3S+, so the heatbed temperatures are the same.

Q: How well does the Nextruder work with flexible filaments?

A: We achieved excellent results with our testing units 🙂

Q: Is it possible to use multiple nozzle diameters during one print?

A: We’re currently evaluating the pros and cons of a multi-diameter setup, it is something that is on the slicer’s side.

Multiple nozzle diameters would be fantastic! Please make it happen!

Yes. I’d like to print with .8 for infill and .25 for surface.

(My advice would be to use a smaller nozzle diameter than 0.8 mm for infill if the goal of the infill is to achieve strength while not wasting material. The filament tends to end pretty fast with 0.8 mm. 😊)

Now that is going to take time, swapping the printhead for every layer of infill…

Or not… you could do one massive 0.6 infil layer every 3 layers

I’m sorry, but that’s just wrong. Nozzle diameter and layer height are two completely separate things. Usually you do a 0.2mm layer height for a 0.4mm nozzle, so I fail to see how a 0.6mm nozzle would allow you to only do an infill every three layers. (0.6mm nozzle would probably then be 0.3mm layer height?)

Never mind, I think I misunderstood your comment.

Depends on how fast the XL changes toolheads, but if you’re printing really fine external perimeters and fat infill could still work out in favour of toolchanging, plus you could use eg cheap natural colour polymer for infill and more expensive pigmented polymer for the external perimeters (silk PLA and normal PLA for a simple example).

I think it would be a serious shortcoming if it didn’t allow for different nozzle diameters on the different heads. I guess it should be asked- can you use different materials in the different heads, or do they all have to run the same material? I’m surprised that the different nozzle diameter question isn’t met with ‘of course’….

I suspect that if you could do different diameter nozzles it should (theoretically) be possible to do different materials, but again they would be entirely dependent on slicer support. Nothing stops you from doing a color change on an MK3 today and swapping to another nozzle, except that you would need gcode that adapted to the new settings (flow rates, etc) so in practice it’s not a thing that most people do.

But the problem with different materials may have less to do with the technology of the printer (or slicer), and more to do with getting different materials to properly adhere to each other. And that may be a challenge for which there is no good solution at the moment. Some combinations may work better than others, but it’s a chemistry/physics problem at that point.

Different nozzle diameters event if you didn’t use them in the same print would save you from having to swap out filaments between different prints.

How quick is it to switch out a nozzle diameter in the print head?

I do agree that being able to use different nozzle diameters on different heads is “a must” feature. Being able to use different filament per head would be a HUGE plus and an argument for buying an XL instead of building a Voron.

Don’t know why it shouldn’t work. 2 years ago on my custom IDEX printer with 2 different nozzles, I was able to generate Gcode in Prusa slicer

So excited about the update! I’m very surprised to hear that it isn’t the E3D Revo, and thrilled to hear that hardened nozzles will be available.

I have a lot of ideas about tool heads I want to make. I want to make a plotter, a coordinate measuring probe (hobbyist CMM) for 3D scans, and maybe something to insert magnets or other objects mid-print!

What’s everybody planning to have slotted in for nozzles? I’m thinking about two 0.6 for most prints, two 0.4 for models that depend on it, and something small for text.

I would love to use multiple nozzle diameters in a single print! Having a nozzle just for printing text would benefit my workflow a lot.

Having the option to switch between a .4 or even .2 for detailed prints but also have a .6 available will definitely up my speed and workflow for larger prints.

I, for one, am really glad it isn’t based on the Revo, but is instead an open-sourced design that allows third-parties to produce nozzles for it without paying license fees.

This is, IMHO, so important. I understand why Revo decided to go the proprietary route and if that’s what they needed to do to stay in business, then good for them. At the same time, open source hardware is a net good for the consumers/users and it means a lot that Prusa continues to innovate but also open-sources their work. That’s something that I can and will get behind. This is a company I want to succeed.

“We expect that third-party nozzles will appear on the market shortly after the launch due to the open-source design.”

I can’t even begin to tell you how happy this makes me. With the Revo, I was afraid we’d be moving towards a situation where each company would make its own proprietary, patented system that only works with its own licensed nozzles. I hope that, whatever this new nozzle design is, it can become the new standard we all agree to use going forward, so that there is a huge market that allows niche nozzles from small companies to exist.

Do you plan to use XL for your production?

And do some multicolour parts.

