We launched Prusament PLA Recycled last December and it became an instant hit, so it only made sense for us to continue our work so we can bring you PETG Recycled! We’re launching it today and we’d like to share some details not only about the material but also about our production process, sustainability and environmental impact.

The universal can press from the picture can be downloaded here.

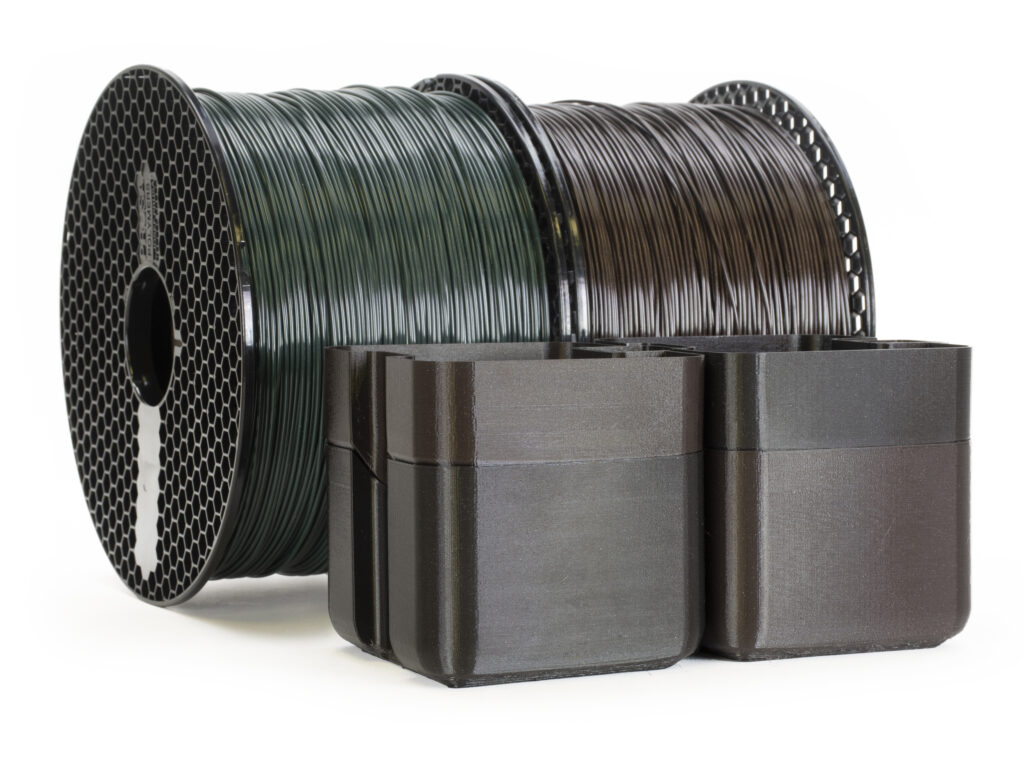

Prusament PETG Recycled is sold on 2 kg (4,4 lbs) spools with the same price as Prusament PLA Recycled – 54.44 USD / 46.99 EUR (incl. VAT) per spool. The filament is made only from waste generated during manufacturing of Prusament PETG, and not from, e.g., failed prints. Therefore, you’ll get a 100% pure Prusament. The color of Prusament PETG Recycled varies between batches because it depends on the color of the waste it is made from. This way you’ll get a different, unique color every time you get a spool of recycled Prusament.

There’s one more thing worth mentioning: we launched Prusament PETG Recycled once we’ve received results on Life Cycle Assessment (LCA). This has been calculated for our PLA and PETG Prusaments (and their recycled siblings) and the plan is to get results for more of our products.

What is LCA?

The LCA (Life Cycle Assessment) is the only complex tool that evaluates the environmental impact of the product’s whole life cycle. It is the only tool respected all around the world. The LCA method counts with a man-made ecological footprint from mining (farming) resources, through transportation, to packing the filament into the box (our case). The outcome of this method is not only one number but a complex package of effects on various parts of the environment.

Among observed parameters are, for example, acidification (SO2 eq), eutrophication (PO43- eq), greenhouse gases (for example CO2, methane, N2O), etc. For those really interested in this matter, there’s an extensive article about various LCA categories, however, for everyone else, we have a bit more streamlined example: our filaments and the amount of CO2 produced during their manufacturing. The result for the selected product is the sum of CO2 kilograms equivalently released in all stages of the product’s life cycle. This is often described as the product’s carbon footprint.

