Update info (15th March 2023): We have updated the article with some additional information:

- The paragraph about gifts has been updated – we decided to add gifts to all preorders, not only to day-one preorders.

- FAQs were updated with questions regarding reviews, upgrades, and printing speed.

- We have added more info about input shaper for readers who haven’t heard about this feature yet.

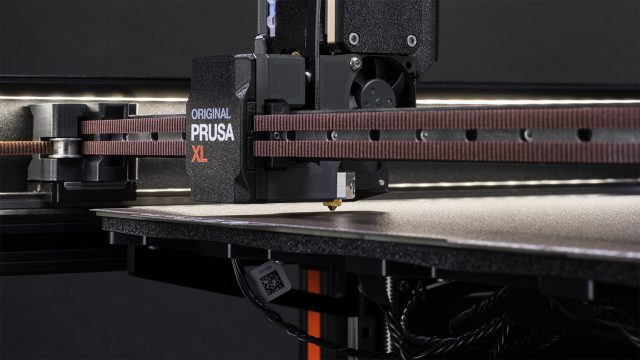

Finally, the first production units of the Original Prusa XL are ready to leave the company and head to their new owners! Today, we sent the first batch of e-mails with instructions on how to switch XL preorders to regular orders (see FAQ below for more details). Right now, we can fulfill only the orders from the first few minutes of the pre-sale, because the interest in the XL was crazy. The first shipped batches will be smaller, but we’ll gradually ramp up the production. We will need several months to ship the thousands of Day-1 orders. I also have news about the software and hardware changes, shipping info, and more, so let’s jump right in.

Single-tool XLs are on the way with two gifts!

The first units leaving the factory are the assembled single-tool XLs. As for the multi-tool machines, we’re planning to send the beta testing units to our external testers in about two weeks. We will run an external beta test for a month and then take about one month to incorporate all the feedback. The first multitool units are expected to be shipped in May 2023.

I’m not gonna deny that we didn’t manage to stick to our planned schedule. We’ve been running intensive testing since last September and ramped it all up in December when we sent a large batch of XL 3D printers to external beta testers, resulting in a lot of useful feedback and new tasks we wanted to tackle before shipping the printers to you. So it was incredibly busy during Xmas and while we thought everything was going to be wrapped in January, we needed a few extra weeks to ensure the changes were properly tested. It was pretty stressful but I think in hindsight, it was definitely worth it. Kudos to the entire team who managed to see the project through to the end!

We want to make it up to you guys for waiting longer than expected. All preorders (not just day-1) will receive two gifts: an extra print sheet (a double-sided textured sheet) so you can hot-swap it with the default satin sheet. Thanks to the Loadcell technology, you don’t have to tune Live Adjust Z for each sheet – it’s so convenient! The second gift is a Nextruder-to-V6 nozzle adapter. The XL uses a special nozzle with a metal filament guide (so no more PTFE tubes inside the extruder) and using this adapter, you can still mount any V6-compatible nozzle, including high-flow and hardened models.

Meanwhile, we were finishing plenty of other things – print profiles, firmware, PrusaSlicer, and Knowledge base articles… there’s a lot of work to be done with every 3D printer release and it’s much more than just hardware. And when we change one thing on the printer (e.g., based on the feedback from testing), it is often like dominoes – it affects print profiles, help articles, the handbook and so on.

Hardware changes

Speaking of feedback from testing, let’s talk a little bit about what has changed since December – it’s quite a lot of things, actually!

We improved the overall stability and firmness of the entire printer by using stiffer metal profiles and more robust printed parts. To be more specific about what we did:

