The year 2020 is finally over and I think it goes without saying that it was pretty tough for many of us. However, despite (or maybe because of) the new challenges, the 3D printing community grew even bigger and more active, and it was amazing to see people coming together and helping each other. It was a hectic year for us, so let me sum up what we’ve done in 2020! Let’s dig into the details!

2020 in Prusa Research

First of all, I gotta say that I’m incredibly proud of the entire Prusa Research team. In spite of the ongoing COVID-19 pandemic, we managed to create and maintain a safe working environment for our team, so the entire production could continue running pretty smoothly. We came up with a list of anti-COVID measures and I’m really happy that all of us stick to them responsibly. A lot of people probably thought that it is almost impossible to achieve something like this in a manufacturing company environment like ours. I believe we proved them wrong, though. With the pandemic getting worse across the Czech Republic, we used to say that (figuratively speaking) it’s safer to be at work than at home.

Of course, there were some cases within our team. But as far as we know, there wasn’t a single COVID-19 transmission at our workplace – even though there are more than 600 of us now. Sure, there were some hiccups along the way, like the shortage of certain components we use to assemble our 3D printers. However, this only accelerated our plans to manufacture more parts in-house (e.g. our own injection molding production lines).

And we really needed all hands on deck, because our activities unexpectedly expanded beyond our usual 3D printer manufacturing. To help fight against the COVID-19 pandemic, we designed the open-source Prusa Face Shield, so we could kickstart the worldwide effort to provide frontline staff with 3D-printed personal protective equipment due to the major shortage of PPE in stores and warehouses. It was (and still is) an amazing collective community-driven effort that brought people together. We produced over 250,000 face shields, which we donated to frontline staff in the Czech Republic. There are probably millions of 3D-printed shields still used all over the world. Even today, when you see photographs of medical professionals, many of them wear 3D-printed face shields, shields provided by the 3D printing community. Thank you, everyone, who decided to help!

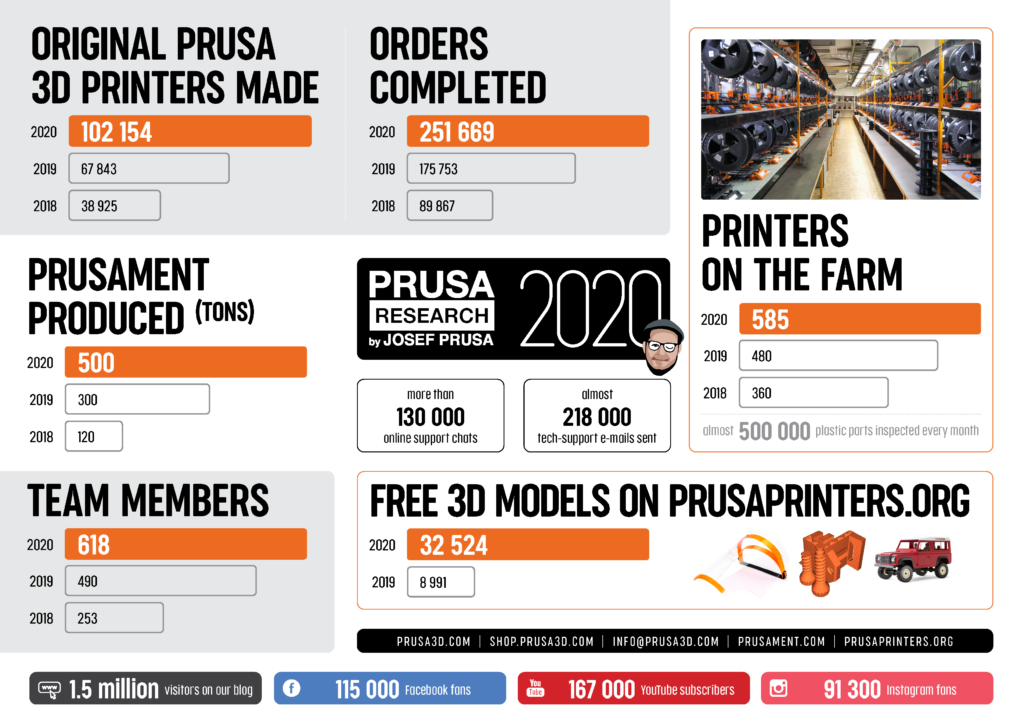

Of course, we kept manufacturing our 3D printers and filaments. In 2020 alone, we’ve managed to ship an incredible number of more than 100,000 3D printers, over 500 tonnes of Prusament, and hundreds of thousands of small orders (like upgrades, spare parts, and accessories). Two updated 3D printers started shipping – the MK3S+ and MINI+ with the new SuperPINDA sensor. We expanded our print farm to 585 3D printers, launched 15 new Prusaments, released 8 firmware updates for our machines, we even started our own live stream show to give you a bit of behind the scenes looks into what’s cooking in our development kitchen to offset the lack of worldwide events. 🙂

