Today, we’re celebrating an anniversary – it has been exactly one year since we released our first SLA resin! So far, we have launched Prusament Resin Tough, a material perfectly suitable for extremely fast, detailed and reliable 3D printing of visual models such as action figures, busts, prototypes, casting molds, etc. With the launch of our first resin, safety was the highest priority along with extremely high reactivity and resolution. However, we feel that resin safety issues are not stressed enough among the users and we would like to address the issues such as: What are stereolithographic resins, what are their health hazards and what can be done to increase safety?

With this article, we take our chance to enlighten you on some critically important aspects. Also, you can check out the advantages of using our resins over the competition’s.

A little bit of chemistry at the beginning

First, we need to clarify some basic chemical concepts of how stereolithography resins actually work and what their composition is. This brief lecture is necessary to fully understand the issues we are addressing not only in this article but also during your work with the resin. Buckle up, here comes the chemistry.

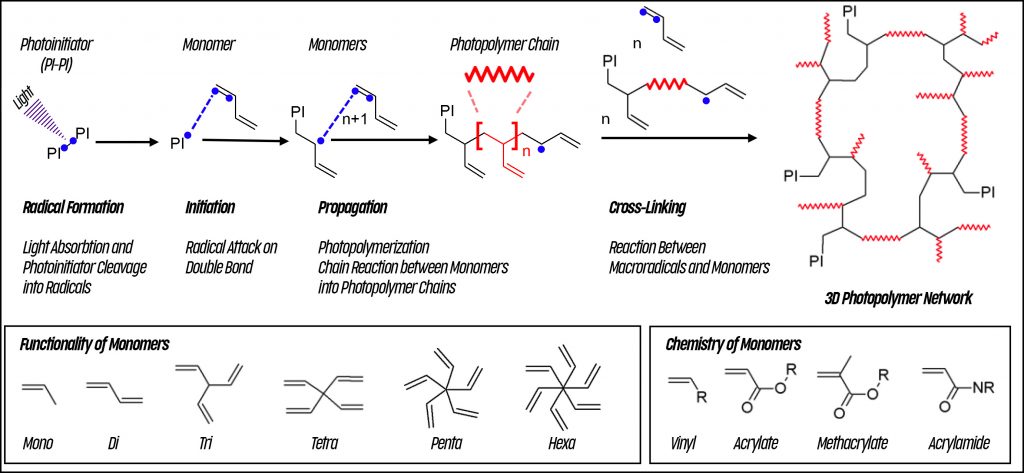

The most common chemical mechanism for the solidification of liquid stereolithography resin into solid objects is a process called radical photopolymerization which is triggered by light of a certain wavelength penetrating into the resin through the LCD. After the light absorption by photoinitiator molecules, initiating species are formed. These species are called radicals and initiate chain growth polymerization via attacking the double bonds in monomer molecules. In consequent reactions, monomers are linked together through the double bonds forming the polymer network and solid objects (schematically depicted in Fig. 1). This process is repeated layer by layer during 3D printing. The most common and the most reactive monomers might be found among the acrylates, methacrylates, or acrylamides. Various photopolymer structures are formed based on the number of reactive groups per monomer molecule, from linear photopolymer chains to densely cross-linked photopolymer networks. The group of possibly used photoinitiators is equally extensive and their description is beyond the purpose of this article.

Fig. 1: Schematic depiction of chain growth photopolymerization

While monomers and photoinitiators contribute mainly to reactivity, mechanical properties and toxicology, resins also contain other important chemical components such as pigments or dyes, fillers, stabilizers and additives required for overall performance. These components need to be perfectly balanced. In our raw materials choosing process, three main criteria need to be met in order to introduce a quality product: extremely high reactivity of the resin, suitable mechanical properties which you are looking for, and lowest possible toxicity.

Health hazards of the stereolithography resins

To obtain a little perception about resin toxicity, we introduce you to a system called Globally Harmonized System of Classification and Labelling of Chemicals (GHS) which covers the classification of the chemicals substances and mixtures, universal warning pictograms, and harmonized safety data sheets. Pictograms below should be the first sign of the resin hazard and visibly labeled on the bottle for your caution. While some of the pictograms might be irrelevant for the stereolithography resins, such as GHS01 or GHS04, the rest might appear on common resins.