- Replaced plastic handles with metal ones for increased robustness

- Adjusted the shroud for the print fan

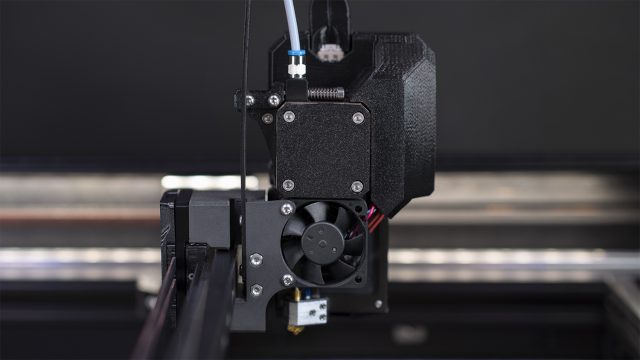

- Upgraded plastic parts of the Nextruder

- Adjusted the filament sensor to prevent jams

- Replaced X-axis profiles with stiffer ones and adjusted the size of the X/Y axis side panels to make more room for RGB LED strips

- Redesigned the mounting parts for the toolchanger to make future upgrades easier

- Improved several plastic parts (X/Y Axis)

…and more! These are not major changes but mostly small tweaks and quality-of-life improvements. I already covered some of these in a recent video blog, so check it out if you haven’t already. You can also compare the printer in the video with the photos of the final product and see how much has changed since we published it. 😉

Software changes and Input Shaper

Just to give you a little glimpse of what we changed software-wise in the past few months:

We have finished the redesign of the entire printer menu, which was based on the Original Prusa MINI. Now it is easier to navigate and there’s a new section called Control that groups together actions and tests that directly affect the movement or temperatures.

The Settings menu has been redesigned, too. It now features more advanced options (customizable UI, RGB status bar, special options for preheating) and also experimental features. But there were also a ton of changes under the hood – we’ll probably give you a proper look at the technology in a separate dev diary because there’s a lot to talk about.

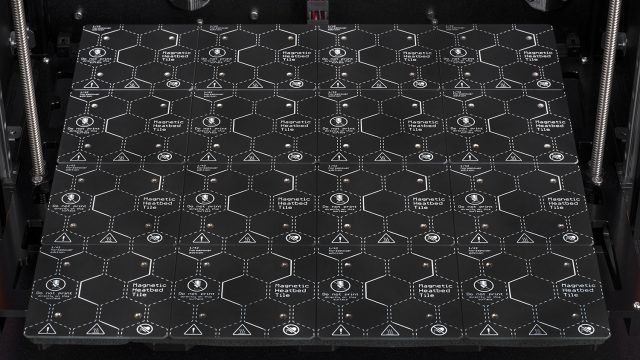

One of the most awesome features of the XL is the modular heatbed. We kept improving the firmware controlling the heating and the fully automatic first layer calibration (Mesh Bed Leveling) to make sure that no matter what material you choose, you’ll always get that perfectly smooth first layer.

Achieving this was more difficult than it sounds. Even though the heatbed tiles have expansion joints, the massive print sheet and the bed carriage still have a tendency to bend slightly as they heat up. For instance, if you place a small object in the middle of the heatbed and print it from polycarbonate, we could theoretically activate only the heatbed tile directly under the object. However, the temperature difference between heated and unheated tile would cause the print sheet to bulge out. This is why we also heat up the neighboring tiles slightly to lower the temperature difference. For this reason, PrusaSlicer automatically places printed objects in the front left corner to make it more energy efficient.

Differences in temperatures (heatbed vs carriage vs print sheet), heat dissipation, and transfer can also affect the initial Mesh Bed Levelling. We added an “Absorbing heat” function to MBL that waits until the heat from the heatbed is at least partially transferred to other parts, and only then the Nextruder performs the MBL procedure to achieve a perfect first layer.

And these are just a few things we added to make the overall experience in line with our other printers – make it super easy to set up and run and give you access to advanced stuff you can play around with.

I’m sure many of you are also waiting for another piece of important info: for the last several months, our devs have been working on Klipper-inspired Input shaper and Pressure Advance implementations. This is our own implementation for the STM32 bare metal, not a direct port of Marlin – Klipper has a more precisely implemented input shaper and pressure advance and that’s what we’re after. We’re not quite finished yet, but we hope to share some videos with you soon. 😉

As always, launching a product is not the finish line for us – we’re gonna keep improving the XL further and further, the same as what we do with all the rest of our machines.

With the XL, we’re also releasing PrusaSlicer 2.5.1 with factory-tested XL print profiles. I know that many of you are already using 2.6 alpha because of the awesome organic supports and other new features. We need a bit more time to finalize 2.6, but if you want, you can, of course, use it with the XL, too.

