This story will bring us to ETH Zurich, Switzerland, one of the world’s leading universities. A place where developing innovative solutions, pushing forward new inventions, and performing ground-breaking research are part of the day-to-day business. A task that is only possible with the use of the right tools – such as an Original Prusa 3D printer. 😉

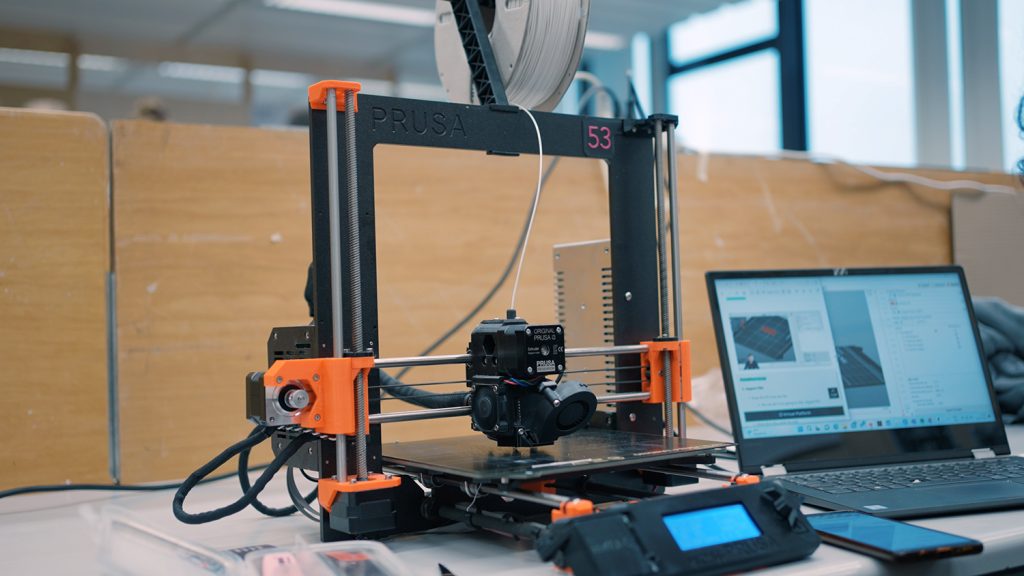

Our 3D printers are in regular use at the Department of Architecture here at ETH. Jonathan Benhamu, the founder of HYTAC (Hybrid Techniques for Architecture Design) and a lecturer at the Chair of Professor Andrea Deplazes, teaches his students about the capabilities of modern hybrid modelmaking technologies and how to leverage them best in an architectural design workflow. Each and every architecture student at ETH gets the opportunity to participate in the HYTAC Basics program, which goes hand in hand with the design studio lectures by Professor Andrea Deplazes. The HYTAC Basics course takes place in the first year of the architecture bachelor program. Students wishing to further pursue their interest in the hybrid model-making will find the perfect opportunity in HYTAC’s elective course: Drone flying, working with photogrammetry data, and point cloud processing are only some of the adventures students can delve into.

“We use 3D printing as a prototyping tool, or as a work-in-progress tool to design buildings in architecture. And we print everything – from whole models to construction details,” says Jonathan, starting off his seminar week just during the time of our visit.