GHS01 |

GHS02 |

GHS03 |

GHS04 |

GHS05 |

GHS06 |

GHS07 |

GHS08 |

GHS09 |

It needs to be stressed that resin hazard classification depends on the substances used and their concentrations. And note that the hazard of the liquid resin is usually higher than the hazard of the printed and post-cured resin. A complete list of Hazard (Physical, Health and Environmental) can be found here while Precautionary statements can be found here. Safety data sheets further define a list of hazards and precautions for your resin.

Some of the usual suspects

Stereolithography resin could contain a large number of dangerous chemical substances. For your precaution and warning, we have picked some of the most common chemical substances posing a risk to human health. Note that the following chemicals are being used in tough resins on a regular basis so it might be time to start paying very close attention to safety data sheets and safe resin handling!

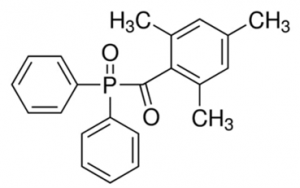

Colorless photoinitiator

Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide or TPO is a commonly used photoinitiator for its unique combination of high reactivity at 405 nm wavelengths and its ability to create colorless to off-white formulations. While other photoinitiators at 405 nm cause significant yellow color or suffer from low reactivity, this substance is abundantly used in transparent, white, blue, gray, beige, or pink-colored resins (light and cold shades). Despite the benefits, the substance is suspected of damaging fertility, it may damage fertility or affect unborn children (ECHA) and its presence should be stated in the SDS. Analysis of various commercially available resins (mainly from China) via UV/VIS absorption indicates the presence of the substance in the resin while SDS did not state the substance. We are working on intensive research to replace this substance while getting similar or even better properties.

Diphenyl(2,4,6-trimethylbenzoyl)-phosphine oxide |

H317 – May cause an allergic skin reaction. H361f – Suspected of damaging fertility. H411 – Toxic to aquatic life with long-lasting effects. |

|

|

Ultrastrong and ultrafast monomer

4-Acryloylmorpholine is used due to its excellent mechanical robustness and extremely high reactivity. The substance’s drawbacks might be worse toxicology and characteristic and unpleasant odor. For us, these aspects determine the usage of this substance only in special, high-performance resins, mainly for engineering applications.

Tough and fast monomers with some issues

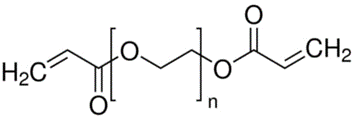

Poly(ethylene glycol) diacrylates are excellent monomers for their flexibility, toughness, low viscosity and high reactivity. The properties can be tuned by the length of the polyethylene glycol unit. Unfortunately, the group of these chemicals causes serious eye damage when exposed to the substance. This results in the classification of the substance as H318 (Serious eye damage – Category 1), which also means that the substance and consequently the resin gets a label GHS05 – Corrosive. And we do not like that.

Poly(ethylene glycol) diacrylate |

H315 – Causes skin irritation. H317 – May cause an allergic skin reaction. H318 – Causes serious eye damage. |

|

|

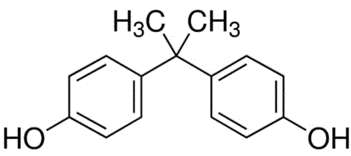

An industrial standard with a controversial structure

There are various chemical structures of bisphenols but the most common is Bisphenol A. Generally, there are many types of Bisphenols and these may damage fertility, disrupt human and animal hormonal systems or cause skin allergies if they‘re in molecular form. In turn, the European Union included Bisphenol A among substances of very high concern.

The situation for Bisphenol A monomers with double bonds such as acrylate or methacrylates bound to it might be a little different when compared to single molecular Bisphenols. These monomers usually do not pose health risks according to their Safety Data Sheets. In fact, these monomers are industrial standards or workhorses used in multi-purpose resin such as dental filling or stereolithography applications due to their high reactivity and mechanical robustness and their toxicology hazard might be questionable. For example, Bisphenol A can be found also in thermoplastics such as PC (Polycarbonate).

The general trend is to avoid such substances to decrease any possible health risk – so that’s what we do. Maybe you have noticed products of daily use with a labeling Bisphenol A Free (BPA Free) and it’s something we can put our resins, too. You can read this ECHA article for more info about Bisphenol concerns.