All in all, every time I say that the last year was pretty crazy, the next one is even crazier. So, I guess 2021 will keep this tradition going. If everything goes well, we’ll launch four new 3D printers, new services, firmware updates, and more. Take a look at what we managed to do in the past twelve months.

2020 timeline – month after month

JANUARY

- The release of firmware 1.3.0 for the Original Prusa SL1 with full localization to 7 languages, OTA, user resin calibration and more

- The Original Prusa i3 MK3S received „The best all-round 3D printer“ award from TechRadar.com

FEBRUARY

- The beta version of our brand new Knowledge Base has been launched at help.prusa3d.com, including PrusaSlicer documentation

- Basics of 3D Printing e-book was published in all seven languages on our website. Everybody can get it for free in English, German, French, Italian, Spanish, Polish and Czech.

- Prusament PETG Clear and PLA Royal Blue launched

MARCH

- A huge PrusaSlicer 2.2.0 release with SLA hollowing, support for 3rd party printers and much more.

- As the Covid-19 pandemic spread in the Czech Republic, we have started the production of our own disinfectant – back then, the availability of standard disinfectants was very limited.

- Three days after the original idea we have released the first version of our face shield and started the distribution to the front-line staff in the Czech Republic for free. During March, we’ve donated over 25,000 face shields.

- The members of 3D printing communities worldwide reacted to our initiative and also started the distribution of face shields in their countries. To help them organize their work and coordinate their efforts, we have launched the user groups feature on our community website PrusaPrinters.org.

- The MK3S is still the best 3D printer according to All3DP in their spring update (and it’s still there in December, btw – thank you! :).

APRIL

- Firmware 4.0.5 for the Original Prusa MINI released with the first version of Prusa Connect Local, improved MBL, and more.

- 120,000 face shields donated to the hospitals and doctors in the Czech Republic by the end of the month

- Prusament PETG Prusa Orange for PPE launched to help the 3D printing community with producing face shields

- The MK3S is the Best 3D Printer according to WireCutter (New York Times)

- The barbershops in the whole Czech Republic are closed due to the pandemic, so we have decided to open our own internal Prusa Barber Shop for employees 🙂

MAY

- Prusament PC Blend announced

- PrusaPrinters.org (including our blog) is now fully localized to all seven supported languages.

- A major release of the new Original Prusa i3 MK3S firmware. Version 3.9.0 comes with the Linear Advanced 1.5 and it implements 409 revisions, 108 pull requests, and closing 66 issues.

- As all live events have been canceled due to the pandemic, we have started our first Prusa Live stream and we are live streaming a new episode every 2 weeks.

JUNE

- We have got the CE certification for RC3 face shields and released the final Prusa PRO face shield. We have also shared our experience and published the guide on how to get certification for shields.

- 200,000 face shields produced and sent

- “Likes” for PrusaPrinters models added

- Prusament PLA Lime Green and PETG Signal White launched

JULY

- MINI firmware 4.1.0 released, adding sound alerts and automatic pause when the USB drive is removed.