Carbon footprint of our filaments

We had the LCA calculated for Prusament PLA, PETG, and their recycled variants. We tried to be as precise and thorough as possible, that’s why we got the calculations for all LCA categories. The results consist not only of the manufacturing process itself, but also include everything related to transportation, water used during manufacturing, power consumption in the production of molded parts, and grinding the Prusament (for recycled versions).

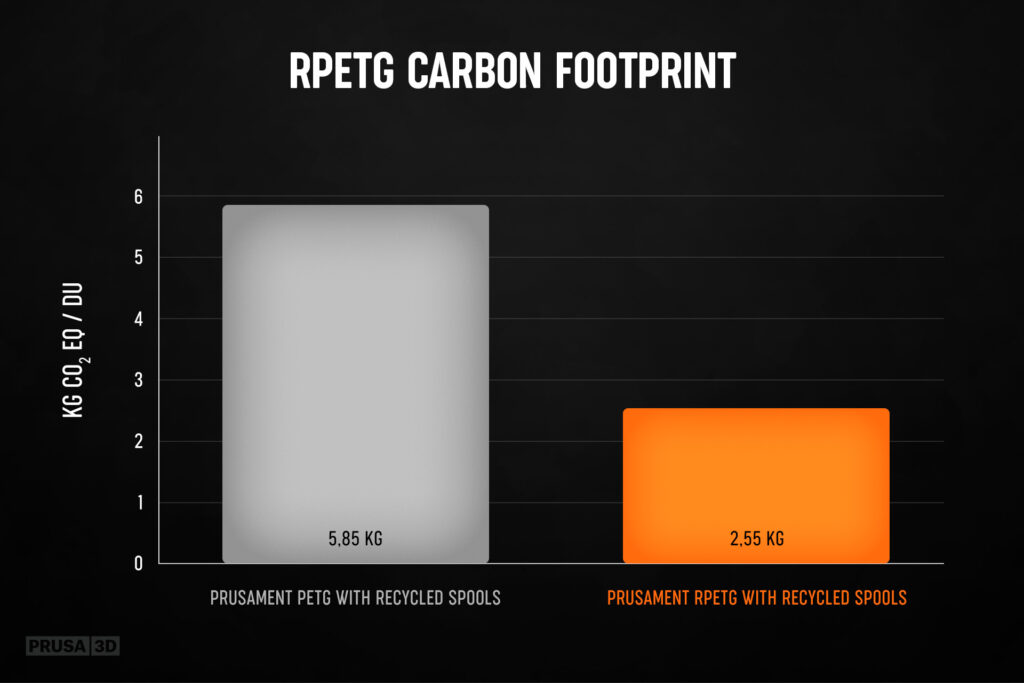

And how did it turn out? Let’s compare CO2 emissions between our new Prusament PETG Recycled and pure Prusament PETG, for example. The results show 5.85 kg of CO2 with 1kg of pure Prusament PETG, whereas 1 kg of Prusament PETG Recycled comes with only 2.55 kg CO2 emissions thanks to leaving out the transportation and production of new granulate. Therefore, the production of one spool of Prusament PETG Recycled releases 3.3 kg (56 %) less CO2 amounts compared to the pure Prusament PETG.

