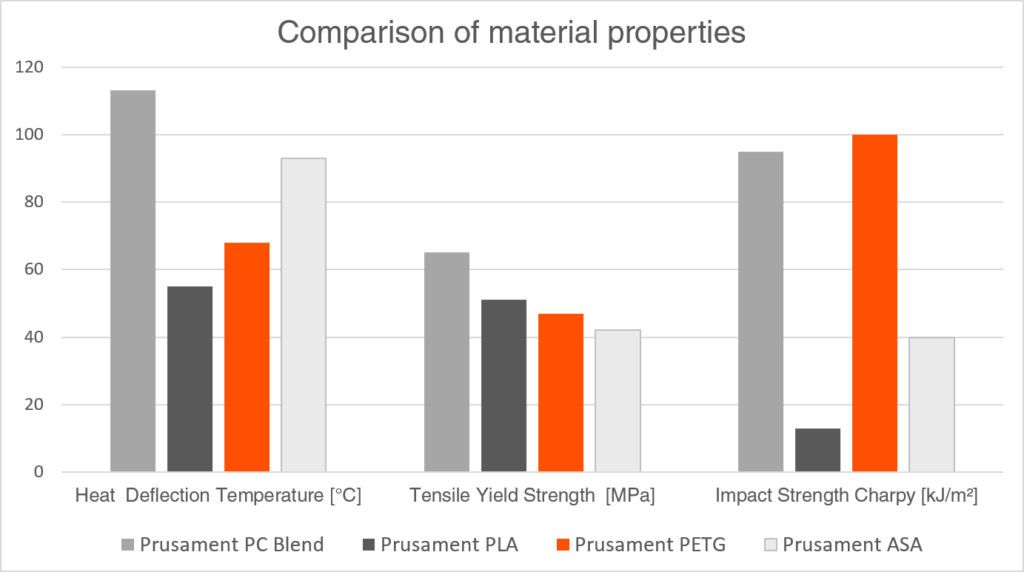

We are excited to announce that the lineup of our in-house produced filaments – the Prusament – has been expanded with a new material! Besides the well-known PLA, PETG, and ASA, we now also offer a new material called PC Blend (PolyCarbonate). PC Blend is perfect for stronger, more durable 3D prints.

Polycarbonates are a group of plastics that are known for their strength, mechanical durability, toughness, and temperature resistance. They are commonly used for the production of CDs, protective goggles and car headlights.

The composition of pure polycarbonate is not especially suitable for 3D printing. It adheres very poorly to the print sheet and due to its high thermal expansion, it has a tendency to deform and crack. This is why we put a lot of effort into the development of the new product. We have introduced carefully-picked additives into the mix, improving the adhesion and reducing cracking and warping, while still maintaining the excellent properties of polycarbonate. The result is our new Prusament PC Blend.

PolyCarbonate Blend specifics

Before we dig deeper into the properties of Prusament PC Blend, we should point out that this material is particularly suitable for advanced users. If you are new to 3D printing, you should definitely stick to PLA. PC Blend is recommended for experienced 3D printer owners looking for tough, durable material for production of prototypes and functional parts and thermally and mechanically stressed components.

| Pros | |

|---|---|

|

High-temperature resistance up to 113 °C /235 °F (for comparison, PLA begins to deform at temperatures around 55 °C / 131 °F ) |

|

Excellent mechanical resistance – very strong and rigid material |

|

Impact-resistant |

|

Tough and flexible even at low temperatures |

|

Very good dimensional stability compared to other PCs printed on a 3D printer without an enclosure |

|

Good resistance to creep (cold flow) under mechanical stress |

|

Does not contain styrene |

|

Good adhesion to the print sheet |

|

Improved printing properties compared to conventional polycarbonates – less warping during printing, cracks in layers are very rare |

|

Does not need to be dried before printing (it is very little hygroscopic) |

|

Good electrical insulating properties |

| Cons | |

|---|---|

| Prone to warping when printing large models | |

| Requires high temperatures on the nozzle and heatbed | |

| Higher price | |

| Produces a noticeable odor during printing | |

| Requires a separating agent (e.g. a glue stick layer on the print sheet) | |

Available colors and price

PC Blend is a material suitable for the production of prototypes and mechanical parts – this is why its visual side isn’t as important as, for example, with PLA. This is why we’re offering a smaller selection of colors: black (Jet Black), grey (Urban Grey) and natural white (Natural). All Prusament materials are made with extreme precision and above-industry standards (diameter tolerance of +- 0,03 mm) and all spools are perfectly wound. PC Blend is available on standard 1kg spools for 49.99 USD/EUR (VAT incl.).