- Autodesk endorses our Fusion360 guide

- Prusament PETG Pistachio Green launched

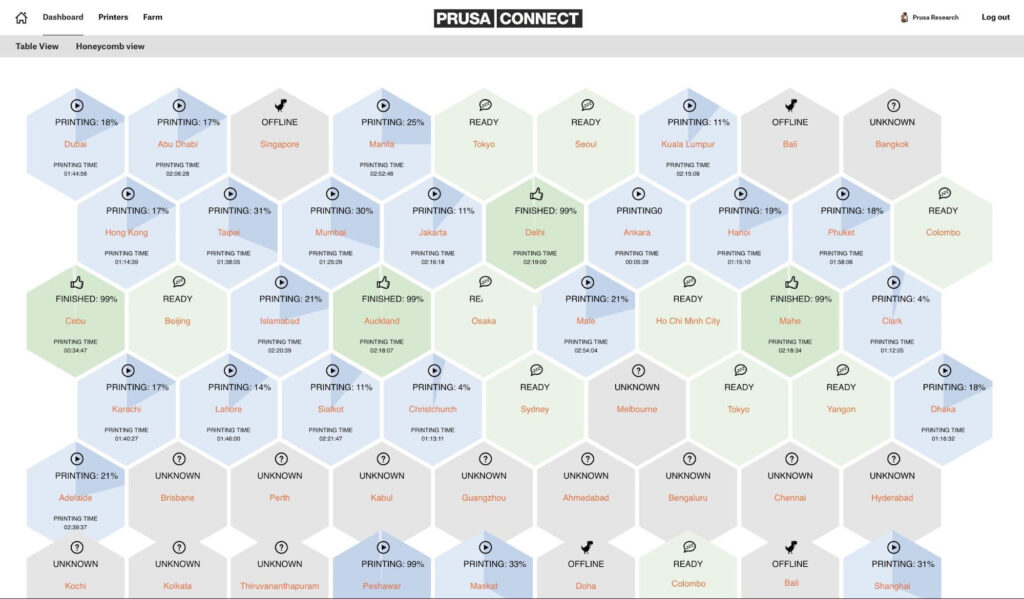

- Internal testing of Prusa Connect started

AUGUST

- Firmware 3.0.0 for the CW1 released. It brings the complete code refactoring, optimization and localization to all 7 supported languages.

- Firmware 4.2.0 for the MINI released with the localization to all 7 supported languages.

- Prusament PC Blend Prusa Orange and PETG Terracotta Light released

- We’ve got bees! We installed 10 beautiful beehives in the area behind our factory. There are many parks around and even vineyards nearby so they should be pretty happy. 🙂

SEPTEMBER

- Firmware 3.9.1 for the MK3S released with an improved LA 1.5 implementation.

- We have launched the initiative called “Prusa for Schools” in the Czech Republic – it supports 3D printing education and we would like to extend this program to more countries in the future.

- We were awarded by the Czech Red Cross with the Gold medal for producing face shields.

- 150,000 subscribers on YouTube

- Prusament ASA Signal White and PETG Chalky Blue launched

OCTOBER

- New filament material guide published at help.prusa3d.com

- 3D printing price calculator published

- Cooperation with 3D Sets – video and special 3D model of Landy Mini published on PrusaPrinters.

- Attended VERRF 2020

- Prusament PETG Anthracite Grey and PETG Mango Yellow launched

- Josef on the cover of the prestige Czech Finmag magazine

- 585 3D printers on our farm (with extra 60-70 backup machines)

NOVEMBER

- Original Prusa i3 MK3S+ and MINI+ announced and sent to the first customers

- We have released the first batch of the new Satin Spring Steel sheets.

- Our maker space PrusaLab has been closed to the public for almost a year. Meanwhile, we have transformed the lab to a custom workshop and we have started the Accelerator for Czech hardware start-ups.

- Prusament PLA Oh my Gold, Viva la Bronze, and PETG Ocean Blue launched

- 3D preview of models available on PrusaPrinters

- Official Prusa Discord channel launched

DECEMBER

- Black Friday / Cyber Monday deals bring huge success but, unfortunately, also increase lead times. We are working harder than ever to get them down as soon as possible.

- We have prepared our own in-house COVID-19 testing lab for all employees and their family members.

- Cyberpunk-themed MK3S draws attention all over the world – articles were published by PC Gamer, Tom’s Hardware or Windows Central.

- Emerging Tech Award for face shields (ASME.org)

- Notifications launched on PrusaPrinters.org

- “Reflection” (a kinetic sculpture made in PrusaLab) was displayed in Archa Theater in Prague – take a look at photos and videos of this magnificent project.

Our plans for 2021

And 2021 will be even bigger. First of all, we would definitely like to add some sheep and llamas to our bees. 🙂 But seriously. We have many goals and releases, so let’s talk about them. Starting with the bigger picture, we want to focus on vertical integration – basically making more things ourselves, in-house. This worked for us so well when we started to produce our own filament (Prusament) in-house that it motivated us to look at other potential areas for expansion. This process has the added benefit of learning new things from the ground up. For example, with our Prusament, we learned so much more about the polymers, that we can use this experience to make better printers. Speaking of Prusament, we are planning to add more extrusion lines this year to the 13 we already have. And we also want to release the first resins developed and manufactured in-house.