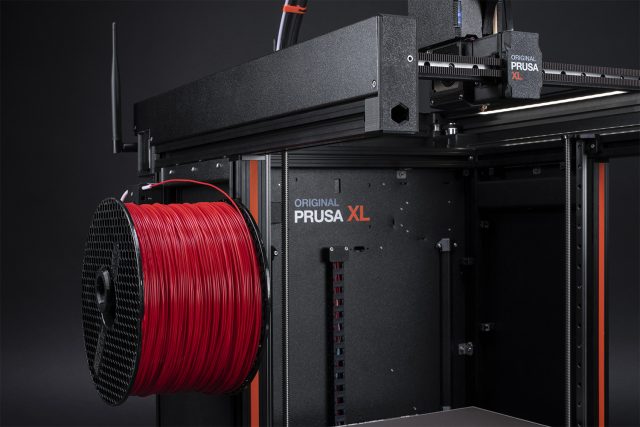

2kg Prusament and accessories

The XL can easily chew through an entire spool of filament in no time. With the filament sensors built-in, you don’t have to worry about failed prints. However, you need to keep in mind that you need to switch filament during the print.

This is why we are starting to offer 2kg spools of Prusament filament. We’re kicking it off with the most popular materials, but we will gradually expand the range. Right now, these are:

- Prusament PETG Jet Black 2kg

- Prusament PETG Prusa Orange 2kg

- Prusament PLA Prusa Galaxy Black 2kg

- Prusament PLA Lipstick Red 2kg

We’re also adding accessories for the XL to our eshop – most notably additional print sheets and nozzles with various diameters (from 0.25 to 0.8 mm) along with the V6-nozzle adapter that allows you to install any V6-compatible nozzle into the XL. We’ll also expand the offer of nozzles with new types soon (such as hardened variants for printing with abrasive materials). We’re also going to offer a combo of the nozzle along with the heater block, so you can literally swap nozzles in seconds.

Shipping information

In the first few minutes of launching the preorder, we received thousands of orders. With our current production capacity, it will take us several months to clear the backlog. We expect to ship less than a thousand units by May.

Here’s when you should expect to receive an e-mail from us: Once your printer is close to being shipped, we will email you in advance that your reservation is now ready to be turned into a final order. You can edit the shipping address (you can change the ZIP, but not the country), add more items to your order, and select the shipping method. You can’t increase the number of XLs, but you can decrease it. There is no deadline for converting the reservation into an order right now. The reservation date is decisive; as soon as you complete the payment, you will jump into the right place in the queue.

However, if you wish to upgrade to multiple toolheads, you have two options. You can finish the order of singletool printer right now and purchase additional toolheads as an upgrade later or you can wait until we start shipping multi-tool head printers. We will send you an e-mail reminder when they are ready.

After the shipment of multi-tool printers starts, you will be able to adjust the configuration of the XL: the number of toolheads and other parameters, such as choosing semi-assembled or fully assembled, etc. Please keep in mind that if you add more toolheads to your existing order, your order will take longer to process.

The semi-assembled version will start shipping in May 2023. The process of manufacturing a semi-assembled printer is different and requires a new set of testing machines – these could not be built until after we wrapped up the hardware on the final XL. We expect to have the testing machines ready by the end of April.

We’ll also publish an updated shipping table once the production is more stable.

So, that’s it for now. We’ll bring you more XL news soon!

Happy printing!

FAQ:

Q: What nozzle is pre-installed on the XL?

A: A 0.6mm nozzle – it offers a great quality/speed ratio, allowing you to print large objects faster. With the Arachne mode in PrusaSlicer, the quality of the print is actually similar to 0.4mm nozzles.

Q: What other nozzle sizes will be available? What about compatibility?

A: We will offer all usual nozzle sizes (0.25mm – 0.8mm) and we’ll have a Nextruder-to-V6-nozzle adapter available on our e-shop. Hardened and high-flow nozzles are coming later, but you can mount any compatible V6-type nozzle with the adapter.