Print sheet preparation

Prusament PC Blend can be printed on both smooth and textured print sheets. However, spreading a separating agent on the sheet before you start printing is required. Otherwise, the adhesion of the print may be too strong. The easiest way to prepare your print sheet is to apply a thin layer of paper glue onto the sheet. This is why we include a paper glue stick (KORES) with every PC Blend spool, free of charge. Failing to add a separating layer may lead to damage to your print sheet! While our documentation states that it’s not necessary to apply glue to the powder-coated textured print sheet, the PC Blend is an exception. Do not use the glue when printing with other materials (PLA, PETG, ASA, Flex and others)!

After you finish printing and remove the object from the print sheet, use isopropyl alcohol to clean the print sheet thoroughly! Avoid cleaning the textured sheet with water – this may lead to corrosion.

Suitable 3D printers

Compared to other PolyCarbonate filaments, our Prusament PC Blend is relatively easy to work with and the pre-print preparations are still quite simple. The recommended temperatures for nozzle and heatbed are 275 ± 10 °C (527 ±18 °F) and 110 ± 10 °C (230 ±18 °F) respectively. This means that all of our printers, Original Prusa i3 MK2/S, Original Prusa i3 MK3/S and even the Original Prusa MINI, can print with PC Blend. The MK3/S is the best option for printing large objects because the recommended heatbed temperature for larger models is 115 °C (239 °F). Smaller objects can be printed at 100 °C (212 °F), which is within the working range of the MINI.

The material is not abrasive, which puts it in the same league with PLA and PETG. This means that the standard brass nozzle (which is used by a majority of FFF/FDM 3D printers) is perfectly suitable.