You might have already seen some signs of the next thing we’re planning: the introduction of some injection molded parts already present on the newest Original Prusa MINI+. It doesn’t mean that we are going to abandon our 3D printing farm – no way! But we are now building our own injection molding factory and it is not exactly for the reasons you might think. It is not cheaper for us to make injection parts. The thing is, we have a lot of plastic waste from either rejected Prusaments or rejected prints from the farm (it is mostly visual imperfections, but everything needs to be perfect), which we can use as a resource for the injection molding. And NO, making recycled filament is not an option. It is expensive for what it is and it is simply not as perfect as we want.

Actually, we’re starting a pilot project this year here in Czech to collect 3D print waste from universities and print labs. We will use it to produce injection molded parts, which take a ton of time to print (like the MINI’s front and back plates) and their design does not change. In fact, these two plates take almost half the time needed to produce all the parts for the MINI. The time we spare can be spent on using higher-quality print settings for the rest of the parts. This switch will happen in the next few months once we install everything. Right now, these parts are made externally to nail down the forms and gain experience.

The next thing is an in-house PCB assembly line. We’ve been designing all the boards ourselves for quite some time and this is the next logical step. Waiting for prototypes takes ages and it is often unreliable. Removing this bottleneck will speed up the development process immensely and make the boards cheaper to make. Even better, we could have more features for the same price 🙂

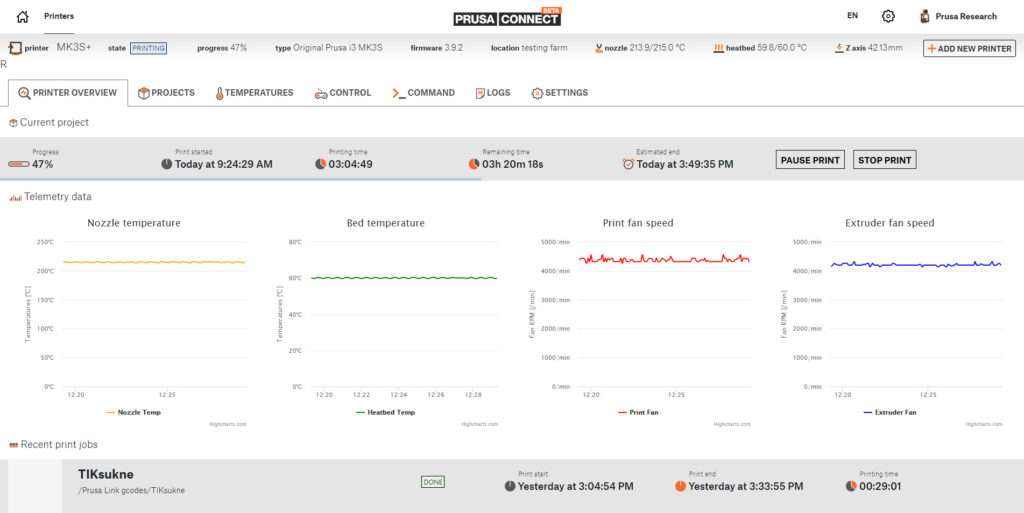

Now, let’s take a look at our goals in software development. First, let me shed some light on Prusa Connect (our remote printer management software), which is getting closer and closer. It’s currently in the polishing stage. And as usual, the 80:20 rule applies here heavily. The last 20 % takes 80 % of the time. A realistic target, based on our internal beta testing, seems to be March this year for public beta – it will most likely start with the MK3/S support.

PrusaSlicer has the 2.3 version just released and it will continue to roll this year. We’ve shared more info in an article that was published along with the release of 2.3.0. Our main goal for 2021 will be to have several smaller releases instead of a few giant ones.

Our community hub and 3D models database, PrusaPrinters.org, is growing faster and faster, showing no signs of slowing down. In fact, it grew to 4-times in the last year alone. It’s an incredibly important project for us and we intend to up the game even more in 2021. PrusaPrinters will gain more features and we want to transform it into a 3D models repository for truly everyone – so the support will go beyond Original Prusa 3D printers. No matter whether you own any other 3D printer, we want to make you feel like at home. And don’t worry, we’re ready to scale up our infrastructure as needed, so even with more users and more models, the web won’t grind to a halt. We’ll keep focusing on performance, UX, and reliability. And as always, we listen to your feedback. We’re planning to expand the community functions and add new options for the World map. One of them will be official Prusa technicians – users who will go through our training course can become officially licensed technicians. You won’t have to send a printer to us for repairs, you’ll just find a technician near you.