Q: What is the default steel sheet option for the XL?

A: The default option is the satin sheet.

Q: Is the draft shield included with the printer?

A: The shield is not included by default; it’s an upcoming optional accessory. The price will be specified later.

Q: Will there be an enclosure for the XL?

A: The enclosure will be made available later this year; right now, we want to focus on the production of the XL. We will publish more info about the enclosure later on.

Q: What is the PSU configuration of the XL, and how does it change depending on the number of toolheads?

A: The XL has two built-in PSUs by default (for the single-tool version). The two-PSU configuration is enough to run up to two toolheads. If you want three and more toolheads, it is necessary to install an additional PSU due to power requirements. Of course, we supply the printer with EU/US/UK plugs depending on the country of destination.

Q: Can I upgrade from a single-tool XL to a multi-tool? Can I do it gradually (e.g., purchase one extruder and later another extruder?)

A: Yes, we will offer upgrade kits later after we start shipping the multi-tool version.

Q: What are the plans for Klipper / Pressure Advance / Input shaper?

A: We’re preparing and testing our own Klipper-inspired Input shaper and Pressure Advance. This is our own implementation for the STM32 bare metal, not a direct port of Marlin – Klipper has a more precisely implemented input shaper and pressure advance.

Q: What is Input Shaper and Pressure Advance?

A: Input shaping is a technology used for resonance compensation. As the printer moves and changes directions quickly, these movements can translate into artifacts on the printed objects called ghosting. With input shaping, the printer can effectively eliminate or minimize these artifacts, resulting in cleaner, nice prints. Pressure Advance is a technology that calculates how exactly should be molten filament pushed out of the nozzle. It follows a formula to boost the velocity of the extruder at the start of a line and reduce it at the end, plus it looks ahead for corners and makes other adjustments to ensure a smooth and consistent travel. Input shaping combined with Pressure Advance allow for noticeably higher printing speeds.

Q: When will you publish printing speeds for the XL?

A: Once we have Input Shaper and Pressure Advance up and running. We need a bit more time to finalize everything, but publishing current printing speed values would not fully reflect what the XL is capable of. We’ll have numbers for you soon!

Q: Does the XL extruder have an accelerometer built in?

A: Yes, it does – it’s vital for correct Input Shaper configuration (see above).

Q: When I decide to upgrade the XL gradually (start with a single-tool version and later add more extuders), will it be more expensive than buying a standard five-toolhead XL?

A: There will be single toolheads available for purchase, but we will also prepare upgrade kits that will minimize the price difference.

Q: When can we expect reviews?

A: Our production capacity is extremely limited at this point. We want to prioritize our customers, so review units will be available later along with the multitool version of the printer.

Orders / Shipping FAQ:

Q: Will it be possible to change the number of printers in my order?

A: It is possible to decrease the number of ordered units, not increase it

Q: When will shipping estimates be available?

A: In the upcoming weeks, once the production stabilizes

Q: When will the email confirming my preorder be sent?

A: Email calls asking you to complete the payment will be sent once your XL is getting ready to be shipped. You still have your place in the line, so even if you don’t complete the order immediately, you will jump into the correct position in the queue once you do.

Q: Will there be a cheaper shipping option when ordering from Printed Solid?

A: We want to make it possible in the future, but with the current production capacity, it is not possible at the moment.

Several months to process day 1 orders. How’s the chance to get january orders by the end of the year? That’s really disappointing!

They might have quite a few canceled preorders given the delays and the Bambu X1C. I really want multiple tools and an enclosure and I won’t have either until at least May. I’ll hang onto my order for now but I’m only committing if feedback on the single tool version is really good.

That and on top of changing economic times, a lot of people won’t have extra money to spend on the XL. I think many people will change their mind when it comes to putting in the final payment.

Yes they must think the tax problems as well. and changing the country how is not possible. is that they told if I transfer to work or fixed living to another country(with this how I am not possible not to change the shipping country? is that 2 years gap)PRUSA said me to go to your previous country by aero plane or ship and collect it with stay which I put address until product coming to me? its hilarious. no place if i sold my address if i do not have person to keep it ,How did I waste that much money?

actually who orders to think like this for prusa?

