As you may have noticed, our last Prusament announcements have been generally quite big news: they were not about mere new colors but about non-standard and specialized materials (PVB, PC Blend Carbon Fiber, PA11 Carbon Fiber, PETG Tungsten 75%). Though it may not look like it at first, this time it’s even bigger! We’re launching the one-in-the-world UL-certified self-extinguishing PETG filament. So why is it such a big deal and what is it good for?

Self-extinguishing vs. fire-resistant

First, let’s take a look at what the term “self-extinguishing” means. The self-extinguishing material has usually mechanisms that slow down and eventually stop the flame after it starts burning in the first place. When our Prusament PETG V0 starts burning, it creates a carbonized crust on the surface that prevents the oxygen from getting in and fueling the flame and eventually extinguishes the fire. On the other hand, fire-resistant materials are hard to set on fire in the first place.

The UL certification meaning

In short: the fact that we obtained the UL certification for our filament is a big achievement and a testament to the skills of our Prusament team. The UL is a global safety company that tests various products (materials and mostly electrical equipment) for different levels of safety certifications that are useful in both practical and legal implementations. Almost any product manufacturer can ask them to test their product. The UL company serves as an independent element that guarantees unbiased results for every tested product. Their staff selects the proper testing method (ASTM, IEC, ISO, or other) and accordingly asks the product manufacturer to provide a complete set of test objects. Then, they run the tests in their laboratories and finally provide the certificate of compliance that serves worldwide as legal proof for the product.

We asked the UL to test the flammability of the self-extinguishing PETG marked as Prusament PETG V0. The test method was made according to the IEC 60695-11-10 standard and resulted in a class UL94 V0 (for both our colors, see below). Here’s the Blue Card that serves as a certificate issued by the UL company.

Blue card issued by the UL

What does the UL94 V0 flammability category mean?

The UL94 method applies to various plastic materials. It helps to determine whether the material extinguishes or spreads the flame after ignition. This method is harmonized with IEC 60695-11-10, IEC 60695-11-20, ISO 9772, and ISO 9773.

There are several subcategories for the UL94 method. Our Prusament PETG V0 follows the Test criteria for Flammability UL94 V – 50 W, 20 mm Vertical. In this subcategory, it got the best result possible, which is marked as V0.

The test was conducted on a set of 600 pieces of 127×12.7 mm specimen with various thicknesses (minimum is 0.75 mm for Prusament PETG V0). The specimen included samples printed in all orientations (xy, yz, xz) with both minimal and maximal speeds.

During the test, the specimen was set on fire hanging vertically. It was observed how long it takes for the flame to extinguish and whether the material drips and spreads the fire. The flame in this test was 20 mm high and the exposition during this test took 2x 10s (the second exposition starts right after extinguishing).

As for the criteria, the V-0 means that our test objects burned less than 10s after both expositions. The total burning time was less than 50 s after 10 flame applications, burning and afterglow after second flame applications were less than 30s, there was no dripping (and igniting cotton pad) and no total burnout of the specimen.

All of the criteria are described on the UL website.

What was the purpose of the certification?

Making the material certified as self-extinguishing means not only practical implications (simply by greatly reducing fire hazard) but also legal implications. In other words: If you want your part (product) certified as self-extinguishing, it gets a lot easier and requires much less testing when the material itself has the proper certification. However, even with us making it one step easier for you, you still have to follow some rules set by us and the UL company. This means that you need to print the models with the MK3S+, MK4, or XL printer with a 0.4 mm nozzle (0.2 mm layer height), slice it in PrusaSlicer, and use the prepared profile. Also, keep in mind that the certification applies only to objects thicker than 0.75 mm (2 perimeters). Not following the rules leads to the risk of losing the desired properties!

What else makes the Prusament PETG V0 unique?