And now onto the printers! I am pretty sure you are all reading this to get more information on the XL but there is not much more I can tell you now. We’re still focusing on the structural strength, print quality, tool changing options and efficient operation. However, I think we can start posting some teaser print images pretty soon. And we will demonstrate our automated print farm (based on the XL) at the Dubai EXPO 2021 in Czechia house.

What I can tell you, however, is that the SL1 will get a larger brother with a mono display and the same build quality and ease of use. I think this becomes even more important on larger printers because the resin is expensive.

On top of that, we will have two more printers released this year, but it is too early to speak of those now. Stay tuned for more news, though! 😉

Here’s to a better, happier 2021!

For me, it’s pretty difficult to believe that mere 12 months have passed since the beginning of 2020. With everything that happened in the world, it feels so much longer.

I would like to thank everyone who is helping in the ongoing COVID-19 pandemic. A huge thank you goes out to the entire 3D-printing community. In 2020, all of us have shown an incredible sense of solidarity, responsibility, and cooperation. And that’s the only way we can overcome this unprecedented crisis – by working together. I wish you all the best in 2021. Stay safe!

Happy printing!

As someone who owns multiple printers, I can’t tell you how excited I am for Prusa Connect. Good work Joe and the team and thanks for all that you’ve done in 2020. Happy printing!

I am extremely happy with my i3 mk3 down graded from the mmu and downgraded from the “s”

I promote it and your support, to whoever I can. The best.

A big no-no was the mmu you brought out. Absolutely wasted my money and time to build. Not a feather in your cap.

Just standing on the top shelf with the gummy bears still unopened

Again my i3 mk3 printer is still better than the other two I have. One is converted to laser and one will be converted to dremmel cnc

Cheers

Harold

I installed my mmu2s and wasn’t able to get it to work right away either. I built the lack v2 enclosure, and essentially just used it for choosing a color on single color prints. From doing this alone, I was able to find the proper tolerances for tightening the screws on the tubes, and what things cause issues with the menu. I decided to print the multi-material bender from their demo files. I think it was about 700 filament changes, and it only needed my intervention 3 times.

It may be hard to get it running smoothly, but it’s like magic when you do.

The MMU2S can take a bit of work to get tuned, but once you do its fantastic. I’m printing a batman snowboard stomp pad (https://www.prusaprinters.org/prints/53550-batman-snowboard-stomp-pad) with my MMU as we speak. Zero interventions.

The key I’ve found to getting reliability from the MMU is higher quality filaments. I switched almost entirely from the cheapest PLA I could find to high quality PETG from GreenGate3D. I rarely have issues anymore.

The other mod is larger inner diameter PTFE tube from the MMU to the extruder. I went with 3mm ID, but if I had to do it again I would go with 2.5mm ID tubing so the tips shrink down slightly smaller on unload.

I think you should develop them better. Will help a lot at work

https://techtodown.com/tinder-gold/

Bravo!!!

Felicitaciones y gracias.

Great idea for the Prusa Technicians! I’m definitely interested. It can help increase community knowledge of the products, reduce shipping costs, reduce turnaround time for problems, reduce workload for your 600+ employees, etc! Now I just need to learn patience while waiting for my mini+ order!

I too am interested in the Prusa Technician program while i wait for my Moni+ kit 🙂

First of all, I would like to congratulate the entire Prusa team for the really awesome numbers! Also congratulations that the team has survived the pandemic so far well – I hope you all stay healthy! Also I would like to thank your support explicitly, really awesome!

For the year 2021 are really cool things on the agenda! Keep it up!

Awesome, prusa technician, where can I sign up? 😉

Me too! Absolutely interested in this!

Joe it was quite a year. The summary is quite an in depth chronicle. Your contributions to the world COVID response are remarkable. Even with the limits placed on everyone by the pandemic, Prusa Research still moved ahead in 2020. This year sounds very promising. The future strategies certainly make sense. I plan to sit back and enjoy all of news and new introductions as they are revealed.