They want to stop people from selling early spots in the queue to the highest bidder. That’s why you can’t change the address directly.

I am fairly sure that they will find a solution for people that ask their support nicely instead of just complaining.

People who’ve cancelled are already out of the queue. But I’m pretty sure a lot of people hang on to their orders to see if the XL delivers on the promise. I want the 5 toolhead too. Thought about going for the 1 or 2 head first, but the delay gives me more time to see if the XL is really good or had a lot of problems. I do hope that all the extra time it took to delevelop the machine means that they’ll really deliver a machine without too much teething problems. You can expect a few problems, but let’s pray together (for the good it will do…) that these can be easily fixed with firmware updates or printed parts.

And when the XL is finally there, I hope that the people that keep comparing it to the Bambu will see that these are two different machines. The Bamu is a great machine in it’s own right, don’t get me wrong. Bambu Labs did a good job of disrupting the industry and make a machine that could have been a Prusa. But while it is similar to the XL in terms of capabilities, they are different in design and how the capabilities are achieved. For instance: for the first layer, the Bambu relies on the Lidar gizmo, while the XL uses advanced sensors in the nozzle/print head to determine the flow and proximity to the build plate. But the XL keeps using the sensors to regulate the flow during the print too. So in theory, Prusa’s solution looks more advanced. However, the prints that the Bambu spits out look great too, so the advantage might be less important. We’ll see how it all works out. The main thing for me is the multiple toolheads and the speed advantage that they bring for colour changes, and also less waste. On the other hand, the Bambu can use a couple of AMS units and the XL will be fixed to 5 heads.

The Bambu also has less print volume. (256mm cubed.)

One difference I noticed is their emphasis on active vibration compensation. How about designing your frame so that it doesn’t vibrate as much in the first place? Or smoothing your acceleration profile?

Also, sorry but I’m not going to feed China with even more of my money if I can help it. And not to a company whose website doesn’t even show their physical address. Or an EU contact. Nice try.

Ryanlp>>I’ll hang onto my order for now but I’m only committing if feedback on the single tool version is really good. <<

I hear you buddy! I preordered the 5-extruder version in the first 2 hours they opened preorders. But the entire 3D printer landscape has changed since then. And with some of the backtracking on the XL (like loss of the cycloidal drive) has made the value proposition on this printer potentially more questionable. At $3500 this printer will have to be an all out home-run for me to commit to the order.

I really hope they score that hit. I'm in the stands cheering for them – as I really prefer to remain in the Prusa camp. But when we see the value proposition some other vendors (like Bambu) offer – it's fair to say it will be challenging.

The Prusa eShop currently says on the XL pre-order page: “New orders will be processed in the Q4 2023”. So… I’m thinking a January 2022 preorder will be processed before that. =)

Not day 1 orders. Day 1 PRE-ORDERS. Not disappointing at all for anyone with a single clue.

That’s some good news! I’m not sure of remembering the launch date of the XL. I did order it on November 18th 2021, will I be receiving the day1 gifts? 🙂

I really hope so because that’s the same day I pre-ordered 🙂

Yes, looks as if it was November 18 2021. https://blog.prusa3d.com/original-prusa-xl-first-look_58312/

From the wording of the article it seems like 3 PSUs will be required for more than 2 toolheads. Does this mean 3 PSUs will cover up to 5? Or does it scale and since 2 PSUs can do 2 tool heads you’ll need 5 PSUs for 5 tool heads?

3 PSUs can handle all 5 toolheads from what they’ve shown previously.

Yes. The bed is probably what takes the most power. So adding another PSU will be enough for the toolheads.

The calibration wizard is super easy, barely an inconvenience. Wow wow wow wow wow.

Super easy calibration wizards are tight!

The year is 2023, let’s check in with our time traveling reporter from 2035 to get an update on the Prusa XL release.

Only day-1 orders will get two gifts? What is with 2nd day orders or 1week orders?! They have to wait quite a while longer for the XL and won’t get a gift. I think that’s too many setbacks. Please treat us equally!

Which was Day1 for the XL?