There are other self-extinguishing filaments on the market. Some of them even claim that they can fulfill the same UL standard as our PETG V0. However, their manufacturers don’t offer any legal note saying that the UL truly tested it. The Prusament PETG V0, on the other hand, is properly certified and the final result is published on the UL’s website.

And there’s more. Not only the other self-extinguishing filaments are not certified properly but they may also contain some toxic substances that are released into the air when burning. We’re talking about halogens. The Prusament PETG V0 is halogen-free.

|

|

Who is it good for?

There are two main reasons why we’ve decided to go on a long and challenging journey to make a self-extinguishing filament with proper certification. At first, there is a large business sector, where the companies need to have everything legally right and require certified products. Our filament allows them to make rapid prototypes with the legal (and practical) requirements around fire safety.

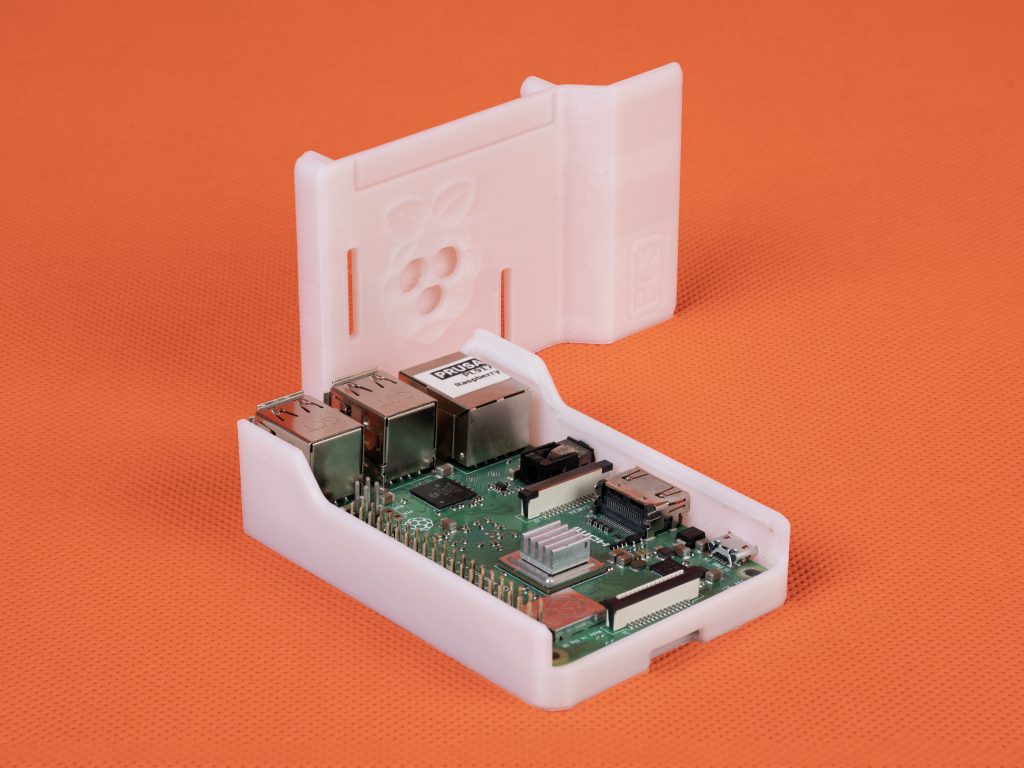

Second, we strongly recommend using this filament for making homemade electronic appliances. After all, accidents tend to happen even with relatively safe electronic products and if you’re a maker who crafts things by hand, you really want to make the products as safe as possible.

Colors, price, and printability

So far, we offer the PETG V0 in two colors – natural (white) and jet black. The 1 kg spool costs 54.99 USD/54.99 EUR (VAT incl.).

Compared to the Original Prusament PETG, the PETG V0 comes with slightly lower tenacity, and layer-to-layer adhesion. This filament needs to be kept as dry as possible as it’s more hygroscopic, compared to regular PETG. If you can’t keep the filament dry, we suggest drying it before use for 6 hours at 55 °C.