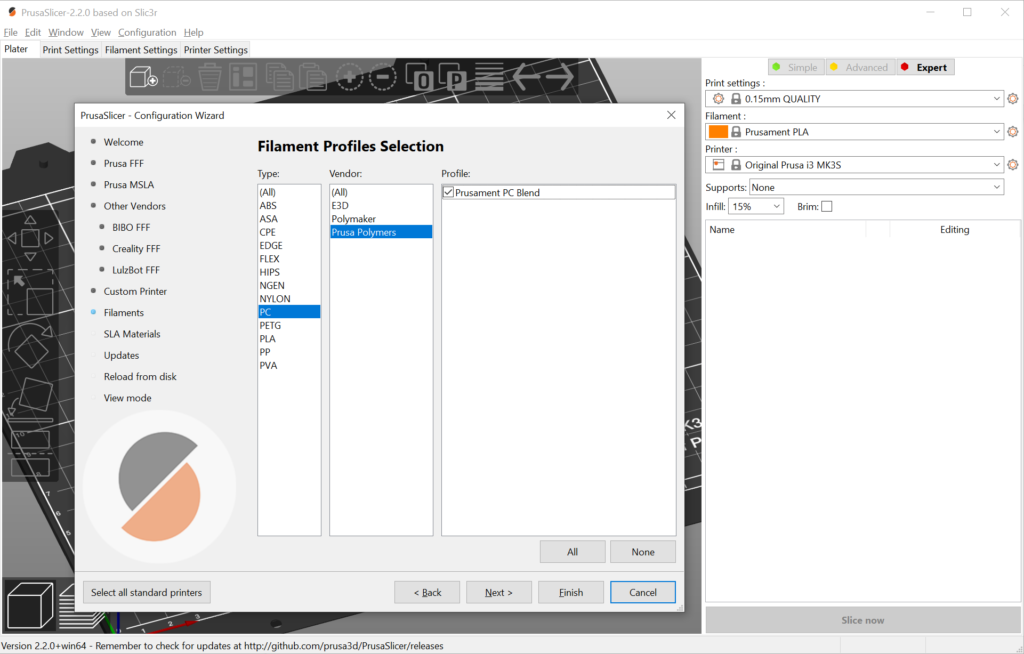

Protip: Do you need to add the Prusament PC Blend print profile into PrusaSlicer? Make sure you’re running PrusaSlicer 2.2.0 or newer. Go to Configuration – Configuration Wizard – Filaments – PC – check the Prusament PC Blend option and press Finish. Now, PC Blend will be available in the list of materials.

Tips and tricks for successful prints

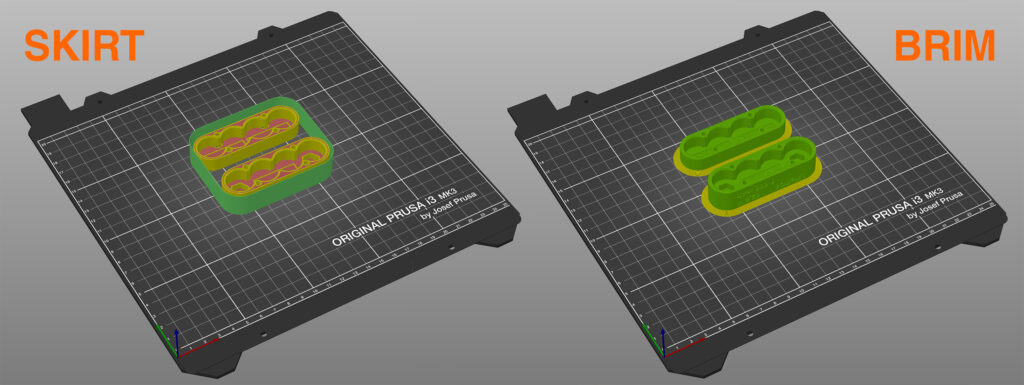

We recommend placing the objects into the center of the print sheet to achieve a good adhesion thanks to even heat distribution. A useful addition is the skirt, a thin wall around the object. It creates a microclimate around the printed object and blocks air circulation. In case you decide to print something smaller, consider using the Brim option. It adds extra material around the printed object, increasing the adhesion.

Generally speaking, PC Blend is not the best material for printing huge models stretched across the entire heatbed. However, it also depends on the shape of the object – circular models are easier to print compared to shapes with many sharp edges and angles. The tendency to warp is also affected by the infill and number of perimeters. With denser infills and generally more material inside the object, the higher the risk of warping – this causes the object to detach from the print sheet. If you print something large, you can consider lowering the number of perimeters (if it doesn’t affect the desired result).

In some cases, you may run into a “Bed thermal runaway” error. This usually happens when the 3D printer can’t maintain the high heatbed temperature. The cause is usually a combination of low ambient temperatures below 18 °C, a draft and a print fan set to 20% speed.

How to reduce model deformation when printing from PC Blend (summary in points):

- Increase the temperature of the heatbed

- Add a brim (width at least 4 mm)

- Add a circular skirt around the model (as high as the model)

- Reduce the number of perimeters and reduce the amount of infill

- Place the model in the center of the pad

- Print smaller objects

- Place the printer in a temperature-stable environment (no cold drafts etc.)

- Avoid printing in a cold environment

- Place the printer into an enclosure

Typical applications for PC Blend

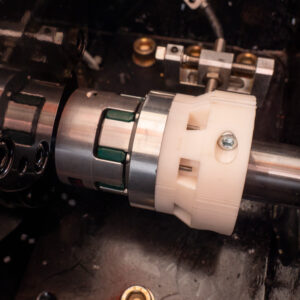

|

|

| Fan shroud (High temperature resistance) |

Battery pack (High temperature resistance, Good electrical insulating properties ) |

|

|

| Hinge (High mechanical resistance) |

Water angle valve lever (High mechanical resistance) |

|

|

| Granulation line (High mechanical resistance and good resistance to creep) |

Pulley linear bearing (Mechanical stressed parts) |

Happy printing!