Our approach

General strategy of our Pruscientists is to avoid dangerous substances, reduce the hazards and develop resins with low toxicological hazards without sacrificing printing quality and reliability. We think that this is an especially important rule for formulations of the resins for hobby, sculpting, fast and reliable prototyping usages, such as our Prusament Resin Tough series. In other words, resins with high exposure of customers to liquid or cured form and for applications that do not require ultra-high mechanical performance should be made as safe as possible. In this case, the worst accepted classification for our Prusament Resin Tough is GHS07 or GHS09 which are almost impossible to be avoided for the final resin formulation.

The usage of more dangerous substances might be reasoned only when there is no other chemical counterpart and there is simply no way around mainly with regard to properties, for example for high-performance resins.

Now, the question is are there any benefits and do we have any results that support our decision? Or is it just us being too scared of a little bit of chemistry? The short answer is: yes, we have done some tests and it certainly makes sense to be cautious. Let’s have a look at our data.

Experimental part

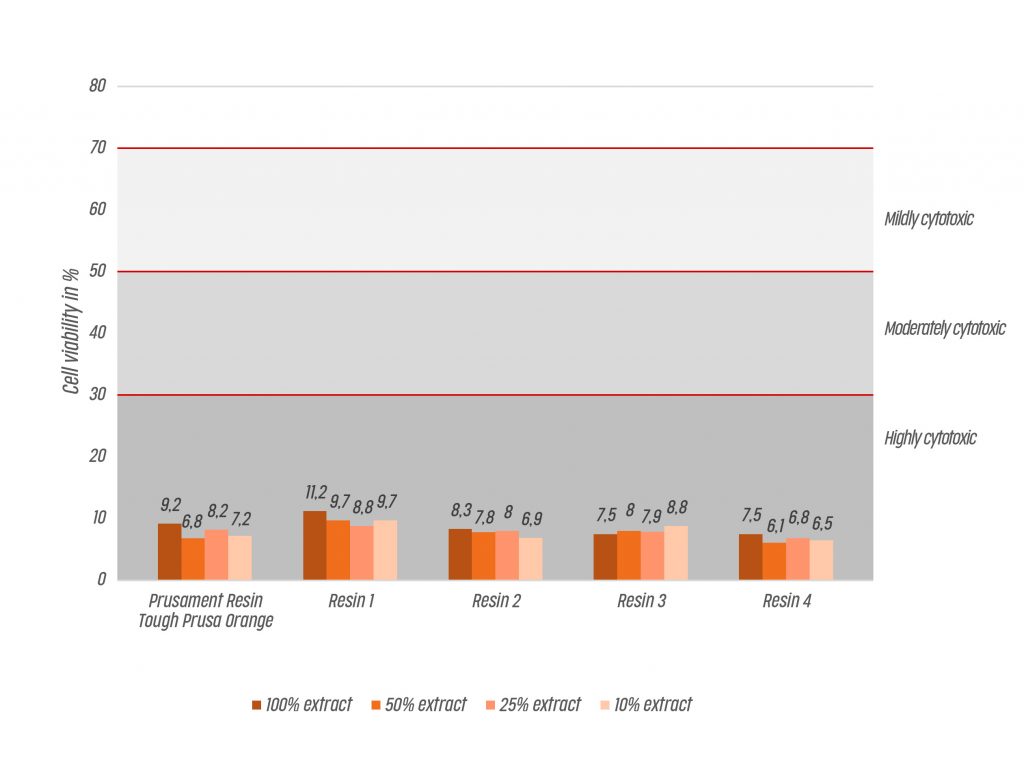

Cytotoxicity

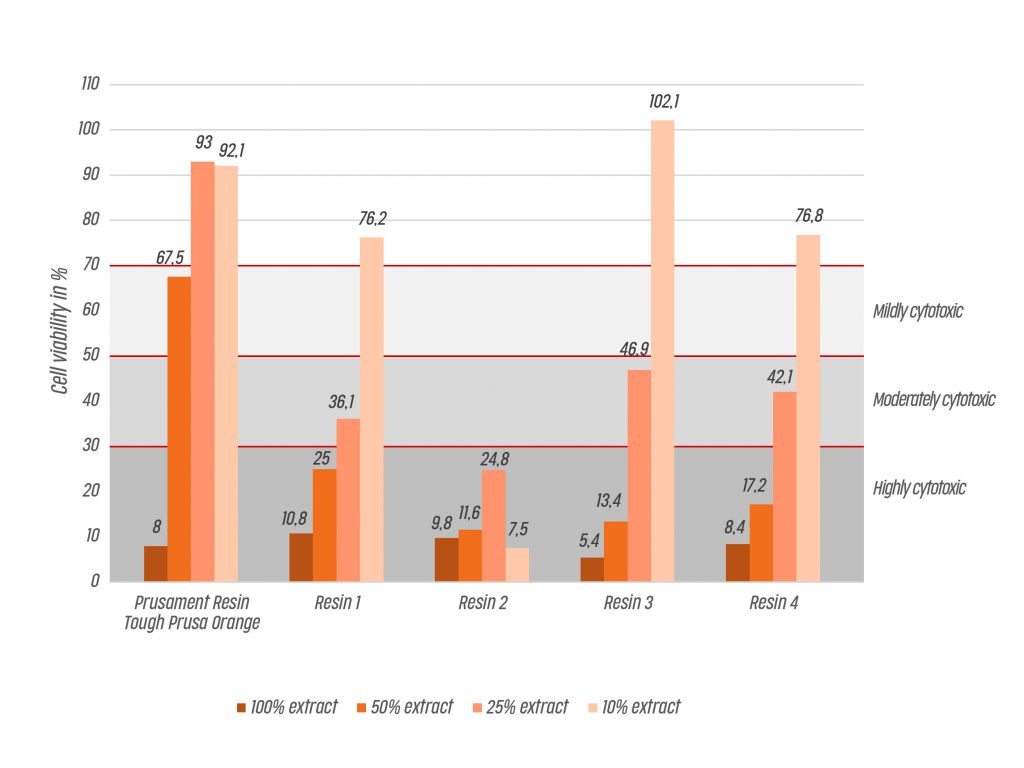

We have conducted cytotoxicity tests for Prusament Resin Tough (Prusa Orange) and four other common competition resins. The samples were tested in a certified testing laboratory, where the effect of the resin and 3D printed objects on cell viability was measured.