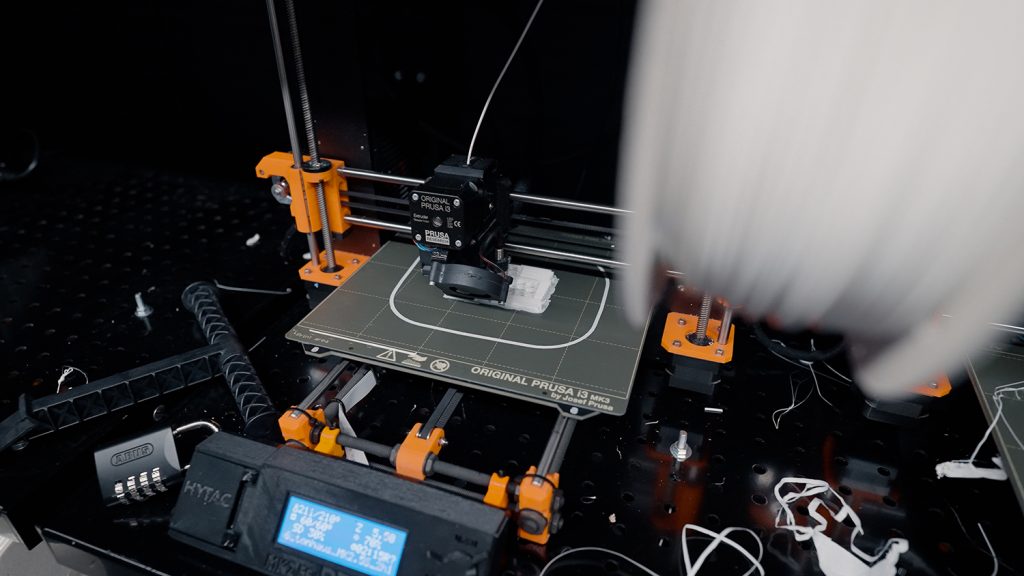

The students have their first encounter with the Original Prusa printers right off the bat. Everything begins with a practical challenge – each student has to assemble their own 3D printer from scratch using the Original Prusa MK3S+ kit.

“Our students build their own 3D printers to better understand what happens mechanically. The better they understand the process, the better they can get the best out of these machines,” explains Jonathan.

At the seminar, there are over 300 students present, divided into groups, each group tasked with a specific exercise. Assembling a 3D printer, preparing a 3D model to print or drawing up a new design in CAD software, there is definitively a new experience for everyone. Everybody is in a good mood and eager to finish the given task, so they can finally start their first 3D print – the atmosphere is great.

“We are very excited to see the 3D printers finally working and to print all the models we have designed. To be able to move them around, look at them from all angles…” says Berith Schumann, one of this year’s newcomers.

For many of the students, this is the first time using or even seeing 3D printing technology. A new kind of technology that definitively sparks a lot of curiosity and a wish to experiment.

„Yes, for the first time.“ admits Berith, adding: „And that is why I wanted to build one myself and see how it works with the X, Y, and Z axes.“

However, the challenge is far from over with the successful assembly. During the rest of the week, the students learn to design, slice, and print 3D models themselves. Step by step, they see their personal designs come to life as real models. And as a grand finale, everything culminates in a large exhibition. After professor Andrea Deplazes opened the exhibition with an inspiring speech, professors, students, and parents alike got the chance to take a look at the impressive results of this week of hard work. The students are proud of what they were able to achieve.

“One of the reasons I started studying architecture here was because I came to last year’s vernissage,” reveals Jonas Jost, a first-year student. “I saw all these models, which I found really interesting, and I wondered how they were made in just one week. And that was thanks to 3D printing.”

“This is the first time I have used a 3D printer,” tells us first-year student Paul Jaeggi. “Thanks to the team of teaching assistants, it’s been very easy to get started. It’s always a different feeling to hold in your hand something you’ve designed yourself. It’s very rewarding.”

Almost 100 Original Prusa 3D printers

The realization of this resource-intensive teaching project was only possible due to the large support the HYTAC received from professor Fabio Gramazio (Chair for architecture and digital fabrication) and professor Andrea Deplazes (chair for architecture and construction). With the backing of these two Chairs, Jonathan launched his teaching activity at ETH Zurich in 2017, which turned out to be a big success.

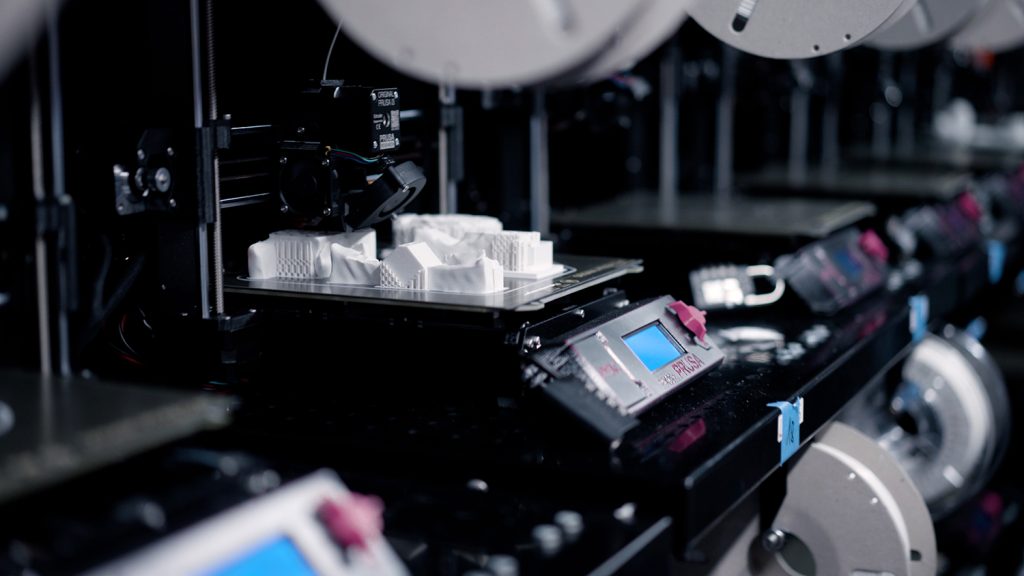

Today HYTAC has almost 100 printers in use – all Original Prusa. The idea to involve students in the assembly and maintenance process was initially born out of necessity:

“We had the means to get enough 3D printers, but we didn’t have the means to pay for the manpower to maintain them. So, we decided to involve our students,” explains Jonathan.

Jonathan adds: “In the end, every 3D printer we have, has been built by our students – so it has the added value of them knowing how it works and being able to fix it themselves.”

Every year, HYTAC sells 20 of its printers to the students at a reduced price and replaces them with 20 brand new ones – this allows it to keep the 3D printing lab up to date at all times.

The 3D lab is located on the roof of the building, which houses the architecture department. It was set up in collaboration with the chair of Professor Andrea Deplazes inside a specially developed high-tech container. And it is just mesmerizing to just stand in the middle of the lab and look at all the printers doing their job. But the best part is definitively when the students come to retrieve their creations from the printing bed: They’re proof that there’s nothing better than seeing your own creation after a successful print. 🙂

“The first 3D printing lab was just a shipping container where we had problems with overheating, and the air quality was not optimal. The new one is so much better,” informs William Schaeppi, a teaching assistant in charge of the 3D printers, before he starts a tour, showing us around the lab.

All 3D printers are housed in a temperature-controlled and well-ventilated room, safely stored behind glass doors. Providing measures for fire safety, ventilation, and air filtration is key to operating such a large number of printers. Soon, the 3D lab will transform again: An update to a new rack shelf system is awaiting, facilitating access to the printers in day-to-day operation as well as for repair. What a lab!

William himself is a big advocate of 3D printing and uses it often for his own architectural projects:

“It’s an amazing way to express yourself. So different from a cardboard model. With a 3D printer, you let the machine do the work, and you can focus on the concept. I couldn’t imagine my life without 3D printing,” says William Schaeppi.

Five years of experience

Jonathan Benhamu has been researching the integration of 3D printing technologies into architectural design for over five years. The idea of using a 3D printer for his own architectural practice came from his wife:

“I had little money and a lot to do. And a 3D printer just works and doesn’t ask for coffee!” smiles Jonathan. And adds: “With a 3D printer, I quickly saw the potential of this technology and I can see it being used in every aspect of architecture.”

Thanks to the support of Fabio Gramazio (professor of architecture and digital fabrication) and Andrea Deplazes (professor of architecture and construction), Jonathan was able to start his teaching activity at ETH Zurich. Therefore, he has created his online learning platform for architects, “3D Jony”, which shows how easy it is to get started with 3D printing and how architects can benefit from it in their daily workflow.

Why Original Prusa printers

“We chose Original Prusa 3D printers because they are the easiest to maintain,” says William Schaeppi. “You can reprint a part, take the printer apart, and put it back together very quickly. And there’s also very good documentation online.”

“What I like most about Original Prusa 3D Printers is the community. The spirit is absolutely fantastic. I encourage my students that, if they have a problem, they can just type it into Google and add the word ‘Prusa’ at the end. And they’ll probably get an excellent answer from someone anywhere in the world,” tells Jonathan Benhamu and smiles.

His students agree with him.

“Original Prusa 3D printers are really easy to use, and thanks to the courses, the community and the PrusaSlicer, it’s really easy to get started with 3D printing,” says Jonas Jost.

“We’ve had minimal training, but with just a few tutorials, it’s really easy to understand 3D printing and get up and running quickly. It’s nice to have such a simple and easy-to-use solution,” says Paul Jaeggi.

3D printing is essential

“The students love it,” says Jonathan Benhamu. “I can’t imagine a world without 3D printing. It just wouldn’t work! We are constantly increasing the value of the man-hour, and anything that can reduce or remove tasks and give them to a machine is going to be essential in the future,” says Jonathan, leaving us with a plea for the use of 3D printing in architectural design.

“It’s up to every professional to find a way to implement this as such and promote the value of human intelligence!”

Thanks

Thanks for great sharing here.

dino game!