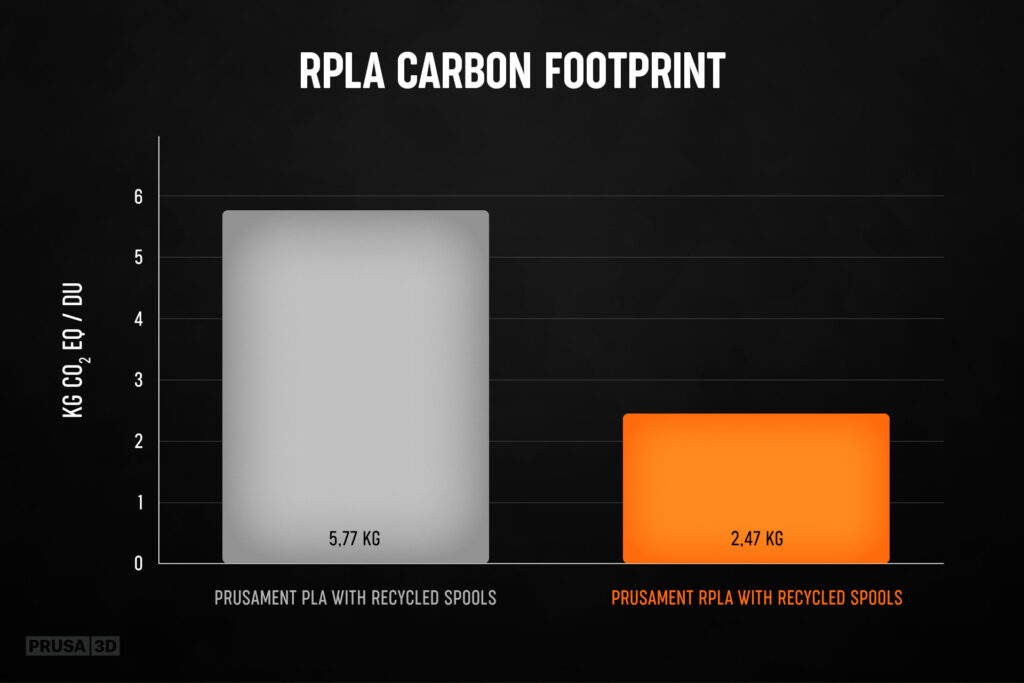

And with the Prusament PLA Recycled, we managed to lower the CO2 emissions by 57 %, from 5.76 kg to 2.47 kg.

The LCA study was made by Ing. Marie Tichá, a highly regarded specialist in this field. She has dealt with LCA since 1993, she is a member of TNK 106 by UNMZ and represented the Czech Republic at international conferences ISO/TC 207/SC 5, where she participated in making ISO 14040 and 14044 (LCA) norms.

Why is LCA so important for us?

Thanks to the LCA we know how much energy and emissions get released into the environment with every single piece of the life cycle chain. This way we can focus on specific parts of this chain (production of pure granulate, packing, transportation, etc.) and work on improvements. The effect is clearly visible with recycled Prusaments where we skip the production of a primary resource (oil extraction, corn farming), granulate production, and transportation from supplier to our company.

What’s next?

In the following weeks, we’ll prepare a detailed LCA overview for tested products, which will be free to download on our e-shop. We see the LCA as a powerful tool for making the right steps in the manufacturing process of our products. It should be in the common interest to minimize ecological footprints. Nowadays, the LCA and sustainability are generally considered important and we want to set an example. We’re already working on LCA calculations for our 3D printers and plan multiple steps that will lead to a more ecological form of our production. However, it’s not only on us – anyone can join the effort. If you have any ideas and suggestions, don’t hesitate to share them with us.

Happy printing!

SimaPro 9.3.0.2. computer model was chosen for this study. This is an LCA software used for calculating inventory analysis (LCI) and results of indicators of impact categories (LCIA). The software was developed by PRé Sustainability, which is a trademark of © PRé Consultants B.V., Amersfoort, The Netherlands. For more information visit www.simapro.com

I hope this product works out better than your PC Blend Carbon Fiber. Due to the nature of the carbon fiber, “Carbon fibers inside the filament are made by recycling waste from the manufacturing process or from carbon composites after the end of their lifespan,” the product results in very expensive garbage. I keep it around in case I need to print something that is long, thin and tall because it warps very little, if any at all. As far as strength goes…. “it’s disappointing” is an overstatement.

Hello

Is it possible to receive the Material table as one page not 3-4 pages? I want to print it as poster !

pls. advise [email protected]

Great idea and great product.

For the future:

2kg Standard PETG-spools would be nice. Or even bigger spools.

Great! I think it’s really nice that you put genuine effort in reducing the carbon footprint. It’s a lot of work (I know from school) and it doesn’t help you make a lot more money. So to me if a company does these things, it is because they want to make the world a better place. Great job and keep up the good work! I’m looking forward to what you guys are going to do next!

Cool, I think it would be cool if we could buy this with prusameters.

I again would like to suggest refill spools for master spool standard.

That could reduce your footprint without any extra cost 🙂

I’m not sure there is a master spool standard for 2 kg rolls yet 🙂

However, your comment is spot on, and I’d love to be able to order spool-less filament, not only to reduce the carbon footprint but also to avoid plastic waste!

Thank you very much for your efforts! I find this very important and interesting.

I hope that these recycled Filament roles get sold in Canada. It is of no advantage to pay shipping,handles and processing fees. As well to reduce the Carbon footprint if bulk rolls were shipped in quantity to dealers in Canada (or US) that would reduce the carbon emission. Not only on the bulk shipping but remove the individual shipping from the final over seas shipping destination to the purchasers home (separate delivery).

I beleive that the labels on the graphs are incorrect. Both descriptions say “with recycled spools”. I beleive that the left hand column should be lableled “without recycled spools”.

Anyone knows what the width of the spool is?

I wonder if this spool would fit on my spool holder.