Mice skin fibroblasts were used as testing cell culture. Fluorescent dye is used for further analysis of the relative fluorescence intensity as an indication of how many cells survived or died compared to unexposed living cells. The liquid resin or 3D printed objects were immersed into the physiological solution* supporting living cells for 24 hours. After that period of time, extract with various concentrations (100, 50, 25, 10 %) was put in contact with the cells for 24 hours. After that period of time, the relative number of living cells was measured.

*DMEM medium containing antibiotics with 10% inactivated veal serum

The specimens were marked as highly cytotoxic, moderately cytotoxic, mildly cytotoxic and non-cytotoxic with the following percentage of living cells:

- Highly cytotoxic: 0 % – 30 %

- Moderately cytotoxic: 30 % – 50 %

- Mildly cytotoxic: 50 % – 70 %

- Non-cytotoxic: 70 % and more

These tests follow the standard testing procedure ISO 10993-5:2010.

Liquid resin comparison

To see what the resin does with living cells, we prepared samples of liquid, uncured and cured common tough resins available on the market. If you have a look at the results below, you’ll see that all liquid resins are highly cytotoxic. This underscores the necessity to handle the resin with caution and as described in the safety data sheet. And to limit the exposure to liquid resin and its residues on the 3D printed models or in the washing solution, while using proper protective equipment, such as gloves, goggles, etc (as described in Safety Data sheets). Basically, any kind of additional safety protection measures such as increased ventilation or a fume box is only a plus.

Fig. 2: The effect of extracts of various concentrations from 3D printing resins in liquid form on the cell viability of the mice fibroblasts (cytotoxicity). A decreasing number of living cultivated mouse skin cells were observed during a 24-hour period at 37 °C in this test. Mild, moderate and high cytotoxicity levels are represented by shades of grey.