November 18 2021. https://blog.prusa3d.com/original-prusa-xl-first-look_58312/

I ordered mine on the 19th… I definitely feel that anybody who ordered within the first week needs those gifts. Especially those who ordered a 5 tool head model.

A bottle of whisky would be more like it.

Counter point, the folks on the first wave of orders being shipped are still taking the most risk; they’re spending $2k or more on a machine that hasn’t yet been reviewed by the public. Their machines are also likely to have the most flaws and issues as Prusa is ironing out the kinks.

The waiting stinks, sure, but with every wave that ships the product stabilizes and the reviews (good or bad) start to come in, and the person whos number is called 6 months from now has the benefit of 6 months of user feedback to inform a decision to commit or get their deposit refunded.

Good point.

You are absolutely correct.

The link to the Youtube video about the XL update is broken (extra https:// and missing : on the second one.

I have a day-1 pre-order for a multi-extruder model, but I no longer have a need for the the tool changer. Where will I end up in the queue for fulfilling my pre-order? will I have the option to get my printer sooner if I down-grade to a single-extruder? Based on the wording, it seems like people who pre-ordered single tool-head versions can wait two+ months and upgrade their order, but not the other way around.

You shouldn’t downgrade if it’s not because of the money. The text says „several months for Day 1 orders“. You‘ve never been in that queue. Just imagine, If you‘re able to downgrade, they will definitely put you at the end of the single-toolhead queue, which means „several months for day 1 + everything what came after. The doors are not open yet but you‘ll be much, much faster if you stay at your position in the current queue.

Will I receive 5 Adapters as a gift if I’ve ordered 5 toolheads? 😊

I ordered at 11.17pm GMT on 18th November 2021.

Does that count as a day one order? Is it day one order to the buyers time zone or your time zone?

I sure hope so! I had to wait until after work on Nov. 18th to order, so, something like 6pm EST in the US.

Seriously. What’s wrong with writing sentences without making every few ones in bold? It’s so irritating as someone with dyslexia to read these articles. It’s as crazy AS USING CAPITALS TO SHOUT AT PEOPLE. So STOP. Just writing articles without applying bold to sentences. It’s amateurish, distracting and makes it harder to read.

Makes it more readable for me and easier to find information later on.

That’s not standard English, it’s an ugly hack. What you’re asking for is a bullet point list. That’s what it’s for. Bolding phrases and sentences like that is nuts, sloppy and bad. Summaries and bullet list exist for a reason. Go bold stuff like that on a research paper (which is “serious” English) and see what happens to it. It will be refused. I haven’t seen this type of writing even by Elementary School students.

Their English is much better than my Czech, probably your too. The bolder first sentence of each paragraph highlights the topic. It is accepted form of technical writing but not literary English.

Back on topic—really excited for the XL—gonna pick up a mini and start with that but hope to move up to an XL for bigger cosplay parts.

I agree.

I would say too late too little..

And the price is just ridiculous high for a profiles and printed parts printer.

For everyone who is interested…, most here are i guess. I designed the PRUSA XL in FUSION in ORIGINAL SIZE.

You can download it on printables( use Link or go on my Profile) :

https://www.printables.com/model/423459-prusa-xl-original-size

Great! Thank you!

When can we expect first reviews? Did the reviewers already receive the printers?

For those of us who made a preorder on day one and have since made an international move, are we just out of luck?

I was counting on the ability to change address, but now we are learning that we can’t change countries. Does this mean I have no chance for an XL for a couple more years as I will have to put in a new order?

The Prusa eShop currently says on the XL pre-order page: “New orders will be processed in the Q4 2023”. So… I’m thinking yours will be processed before that. =)

its hilarious.

I also have same issue man. country situation. I do not know why they do not allow to change the country

Maybe because people could then sell their pre-order to others and pretend they moved since ordering. I’m just guessing, but I assume Prusa will be busy until the end of 2023 with fulfillment of the pre-orders, so new orders won’t be served until 2024. It may be lucrative to sell your pre order.

Haha I tried but nobody wanted them…I just canceled my orders after I lost confidence in Prusa.

Great to hear that the XL is finally shipping.