Polycarbonate dissolves in chloroform and dichloromethane.

Can they be used to solvent weld PC Blend?

Good question. It would depend on what other compounds are “blended” with the polycarbonate.

The price is pretty competitive with other PC blends in the market. If it performs like other Prusament filament products, it will find its place in many maker shops. I do not know what the market price is for the raw PC materials, but if Prusa’s PC Blend becomes cheaper I will be using it for most parts I design. I’m likely, however, to at least keep one spool in my stock for specific designs.

500g spools would be nice to see in future.

1Kg is a bit too much for a technical material that you don’t use much. I won’t be able to use 1Kg. I don’t want to pollute. 500g would be enough.

I can not find a PC Blend option for first layer calibration. I have used the ASA option successfully for now. Also, I could not find a PC Blend preheat option on the control panel so I also used the ASA option.

“Protip: Do you need to add the Prusament PC Blend print profile into PrusaSlicer? Make sure you’re running PrusaSlicer 2.2.0 or newer. Go to Configuration – Configuration Wizard – Filaments – PC – check the Prusament PC Blend option and press Finish. Now, PC Blend will be available in the list of materials.”

I can not find a PC Blend option for first layer calibration. I have used the ASA option successfully for now. Also, I could not find a PC Blend preheat option on the control panel so I also used the ASA option.

This PC Blend Material prints excellent

“Protip: Do you need to add the Prusament PC Blend print profile into PrusaSlicer? Make sure you’re running PrusaSlicer 2.2.0 or newer. Go to Configuration – Configuration Wizard – Filaments – PC – check the Prusament PC Blend option and press Finish. Now, PC Blend will be available in the list of materials.”

Hi guys, I’ve looking for the Prusament PC Blend print profile, I can’t find it. In the Configuration Wizard>Filaments>Vendor>Prusa Polymers, there are just three options ASA, PETG, PLA. The version I’m running is PrusaSlicer 2.2.0+win64.

I know that I can create a custom profile (I’m doing it right now), but I was just curious why isn’t showing up?

Just downloaded PrusaSlicer 2.2 for win64 and also cannot find the Prusa PC Blend filament profile.

“Protip: Do you need to add the Prusament PC Blend print profile into PrusaSlicer? Make sure you’re running PrusaSlicer 2.2.0 or newer. Go to Configuration – Configuration Wizard – Filaments – PC – check the Prusament PC Blend option and press Finish. Now, PC Blend will be available in the list of materials.”

What’s the printed model used in the pictures with the spools? Looks like it says PRUSA on it, but I can’t find it in the uploaded prints of the Prusa account on PrusaPrinters Prints…

A parameter not often given : the resistance of the material to the UV?

I have just downloaded the latest Prusa slicer for windows…there is no Prusa PC blend option at all

The only options under PC are for E3D or Polymaker

I do not have any experience with PC Blend, so I am wondering how does it do with details, overhangs and bridging?

Interesting information

How is the UV-resistance of the Prusa PC Blend?

It it suited for outdoor use?

I found the pc blend in the new Prusa Slicer under Configuration, in the top menu, then Configuration Assistant, then select filament on the left, then PC in the Type column, and then you will see 3 options in the profile column on the far right and select Prusament PC Blends from there! Hope this helps those that can’t find the profile.

Cheers

Jeff

Thanks for sharing this post with us! The 3D printer is becoming more and more popular among the people who would like to get connected with the following things. The flirtymania has been providing some great ways to get connected with the other people around the word.

Just printed several items with PC Blend on my MK3S. Parts were small, 30mm footprint.

Used glue stick, as I do with Bridge & 910 Nylon. No problems, no smell and no brim required. I just re-sliced existing STL files.

For more details please follow me at my blog

I would like the article to mention what material is best to use when soluble supports are needed for a model. The issue is nozzle temp, which is much higher for PC Blend, so regular soluble filaments like PVA should not be used. Prusa support suggested ASA, Marvl3D have a high temp soluble material, but its very expensive. ASA is half the price of PC Blend, but the solvent isn’t water, its acetone.

Any further ideas.?