The Prusament PETG V0 is UL-certified only for printing with the Original Prusa MK3S+, MK4, and XL. Don’t forget to follow these three simple rules to get the best results, according to the certification:

- Use Prusament PETG V0 only.

- Print it with MK3S+, MK4, or XL 0.4 mm nozzle and 0.2mm layer height.

- For slicing, use PrusaSlicer with PETG V0 profile.

Examples of use

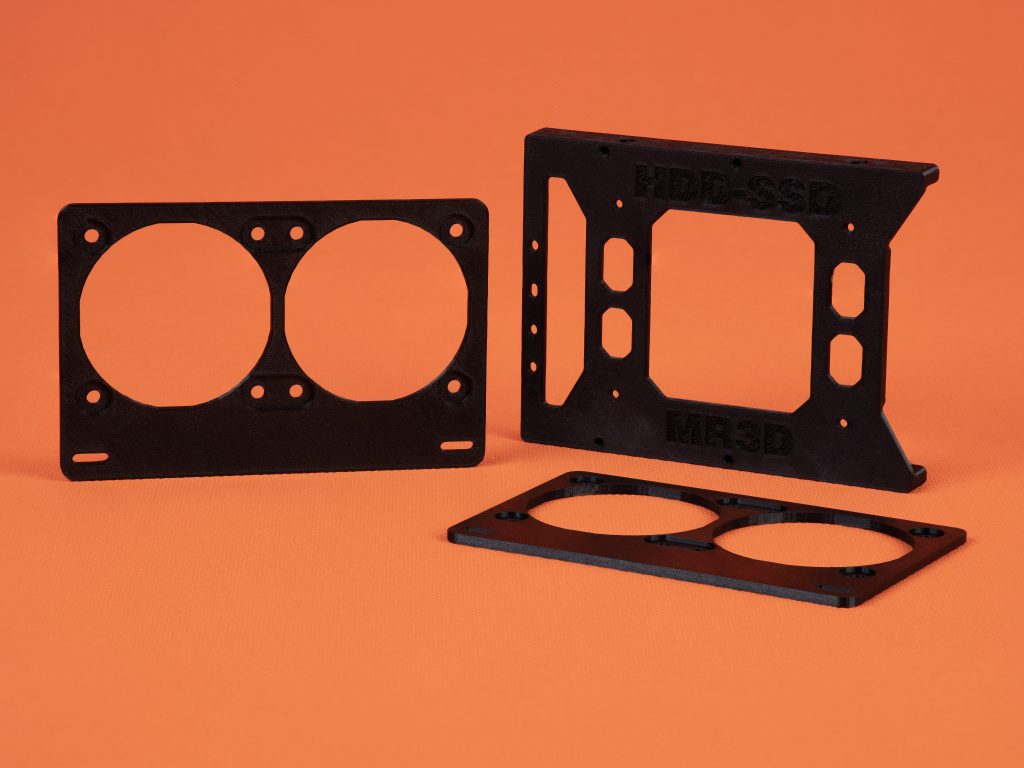

|

|

|

|

That’s all for now, we hope you’ll like this new PETG and as always, we’re looking forward to seeing your cool creations.

Happy printing!

Great work Prusa! Really looking forward to trying this new material out.

Does layer-height (and nozzle dimeter) truly contributes to the self-extinguishability, or these are simply prerequisites of UL (that they certify exact settings)?

Having some experience with UL certifications in my profession I can confirm your assumption. UL only certifies what they have seen and only in the exact configuration in which it was tested. So having the certificate only for nozzle diameter 0.4 or only for MK3S+… simply means that this was the test setup and this is what UL guarantes for. It doesn’t mean that e.g. a print with nozzle diameter wouldn’t pass a V0 test es well, it’s just, nobody knows before it was actually tested. And as a matter of fact sometimes very small differences in the manufacturing process can make big differences in the material properties.