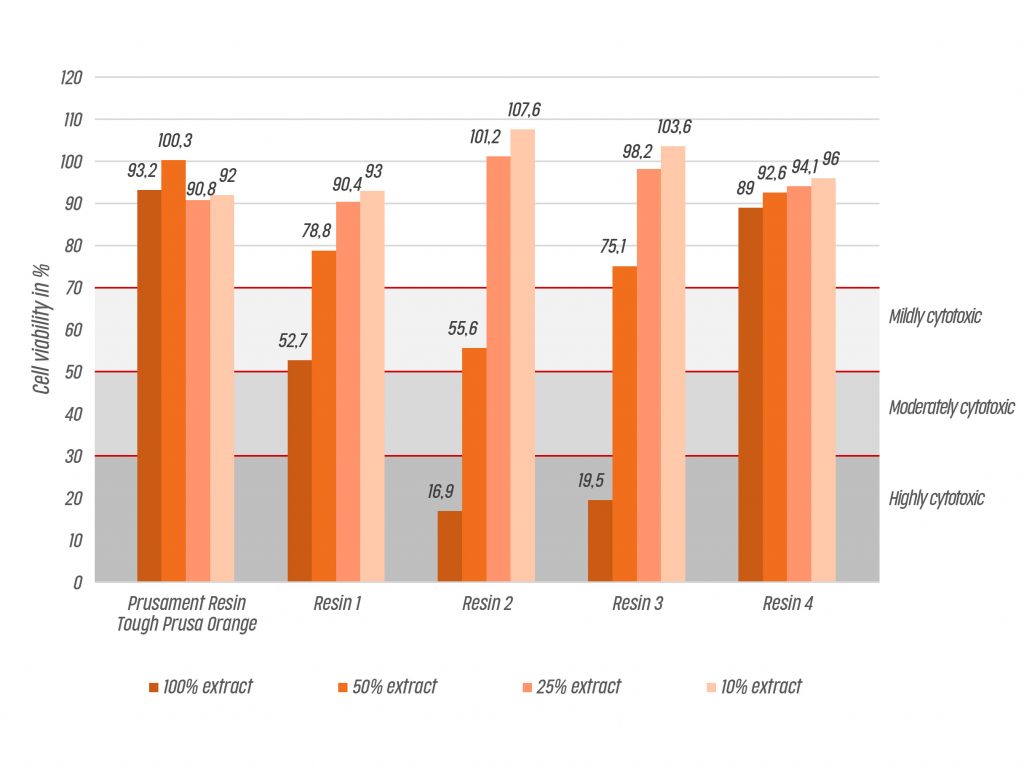

Uncured and cured resin comparison

The results for the liquid resins are quite straightforward but things get more positive after the curing procedure. The cytotoxicity of the 3D printed and cured specimens is significantly decreased when compared to liquid resins. But most importantly, we can observe more significant differences between the tested brands. For this test, we used two sets of specimens: the first was washed in pure isopropanol (IPA) while no heating and curing step was applied (samples are marked as uncured), the second set was washed and then dried at 45 °C and cured in CW1S for 3 minutes (samples are marked as cured). Therefore, this test characterizes the cytotoxicity of 3D-printed parts directly after the 3D printing process and parts after the post-curing procedure.

The results show that it is rather unwise to touch models with bare hands after printing, we suggest doing so only after additional curing when it is safe. To get the lowest possible cytotoxicity, it is necessary to follow the manufacturer’s instructions for curing (curing temperature and time, curing machine usage, etc.). Our Prusament Resin Tough exhibits low and constant values for cytotoxicity even after one minute of curing!

Fig. 3: The effect of extracts of various concentrations from 3D printed and washed (further uncured) parts on the cell viability of the mice fibroblasts (cytotoxicity). A decreasing number of living cultivated mouse skin cells were observed during a 24-hour period at 37 °C in this test. Mild, moderate and high cytotoxicity levels are represented by shades of grey.

Fig. 4: The effect of extracts of various concentrations from 3D printed, washed, dried and further cured parts at 45°C for 3 minutes on the cell viability of the mice fibroblasts (cytotoxicity). A decreasing number of living cultivated mouse skin cells were observed during a 24-hour period at 37 °C in this test. Mild, moderate and high cytotoxicity levels are represented by shades of grey.

We find it quite interesting (and alarming) that some of the cured tough resins show strong toxicity (for 100 % extract). Concerning our standards, the Prusament resin tough and specimen 4 are well within the limits.