I pre-ordered early on day one. Well, I thought so. I didn’t recognize that I entered the wrong CVC during payment and therefore the order was canceled because it was unpaid for too long 🤦♂️. Took seven month until I found out by accident (my day was ruined…). So I will have to wait for a long long time until I get one 😭.

I’m just excited to see the advancements this brings to Prusaslicer.

Can the filament sensors be relocated to the rear of the printer? Would like to feed my multihead printer ( its commin (: )from the rear, rather than the side mount. Narrower foot print suits my set up.

Re: “Differences in temperatures (heatbed vs carriage vs print sheet), heat dissipation, and transfer can also affect the initial Mesh Bed Levelling. We added an “Absorbing heat” function to MBL that waits until the heat from the heatbed is at least partially transferred to other parts, and only then the Nextruder performs the MBL procedure to achieve a perfect first layer.”

I’ve done similar things on my MK3. I used to wait for the PINDA to warm up to a couple degrees above the PINDA calibration range (I think the bottom of the range was 30°C so I would wait until it reached 32°C) which would also end up doing something similar to “Absorbing heat”. Ever since I upgraded to MK3+ with the Super PINDA (that doesn’t have an integrated temperature sensor), I’ve modified my custom start gcode to simply have a 5 minute delay to allow the bed surface to stop (or slow down) moving from thermal expansion of the bed, frame, etc. Note, the value of “5 minutes” wasn’t empirically determined. I just guessed that 5 minutes would be “long enough”. Anyone can do this just by adding a timed pause to their start gcode after the “wait for first layer bed temperature” code. To cut down on oozing in my start gcode, I have the nozzle at 160° while the bed is heating and during the timed pause. I only set the nozzle to the first layer nozzle temperature after the timed pause has completed.

Re: “We have finished the redesign of the entire printer menu, which was based on the Original Prusa MINI. Now it is easier to navigate and there’s a new section called Control that groups together actions and tests that directly affect the movement or temperatures.”

I wonder if any of this UI reorganization for easier navigation will be rolled back to the MINI UI (obviously with the features that the XL has but the MINI doesn’t removed).

The more I hear about the features of the nextruder, the more I hope that there are plans to use the nextruder in the MK4, and into the MK3 to MK4 upgrade kit. (Or similar to the MK2 upgrade path, a MK3.5 kit if the differences between MK3 and MK4 are large enough.)

What happened to the “official but unsupported” klipper support. Is that not happening now that you are doing input shaping? Will the printer support klipper?

How will remote printing work with wifi?

Hi, it is great news that the first printers are ready to go. Have you sent any to the usual, independent content creators? I’ve not checked every one for their independence, but it would be reassuring to see Teaching Tech, Denys Wang, 3Dprinting Nerd or any number of trusted reviewers, review the printer. I’m surprised that this hasn’t happened yet, before you ship the finished product. You’re asking your customers to take a whole lot on trust, and, somewhat, resting on your laurels. It is a bit presumptuous, if I may say. If I were the suspicious type, I’d be asking “what are you trying to hide”?

The best thing I did this year was cancel my Prusa XL orders and buy Bambu Lab P1Ps. What a shame for a company like Prusa to set delay after delay and be totally out of their mind with their dates. They knew from day 1 that this was never going to happen, even now when you have a week old order and want a multi toolhead enclosed the earliest you will be up and running is at start of 2024 😂 come on guys. And have you seen the printing speeds on the XL. You know I am laughing but from the inside I am crying.

This is a product even Prusa is already not proud of its covered with negative vibes already and it hasnt even come to market yet.

I am sorry to say this all but I get so sad when a company is dying because its own succes.

No samples for independent reviews. I can totally understand you prioritize customers but man that’s literary buying a XL pig in a poke.

Will the be any public information about the beta tests?

I hope there are some first order content creators out there 🙂

The fact there is still a lack of informations/proof about speed and quality makes me feel sad and disappointed. Although speed isn’t everything … at least it should compete with other (cheaper) solutions out there. Technical support and “it’s a prusa” aren’t the only selling points as well you know?!