Nevertheless that’s quite good news and i would encourage everyone to prefer this material for electrical enclosures and everything nearby electronical parts that could get hot or catch fire, even if the printing setup is not exactly as noted by UL because it’s very likely that it’s still better than other standard material with respect to flammabiliy.

Takto to na vzorku bylo zkoušeno a certifikát je vystaven přesně na toto použití.

Jiná tiskárna a jiná výška perimetru mohou prohoření stěny modelu změnit.

Pokud trváte na jiné tiskárně a jiném perimetru, musíte si zaplatit svůj test na jiných parametrech.

3D tisk může generonat na rozdíl od lisování ve formě spoustu netěsností a vzduchových mezer. Proto konkrétní tiskárny, konkrétní profil včetně výšky perimetru, konkrétní minimální síla stěny…

How does the fillament handle lithium fires

This filament is not a fire suppression product. It is designed to keep itself from spreading a fire. It won’t extinguish something else that is on fire.

“Handling” can mean different things though. The material would be approved as a fire barrier/enclosure for a device housing a lithium battery. Of course there are additional design requirements that come in to play, such as opening size and separation distance from the battery as well.

In the context of say housing Lithium cells within, with the material acting as a barrier to prevent the fire causing collateral damage. Then this material is highly suitable and a great fit for if you are thinking of something like a RC-project or (combat) robot in combination with high-power lithium cells. Or well, anything involving power really.

Just do mind some design considerations. Like a opening for gas to vent, If using Li-Poly pouches: Some room for it expand and ideally something like a Double-barrier (With FDM a thick wall with lots of perimeters and room inbetween them can accomplish that).

wait- whutt?? This isn’t standard for PrusaSlicer? Their promo pics show models made with soluble supports… you need to use a special build? Why isn’t this standard??

I understand the bit about Neststruder being a very different unit.

But what doers this mean if I have a Mk3S+ and a MMU3. If I upgrade the printer to Mk4 (or, presumably Mk3.9, as that also has Nextstruder….?)- am I going to need to:

1) Update PrusaSlicer settings?

2) Update MMU3 firmware?

3) Update MMU3 printed parts?

4) Update MMU3 hardware?

5) Some combination of these elements?

I’m actually very excited about MMU3 in combination with Nextstruder and the new Main/daughter boards for Mk3.5 and up!

good job! Some of the ways that can help you improve this is to change the color of the screen used. The white screen will be suitable when you watch movies or play games.

Vyzkoušeno !!!

První V0, která se snadno tiskne, při normálních teplotách (80/230°C) a bez vyhřívané komory. Od vlastností čistého PETG se nijak zásadně neliší.

Při testech jsem nezaznamenal žádné znaky tepelné deformace, kroucení modelu!

Povrch polomatný saténový, velmi slušný detail – nádhera.

Ještě by to chtělo šedou barvu, páč v elektrotechnice je to standard.

Skutečně přelomový materiál, snad bude i cena časem rozumnější.

It’s valuable information for everyone.I am expecting more information like this.

ig tools

I adore that you informed me about this article since I think it’s amazing. That is exactly what I was hoping to discover, and I sincerely hope you will continue to share such excellent stuff in the years to come. word wipe

I sincerely appreciate the information and advice you have shared. Thank you for sharing all this wonderful information.

<a href="https://igtoolsnetviews.in/">Instagram followers</a>

<a href="https://www.edgewall.com">key5</a>

Are there any specs on dielectric/ insulation qualities?

Can you add certification for use with the Core One printer? When will you get UL94 V0 for your ASA?

Hi there, I'm printing PETG V0 on a Prusa MK3S+ using the recommended UL print profile. Due to over-extrusion, I ran into an issue and had to adjust the extrusion multiplier in the profile settings from 1.04 to 1.00. Does the printed part still comply with the UL guidelines?