I thik that is peretty important that you get real life experience for multicolour parts in your production.

When you do multicolour print it would be nice to have colour information in printing file. And if there is different size of nozles its even more important.

Then printer can say that

1. extruder nozle: 0,4mm Filament: PLA Prusament red

2. extruder nozle: 0,8mm Filament: PLA black

3. extruder nozle: 0,8mm Filament: PLA white

…

Novadays colour information is just in your head.

If you want print again something what you print last month. You need to do slising again because you dont know correct order if filaments.

I always put the colors in the filename (Object Name 1-Red Prusament PLA,2-Yellow Prusa PLA, etc, etc) that way I always know what filament is expected where in the MMU2S.

I’m less interested in the speed of the printer and more in the volumetric flow. I print predominantly with large nozzles so I need volumetric flow, not speed. Any idea what the cubic mm per second capability of the hotend is?

I’m with you here. Detailed work goes to the resin printer.

For my FDMs, I’m looking to print large objects and usually with big nozzles.

I had a printer with a silicone wipe blade and waste bucket. Wasn’t a big deal to empty every so often (and if you forgot some crap fell in the back of the printer I even saw some mod that had a funnel around the box to catch that and drop it outside). But if they can solve it otherwise, that’s fine with me. Space wise that’s a big area, but it’s going in place of the gMax 1.5+ which was a big machine (which basically never worked, and by this point I have replaced almost the entire printer) so pretty sure it will fit in that space.

Thank you for the update. The progress and the evolution of the specs are very promising. The ability to use tools other than extruders, alone, is revolutionary and opens so many possibilities!

Its not a new idea to have heads that do more than 3d print. I know of 2 other companies been doing that for some time. however they are primarily small CNC milling machines using small router heads for wood and soft milling and you can change them out with a laser head. At least 1 of them at the time I was looking at them claimed to be able to add a 3d print head but I did not see that run. I found that they tried to do too much and that made the machine usable for lots of stuff but not great at any of it. I am confident that if Prusa releases a head on the XL that will do milling or laser or something else, it will work well on a excellent printer.

I’m wondering if that would require a bed cover or other modification.

Will this new easy tool changing design be retrofitted to be available for the MK3S machines perhaps ?

Will it be possible to fit the Nextruder to other printers? I’m currently planning a toolchanger build that the XL wouldn’t quite work for, but very interested in exploring the possibility of using Nextruders in it, particularly with the load cell.

I would like to stress how much I would LOVE for the slicer to support different diameters for each extruder. I have a regular ongoing project that prints face down on the bed, and I print an inlay into it. It would be much better to be able to print the inlay with a 0.25 nozzle, with the rest printed with a 0.4 nozzle. Pretty please!

Thanks for the update.

Is the filament feed path compatible with locating the reels under the printer to reduce the width requirement?

I was going to ask the same thing. I have more scope on height than I do width. Locating them above might also be another more accessible option.

You can always add a few rollers and redirect your filament from, well, anywhere. Why should that be a problem?

yea I like to run filament from a de-humidifier.

Keep in mind that many work surfaces are only 23 or 24 inches deep and that there may be a wall in the back of that surface.

This is important for placement of printer landing pads/feet.

In other words, there isn’t carte blanche on the depth, but there is in cantilevering outwards in free space from a desk or table surface.

Thanks for the update. As far as I’m concerned take the time needed to make it right. What with the state of the world in your neck of the woods I can wait. Let’s hope it doesn’t escalate into something worse.

I also appreciate the update, it’s nice to have a quick “Yup, we’re still working” once in a while.

I’m still very very very curious about one thing: if you have two print heads, both loaded with the same filament, can the second take over when the first runs out of filament? That is my biggest single point of frustration right now; I have to keep records on how much filament I’ve used by hand in order to avoid sending something that’s too big for what’s left. Having the second print head just take over wouldn’t solve every single problem but it sure would reduce them!

This is already possible with there MMU2S which swaps between up to five filaments.

I really hope it would be a feature they bring over to the XL.

“You can use the MMU2S feature of filament depletion, called SpoolJoin. This feature will automatically switch to the next filament in line, should you run out. In order to activate it, go to LCD Menu – Settings – SpoolJoin [On/Off].”