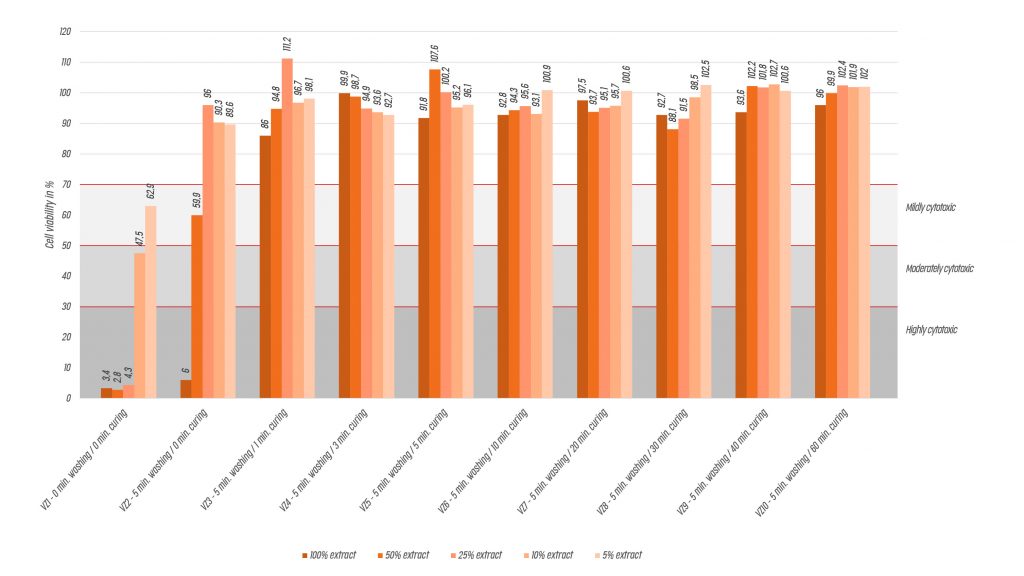

Fig. 5: The effect of extracts of various concentrations from 3D printed parts with various post-processing protocols and post-curing time on the cell viability of the mice fibroblasts (cytotoxicity). A decreasing number of living cultivated mouse skin cells were observed during a 24-hour period at 37 °C in this test. Mild, moderate and high cytotoxicity levels are represented by shades of grey.

Another set of tests for the skin irritation effect showed that short exposition to a well-washed 3D print is well within the limits. However, we suggest curing models for at least 3 minutes to get the best results, concerning cytotoxicity.

Note that these tests do not completely reflect long exposition in small doses. Even though some resins may come with good cytotoxicity, they may still cause health issues after repeated exposure. Again, this is why we do not use highly toxic chemicals as stated above.