I wonder how “the XL handles materials like PC, ABS,… with ease” turns out in the “out of the box” configuration without enclosure. If it can’t handle it in stock configuration your statement is definitely a lie. Only the fact it can melt the plastics doesn’t mean it can print it … so my BBQ can handle these materials with ease as well…

Still hoping for the best 👌 Don’t let us down prusa.

Did I miss the prices?

Especially, what will be the difference between the XL-single and the XL-5multi head models? And what would be the price of the 1-to-5 upgrade?

It would be nice to know the specifications of those multiple PSUs. It implies a lot of power usage, and If they use too much i will have to cancel my preorder.

Delays are to be expected with something cutting edge and I, for one, appreciate that Prusa will not ship units until they are satisfied. I’d rather wait another 6 months than have something that doesn’t quite work or breaks down or is just junky.

Keep the bar high and keep up the good work!

Anybody got Prusa XL already? First experience notes? 😉

https://www.reddit.com/r/prusa3d/comments/125t2bw/my_xl_has_finally_arrived/

Nextruder-to-V6 adapters not available in shop :/ (at moment of writing). When they will be available?

If you want to see a first production machine in the wild, check out the unboxing done by Practical Printing on 29 MARCH 23 on youtube. Video title is “Original Prusa XL – What to Expect When You’re Expecting…”

Also a lady at TADA 3D printing has posted a few videos of her Production release Prusa XL to youtube too.

Prusa XL is here! First look after unboxing

Printing “Buddy the Prusa Pug on the Prusa XL!

Printing a Speed Benchy….

etc.

At time of writing the Lady has 348 subs – Yesterday she had 281 so perhaps she is getting some traction form a couple of comments i’ve thrown around and youtube promoting her.. Show her some love…

How is it that there is no one else reporting and posting about the XL? But hundreds habe their MK4 , which was shipped later. Did Prusa send out 1 , to post that they began shipping, but then stopped? I find it highly unlikely that they are really shipping them…

Where did the RGB LED bars inside the printer go?

Oh Prusa, please send me my multi-tool XL! If you really plan to delay the shipping again, could you at least be kind enough to give us an update beyond this one from 2 months ago? I would be happier hearing transparent things like: the mulit-tool XL has a problem and our engineers don’t know how long it will take to fix, or we had a problem packaging the kit and this looks like something that needs an extra couple months, or sourcing some component is currently our bottleneck, and we are waiting to hear back about that… SOMETHING. Please?

I also really hoped, that they would do a Livestream yesterday. I mean im waiting now for 2,5 years. Is it really a problem to release information about, In Time, or delayed because ob XYZ.

It seems incongruous to not have a full enclosure for the XL. I know that initially you were showing a pull up “bellows” that was to be available at the time of finalizing your order, but I haven’t seen any mention of that lately, or of an optional enclosure to prevent warping of advanced materials. And the bellows was ingenious, but seemed to only be useful to shield the print from room drafts.

For those of you wondering what timeline is current for the XL 2 head and multi-tool versions, I was directed to this site from the Customer Service team, which has specific dates! Woo! https://help.prusa3d.com/article/shipping-information_2297

I would have liked to have seen 2 filament runout switches per hotend to prevent false stopages. I currently use this setup and if both switches say there’s no filament then and only then stop the printer. The switches are cheap and easy to implement.

Also I use 3kg spools and note that only 2kg are supported on the reel holder!

The last update was May 30th saying:

“The initial batch of dual tool printers is scheduled to be shipped during the week of June 19th. We are actively working on preparing these units for delivery and ensuring their quality meets our standards. The five-tool printers will follow approximately one month later.”

It’s been over 3 months of silence on this.. could we get another update?

Add another month to that, and the dates have shifted. All while linking to updates that have zero updates actually on it!

ok… let's say I booked in February 2022 and in October 2023 I still have nothing in hand. You should give the two gifts to everyone… not just the first printers to leave the factory.

I ask this because while you were working on the printer, in the meantime I built a house, had 2 children, married, divorced, married a second time, missionary in Rwanda, got drunk in Memphis, visited Patagonia, walked Beijing to Paris and pissed in the Niagara Falls