I just want to add here, if you are using a MK3 with the filament runout sensor, the print wont fail when the spool runs out, itll just pause and allow you to put in new filament. Ive used this multiple times to use up the last of the roll and it works great. Ive been doing a ton of printing and have not had to worry or track spool usage with my MK3

Interesting how optimistic you guys are regarding solving Prime/Wipe. In my experience you can’t do clean MM prints without a very reliable prime/wipe setup (a purge tower is not a solution here). Seems to me relying only on nozzle cooling and retraction is a simplistic approach which I’d doubt will work all that well. Good luck with that!

“Q: What is the expected shipping date of the first batch?

A: We’re aiming for Q3 2022”

Thats now about SIX MONTHS.

In my experience as a PM that is NOT enough time. Especially since you have changed the processor, modifying FW, have not actually started making the boards yet and will likely have supply chain issues! This also assumes you already designed your production and verification processes (which I doubt).

If you expect to start deliveries in six months you should be much further along in the process.

What you are saying certainly isn’t incorrect. However, it sounds like most everything is being done in-house, which means the team can dedicate as much manpower to solving these issues as needed. It sounded like they were about to start testing, which indicates that they are clipping along nicely. July, August, & September… still a solid 4 months to go before the first wave needs to go out. From what I know of Josef from the times I’ve met him, entirely possible!

“Q: Will it be possible to upgrade the number of tool heads after receiving the printer?”

“A: Yes, however, if you want more than two tool heads, you will need to install an expansion card…”

For a lot of electronic projects I use the CAN bus. Very flexible, no need for extra board when you add devices. Why you don’t use this bus? It is cheap and reliable.

Can we expect the new hotend/nozzle system to come as an upgrade option to other Prusa printers in the future?

I’m considering upgrading my mini with an E3D revo, but I’m not sold on the closed off ecosystem and having an official option from Prusa directly would be quite nice.

Workbench has been redesigned and built to accommodate this big printer. Worked out well as it was time for a cleanup and printer area redesign anyway. Plenty of space now! Now to wait for my Christmas present (XL).

Will the plastic parts survive active-heating enclosure temperatures of up to 50 Celsius?

What are you printing at that temperature?

ABS/ASA generally prints best at those kinds of temps, or higher.

I was considering to order one of these printers. But when I saw the price climbing up to 4K when ordering a multi material upgrade I reconsidered.

That’s kind of like saying you wanted a new Porsche, but you found out they were over 30k so you are out. This is a precision machine built for performance, you have to spend on parts for it to be any good. As someone who was looking into a Voron this seems like a totally reasonable price for what you are getting. I would have spent similar amounts on a Voron 2 and would still have had to spend many of my own hours building it. I’m sure Creality would be more than happy to sell you an Ender 😛

This would be a Porsche with base price of 100K and another 100K for all the interesting extras. In my opinion, that’s way too much.

Yep. if you want the best Porsche out there (Porsche 911 GT2 RS) you’re going to have to fork out $293,000 for it.

What other printer has this build volume (14.1 in cubed) for this price?

What other printer has these options for this price?

If you want both (a fully decked out printer), then yes, you’ll have to pay the price.

It’s only worth it if you’ll use it. but if you use it, the outcome will be incredible!

This is wonderful news, but I’m wondering where I’m going to put such a massive printer, especially if I will eventually need an enclosure. Any chance there will be a slightly smaller model coming out with just 2 or 3 extruder capability?

With the work that is going into this, I can only assume it will be the new standard. Eventually, all the printer sizes will run this software & hardware.

I agree. I would love this ad on too. Very interested in it.

Can’t wait!

I am hangin’ out for the XL model. I am hoping for a more refined 3D printer than many on the market.

At the moment it looks like I will need to pair it up with a Voltera V-one to meet most of my perceived needs. The one need I can’t fill with those two is CNC machining.

But I am intrigued by the logical possibility of having a print head for the XL that can layer silver ink to make PCB tracks onto a 3D model. But of course it’s a problem to cure the ink and make soldered connections due to the high temperatures that would be needed.

I think that there are enough new features in the XL for me to wait until it becomes available to buy my very first 3D printer.

Hi, will there be some sort of filtration enclosure option to reduce fumes? I think even with your draft protection and upper cover combination, adding a filter/fan should still be able to offer some benefit, even if it’s not completely glass sealed. Thanks!

I really hope you guys allow multiple nozzles in one print. It is HIGHLY requested amongst the comments.