I think the Eshop needs a refresh. With how clean and good the other parts of the website look, it just feels out of place.

That didn’t stop me from ordering my mini though – I’m very exited and looking forward to it!

We are working on the new e-shop already. 🙂 Thank you for your support!

Outstanding news! I can’t wait to hear more about the Prusa Technician Program — I’d love to be a technical reference for all the university folks like me who use these printers to drive their research!

Love Prusa and will never buy anything else. Congratulations on all your accomplishments! Look forward to see what happens with Prusa and it’s community in 2021.

It’s really incredible what Prusa Printers has achieved in the last year. For others it would take several years to achieve this. I really think the idea of producing more in-house is a very good solution. I can’t wait to learn more about the new printers.

any upgrades for the sl1?

These are really great news, really excited for the 4 new releases and even more excited about the Prusa technician program and I’m very interested into it.

I can’t wait for all these things.

Happy new year to all of you..!!!

Awesome work 🙂 Hopefully we will see some upgrades for the SL1 too!

Prusa Technicians.

Awesome.

I’m in!

Absolutely amazing recap.. well done. Great to see how open and honest Prusa is as a business.

Useful research. I like your strategy for dealing with the Coronavirus. During this difficult time, many spheres have suffered from the pandemic, and the education system has received the hardest hit. In a study from the BBC, it was revealed that in 2020, the progress of students in distance learning decreased by three. I also noticed that I became less productive. I think that for the duration of the quarantine, I need to find a good writing service that can help me improve my grades. Fortunately, services like OnlineWritersRating provide reviews of the best writing services, and I definitely won’t be wrong about my choice.

Well done, Prusa!

I wonder at what point 3D-printing the printer parts would become not cost effective.

I’m hoping the XL doesn’t become too overcomplicated. I need a bigger MK3, that’s it.

I agree!!

Oh @josephprusa, this teasing and then the wait to get more details. You really do seem to like torture. We will try to survive the wait, but now you will get a lot more continuous questions with every opportunity about the new printers etc.

In the meantime I hope someone can give me an indication of what would be needed to be ready for Prusa Connect when it becomes available. Will it be using a Raspberry Pi for connectivity or what can we expect. If that is the case then I can start working towards installing my Pi sometime rather than just keeping it on the shelf as a future project when I have more time.

By the way I can just add that I really like this feedback and the strategic approach that you are following to progress towards even more future success. To name just two points that illustrates this quite well, the point of bringing the injection molding into the process as well as your own PCB manufacturing (and obviously prototyping. I think that makes a lot of sense and can just enhance the progress so much. Not to mention the effect of 3D printing waste collection and transformation back into 3D printers; you just have to love that part.

Official Prusa Technician, count me it!

Great work you guys are the best hope that maybe you’ll consider in the next update of the mk3s to change the board and by doing so we could maybe get a color touch screen Although the textile button scroller fell great

That’s just brilliant. And what an inspiration it is to be part of the Prusa community.

Congratulations to everyone working for making everything better everyday!

Thank you!

Exceptional year for an exceptional company.

Wow what a crazy and productive year, really bummed it sounds like another year for the XL but such is life. Love prusaprinters.com and prusa slicer by the way, I try to get makers to move from that other site all the time as it’s prusaprinters is actually responsive and always improving.

Flash file is used to upgrade or reinstall the operating system in your device. It resolves different issues like application stopped working, Boot loop issue, dead issues and IMEI issues.

https://firmwareflashfiles.com/jio-f220b-flash-download/

Have loved getting my new Prusa printer late last year. The quality of the machine is very high but the customer support is second to none. My major concern however is the restrictions for UK customers arising from Brexit. The technicians idea is great and I hope that there will opportunities in the UK. It would be great if there was an authorised distributor based in UK too. Thanks for the great work and wish you continued success in 2021.

Prusa Connect ? Did not hear this before. I thought the cooperation with Octoprint was going fine? Would love to hear more.

Prusa Technicians? Oh yes! Tell us more ! Very interested after building 2printers and numerous upgrades

I love reading this. So many great ideas and out-of – the – box thinking like the barber shop and test center. Shows how much you care!

Official Prusa Technicians – count me in, where is there more info about it?!

Keep up your phantastic work!

I’d like to know when the Prusa Mini+ upgrade kit will be back in stock. And also when Prusa plan to start selling back into the UK again?