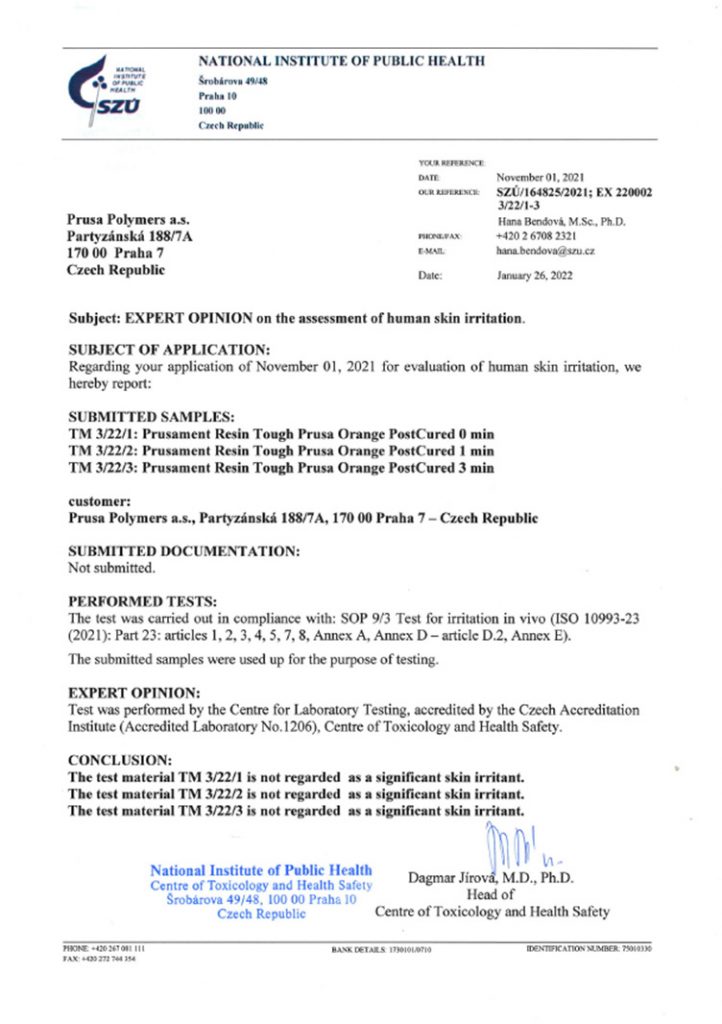

Skin Irritation

Plates with dimensions 2.5×2.5 mm and thickness of 1.0 mm were printed using Original Prusa SL1S SPEED. The exposure time was 2 seconds per 50 um layer and 25 seconds for first layers while plates were standing on the supports – thus investigated specimens were fully printed with 2 seconds per layer. Further samples were washed in clean isopropanol for 3 minutes and post-cured for 0, 1, or 3 minutes. Prepared samples were applied directly on the skin of 30 volunteers for the period of time 24±2, 48±2 and 72±2 hours. Sodium dodecyl sulfate was used as a positive skin reaction reference (0,4 ml of 20% aqueous solution was directly applied to the skin of volunteers). After this period of time, skin reaction was evaluated with grating as follows:

0 – No Reaction;

1 – Weakly positive reaction (usually characterized by mild erythema and/or dryness across most of the treatment site);

2 – Moderately positive reaction (usually distinct erythema or dryness, possibly spreading beyond of the treatment site);

3 – Strongly positive reaction (strong and often spreading erythema with edema and/or eschar formation).

The procedure of the tests follows the standard testing procedure: Tests for irritation in vivo (ISO 10993-23: 2021 Biological evaluation of medical devices).

While sodium dodecyl sulfate evoked a positive skin reaction within 1-3 grating scale among 30 volunteers (with no 0 result), analyzed samples 3D printed from Prusament Resin Tough Prusa Orange exhibited no skin reaction with a sharp 0 grating result among all 30 volunteers regardless of post-curing or application time. The certificate of the analysis from the certified laboratory can be viewed below.

Keep it clean

Speaking about long and short exposures leads us to a proper workplace layout and precautions limiting exposure to dangerous substances. If you want to keep everything clean and safe, you should follow these rules and recommendations:

- Work in a well-ventilated room. In general, keeping your printer and working with resins under a fume hood might be the best but for the common resins, open windows or well-ventilated rooms should be enough.

- Have your workplace set on an easy-cleanable surface. A clean table might work the best but you can also use disposable paper tablecloths that may be changed when polluted. Also, their sorption ability helps to prevent spilled resin from further polluting.

- Place the printer in a disposable tray. If the resin leaks from the vat, it won’t get far.

- Always have paper towels within reach and every time you spill anything, wipe it instantly.

- Always use disposable gloves and protective eyewear. Some resins may trigger an allergic reaction, especially if you suffer from eczema or your skin is sensitive. And you don’t want to deal with resin in your eyes…

Note that some gloves may be partially dissolved by isopropanol or some chemicals used in SLA resins. With long and repeated exposure, some gloves may eventually crack. We suggest disposing of the gloves after every use or using thick gloves for repeated use. - Get a lab coat or any other working coat that protects you from exposure to chemicals. Imagine a situation where you shake a bottle of resin and quickly find out that the bottle is punctured or not properly closed.

Fig. 6: A good example of SLA workplace setup

Technical datasheets

Finally, don’t forget to read the technical data sheet thoroughly for the resin you buy. Except for mechanical properties, there should also be important information that is closely related to health safety and information from the safety data sheet. There should be recommended printing times, information about washing, drying and post-curing procedures. We found out that for some resins, this information is often available online on shared google sheets, sometimes it is in a safety data sheet and sometimes it’s incomplete or not available at all. We believe that this should be clearly arranged and stated in the technical datasheet.

Basic usage of SLA 3D printing may not be rocket science but there are obviously some rules worth following to keep it as safe as possible. It all comes down to reading datasheets thoroughly to find whether it’s safe or not and using the right protection. We hope this will help you to be as safe as possible when printing with SLA.

Happy printing!

As a chemical engineer I do appreciate this post a lot. But please check your disposable cloves material (latex, nitril, tpe, vinyl, …) and check if they withstand your cleaning agent. (isopropanol, acetone, … ) If they are not resistant against it, but do solve the resin, they will transport the resin directly onto or even worse into your skin. So please be careful!

Great write up, I recently looked into resin printing and this is the exact kind of detailed information I need and expect from Prusa! Thank you.