I would love the ability to switch to a smaller nozzle, being able to add small details could make my prints a lot more functional.

Just being able to add something like a small graphics of a blinking light to indicate a button is for brightness and still being able to print the rest with a larger nozzle could really round out my projects.

My cheap sub $700 flashforge creator pro 2 even has the ability to use different nozzle sizes for different heads.

Thank for your article. I resolved my problem. Definitely return here. https://krunkerio.io

I’d really love to purchase one of these but my space is limited. The space required for the cables at the back of the printer is a deal breaker without major headaches. The depth of the printer would just fit in perfectly in the area I have free but any more and 🙁

How necessary is the space at the back behind the printer?

I’m surprised at how long the cables are actually given that the gantry only moves in the X & Y direction. They look more than long enough.

Here’s hoping that they’ll be shorter on the final product and the rear space won’t be required!

I am having the worst time on my Mk3 trying to get large box prints (235mm in one direction) to NOT start warping/peeling corners. I’ve tried and tried and tried dialing in first layer cal, cleaning and temps, but I can’t seem to get it to stay half the time. Is this something that will hopefully be improved?

Side question, will there be a textured bed? 😍

Is there an approximate delivery date for orders placed now? The listing says 2023. Should it be expected i Q1 of 2023, Q2? Later?

I read somewhere that they were expecting Q3. So while we hope that means July, you should expect that to mean the final days of September.

Hi,

one feature that is very important to me is to be able to do large volume ABS (plus) prints. Unluckily this is not doable with the MKs model as the cooling system fails with temperatures over 40C.

Is it planed that the XL will be able to work in an heated enclosing at 60C (or hotter) so large scale ABS prints, for example are finally possible with a Prusa?

Is there any way to mod the MKs so its capable to work in an enclosing at high temperatures?!

Have this question as well. Can it print large volume ABS?

This machine is perfect for large nozzles, and when it comes to larger nozzles print speed is nowhere near as important as volumetric flow. Please let us know what the volumetric flow will be.

Hello Prusa!

It is June 4. Time for another update on the Prusa XL!

Thanks!

John

Agreed. Time for an update – what’s the latest on schedules?

I have engineering projects, and research papers abstracts submissions, depending on this machine’s capabilities – am not looking to print Benchies and Baby Yodas as its purpose in life.

So, need to plan resources & schedule and cannot when there’s silence from a key vendor like this.

Prisa Research would be taken more seriously by industry and prosumers if you provided monthly updates from this point, particularly since you’ve left it as delivering the XL next quarter.

thanks

If something is that important to you, then surely you need to look at what options are available now, not at some stage late this year or early next?

You have left us in the dark. As time goes by without news from you, we start to get nervous and out trust begins to wear out.

Keep us informed and you will have a happy customer base.

Hi, everyone. Very excited about the printer, which is making me unreasonably impatient. I want to make it as clear as I can, I would rather wait another year for the printer and have it achieve its amazing potential, so please, please take your time and get it right. I’d hate to think I was pressuring you into releasing an unfinished or rushed product. But, at the same time, I’d love to know how the development is going. We’re almost a month into Q3, and it’s been 3 months since the last Dev Diary. Currently, the expected shipping date is a maximum of 2 months away, and definitive specs are still thin on the ground. Is it time for another update? Even if it’s just: “it’s taking longer than we planned, folks, and we need to put the project back a couple of months”, I would love to know. Equally, thanks for progressing the FFF hobby market, which seems to have stagnated since you developed the i3, which was so good, everyone else just thought they’d clone that; you seem to be one of the few companies progressing the field in a meaningful way; and kudos for keeping things opensource, again letting the market develop. Apologies, if I am jumping the gun, but I’m on tenterhooks to know more.

Sorry, got my dates wrong, didn’t I? We’re not in Q3 yet, makes me feel a bit better. Still, can’t wait for the next update.

I think the draft protection accordion and a top shield are good ways to maintain the temperature. But… I was looking forward to a more advanced enclosure with a HEPA filter, and temperature control by means of fans venting heat out or holding it. So that even ABS is not a problem in the studio. I think that I am not alone in wanting this kind of enclosure. Would you consider building something like this?

Given the already-high pricing for the Mk3 enclosure, you might be much better off building an enclosure/heater/filtration system yourself. It’s a fair bet that people will be publishing their DIY plans for that kind of thing fairly soon after the printer is released.