Dear Joseph,

Next to reading about Prusa-internal strategic plans (such as vertical integration), we as printer users are focussed to understand and impact the product development roadmaps, driven by customer needs.

One obvious one we all have been waiting for a long time is PrusaConnect: the right way to go!

Herewith I’d like to propose another customer need: a dual extruder printer or option to the current range, so that we can finaly print professional level parts without the frustrations of having to deal with the multi material option which is NOT doing the job. Look at the (frustration) forum of the multi material option and you will have to conclude that users don’t necessarily need a multi color printer, but a REAL multi-material printer capable of handling ONLY 2 materials: the print material and the support material. Not so difficult, Prusa can do certainly do that if it wants!

Offer a dual extruder and you will attract a large part of the market of more professionally oriented printers/makers/users.

Best regards and success!

Paul Matthijs

A beautiful, bright future awaits each of us. In everything

the effect of an unpredictable disease on COVID has spread around the world. For a whole year, we have been living in a difficult period. Together, we adhere to the anti-epidemic measures implemented in relation to the territorial distribution of the disease. The conditions of our company took into account all possible options and without complications, we switched to remote operation. Therefore, to please our students with articles with https://best-writing-service.net/buy-movie-review-help.html so necessary for their development and obtaining a positive assessment and support during the study period is always ready.

I also am extremely interested in the technician training!!

Really very happy to say,your post is very interesting to read.

Its pretty much same as https://apksdesk.com/windscribe-mod-apk/

yes you are right Its pretty much same as https://multimodapk.com/clash-of-clans-mod-apk/

Really very happy to say,your post is very interesting to read. https://apkengineer.com/naruto-blazing-mod-apk/

Because everyone has a different level of knowledge understanding, there will be a certain gap in the ability to receive knowledge. This phenomenon is most obvious in the comprehensive English ability. Online English training https://liulingo.com/ has been exposed to many in English Students who have learned grammar and vocabulary very well, but their oral and listening skills are relatively weak. Then, how should the comprehensive English ability be improved?

It is not enough to improve the comprehensive English ability by your own efforts. Many students have improved their comprehensive English level through online English training, especially in speaking and listening. Online English training provides systematic English comprehensive ability improvement courses. The course system is complete and equipped with experienced and high-quality European and American foreign teachers. Both in pronunciation and comprehensive teaching ability, European and American foreign teachers in online English training have a strong comprehensive Strength, choosing us is choosing success.

Thank You for sharing the information!

Netboom MOD APK is an application that will allow you to make sure that you can play PC games. The players can play for free on your mobile phone then Netboom is definitely the application for you. It allows you to play high-end PC applications and games. It makes sure that you get the best features so that mobile gaming can be possible for you. This software is based on cloud-computing technology.

It is possible to play huge computer games on your phone. This application will take care of the large applications that use up your computer’s RAM. With the cloud-based app, you can ensure that your device runs at its best.

For More, Visit Here: https://dapks.com/netboom-mod-apk-2/

Amazing Information!! Thanks

This is awesome I just started learning pattern design through internet resources and found this beautiful article thanks for this useful information.

For more information visit here: https://pragueeventery.com/

I completely agree with you, a very detailed tutorial https://wordcounter.tools

i read whole article that was providing me such a great information here: https://apkrevise.com/inshot-pro-mod-apk/ Thank!

yo whatsappapk allows you to hide blue tick, double tick, and online status, check https://thegbapp.com/yowhatsapp-apk/

Cute Thigh High Socks we give you Cute Thigh High Socks in discount so check here https://thighhighsocks.shop/collections/cute-thigh-high-socks

If it has been a long time you have not focused on your body, then you should give a little attention to adorning it.https://officialbellybuttonrings.com/

Halloween is one of the most cheerfully celebrated occasions. https://michaelmyerscostume.com/

Get All Android APKs https://apkshut.com/

Nice work!

What are your plans for winter 2022? If not created yet, here is an advice to go for a party ride or bus. Book any charter bus and go for a long tour. You’ll be amazed.

Good news. Very interesting article.

i must say that it is one of the best and informative post just like affordable SEO services

what you get from this post?

i appreciated your efforts that you put on this article. really hard word and must visit buy google reviews

i find this post really informative for me and I was just searching for this kind of information.

power wheelchair

Hey, what about this site www.arlingtonweddingphotographers.com? It’s also explaining the same topic as you explained.

hi all