I’m on pins and needles hoping for an update soon. Maybe beginning of July / Q3 we will get an update? I did not preorder right when they opened up so I doubt I’ll get a printer this year, but I am hoping for more information. I have one company that would really love multicolor prints and I’m holding off on getting a different solution since I have this preordered. There is no deadline for that and I haven’t made any promises but I want this for my personal use as well. Just excited and looking forward to hearing and seeing more.

My biggest concern regarding the XL is the timing: right now, as the day of writing, none single YouTuber has an XL, no one has written any review about a prototype, or any other source of real world usage of it. In the other hand we have the Bambulab Carbon X1 that is going to be shipping next week and have a ton of videos and articles talking about it. I know that both are very different machines for different goal-market, but the hype of having the next Prusa 3D printer is overshadowed by the fact that by the end of the year 2022 it’s when I’ll receive the first review, next year some bug fixes from the first and second batch and maybe by the end of 2024 we will have a final version, without any hiccups, like the MK3S, where all other improvement can be made if we want to instead of need to.

C’mon, guys. The silence is deafening. Will you not even acknowledge our pleas for an update by giving us a hint of when you’re planning your next announcement?

Are there any new updates on the XL. I realize you are busy chopping away at design and build issues and not to mention bug fixes however this last diary was almost 4 months ago. Any information would be greatly appreciated.

Not surprised there is nothing to share, since they are still waiting on critical parts…

Hi, gruagach,

I genuinely didn’t know that. It’s the sort of thing I’d really like to know. If there are problems, and I know about them, I can handle that; especially with the world being so crazy at the moment. When I say I’d just like a progress report, and don’t really mind if things have to be pushed back a year, I really mean it. What I hate though, is radio silence. How and where are you getting your info?

Hi, gruagach,

I genuinely didn’t know that. It’s the sort of thing I’d really like to know. If there are problems, and I know about them, I can handle that; especially with the world being so crazy at the moment. When I say I’d just like a progress report, and don’t really mind if things have to be pushed back a year, I really mean it. What I hate though, is radio silence. How and where are you getting your info?

I also understand complete silence with no hint of updates sucks. I just don’t want to see this happen with XL the same way simplify 3D has and still is doing. Hell I cannot even remember how long ago (years) they claimed an update to the software but nothing. People can understand delays more if they know what and why.

It would be nice to get some new information about the XL project. We have now Q3 of 2022. And i know it’s hard to get eletronic parts for a project like these.

Welcome to August.

What is the reality of seeing these launch in the next 60 days?

SoCalSteve, that’s the thing, isn’t it? My guess is they’re really close, and will make one final announcement soon, or still really far away, and have nothing to say. Either way, it’s hard not to become a bit agitated after nearly 4 months of silence. It’s hard not to come to the conclusion that Prusa is treating us with utter contempt, asking for a $200 deposit, then completely ignoring us for so long. I’m beginning to feel insulted. I just want an update. It’s less than 2 months until the shipping date claimed by their sales website, and we still don’t know what sort of print speed or flow rate we can expect. If they say that the project has to be pushed back 6 months, or even a year, well so be it. I’d be fine with that, it’s understandable, with how the world is today. This was a prototype, when I signed on, and I, frankly, expected delays. But, to leave us completely in the dark after asking us to become invested, is just not on. I’m seriously considering cancelling my pre-order, and buying something else instead. The Bambu X1 looks like a good printer and is half the price, and the Vorons or RatRigs are also look like excellent printers, and have run the test of time.

I’ve just chatted with customer support, and they say a new Dev Diary is being written, as we speak. Josef has announced this on Reddit a week ago. Why he didn’t say the same thing here, on Prusa’s own website, I really can’t fathom.

Here’s the link: https://www.reddit.com/r/prusa3d/comments/w5h4bn/comment/ihks5cx/?utm_source=share&utm_medium=web2x&context=3

I purchased 1x 13MK3+ to try, and I loved it, (even after 2 blob outs).

I found your Technical support fantastic 9. Spent another 4k for 4 more machines and then came up against this administrative nightmare. Your wonderful product and fantastic technical back is detroyed by your totally incompetent admin who have no hurry at all to take care of issues. I have to go elsewhere with my business. With regret. Lennart GAIA

January 2023, have units started being delivered yet? I have a mini and am looking to get a 5 head XL! So keen!