Hi everyone, I know you’ve been waiting for news about the XL for quite some time and we’re sorry we’re overdue! We have made substantial progress on the XL in the past few months and now we’re wrapping up the hardware development of the XL and focusing on finishing the firmware.

The ongoing issues with sourcing key components

Unfortunately, both the testing and upcoming production are heavily affected by the current state of the market. Sourcing parts right now is incredibly difficult. We are struggling to find parts for our testing units, let alone suppliers we can rely on when we ramp up into full production. We tried to be one step ahead and even secured our own SMT manufacturing line so we wouldn’t be so dependent on external suppliers, but the availability of electronic components still limits us. We went as far as redesigning the entire electronics of the XL because some components (which used to be very common) were suddenly no longer available – this was described already in the previous dev diary.

Now, for obvious reasons, I can’t list all specific part numbers we’re having trouble with, but I don’t want to be too vague either. The XL uses plenty of Hall sensors, 1-wire serial EEPROM chips, and STM32 chips just to name a few we’re having trouble with. Traditional suppliers are dry and when you go to AliExpress or similar websites you will probably find out that there are sellers that have literally hundreds of thousands of these components – so where’s the problem? Once you contact the supplier, you’ll probably hear something like “Sorry, we just checked and the number on the website is not correct, we have only a few thousand units.” and the lead time will be somewhere between 1-2 years. Some suppliers will attempt to send you low-quality knock-offs which is a huge issue. For us, it means we have to check everything thoroughly, Xray the components or decap (disassemble) the chips to see whether we’re getting genuine parts. I think it goes without saying that we don’t want to use any clones either (GD32 vs STM32) because while they may look good on paper, the reality is often vastly different. These clones may be fine in a cheap DIY controller for an LED strip, but definitely not in a machine like this.

We’re using multiple sourcing agents to get the required parts. The situation is so dire and there are so few batches that it actually happened more than once that they kept bidding on the same batch of parts and kept outbidding each other.

So in all seriousness, if you have some magical sourcing powers, do let us know!

Long story short: we are facing major manufacturing setbacks due to the unavailability of key components. We’re constantly looking for new options and new suppliers, but the truth is that we need to postpone the start of production. Just a few months ago everything looked like the production could start by the end of September. With the current delivery dates for required components, we’re looking at the beginning of December. If we’ll get everything in time, we can send the first batch (a couple of hundred units) at the turn of the year.

Due to the unavailability of major components, it may take us up to 6 months to fulfill day-1 preorders. I understand that this is going to be a letdown for many of you. We will publish more regular updates to keep you on track with our progress.

Hardware upgrades

How about some good news, though? Since the last published dev diary, the team made significant progress on the hardware and there are some new things we haven’t shown anywhere yet. There were some necessary changes to the XL to increase the printing quality and overall reliability. Even with the toolchanger, advanced electronics, new sensors, and reworked extruder, the XL will still be a fairly straightforward machine that will be easy to maintain. Everything will be nicely accessible and ready for your mods and DIY hacks.

Plus, we’re using the extra time to fine-tune the firmware – the electronic boards in the XL are full of various sensors which allow us to monitor the machine in ways that weren’t possible before. Let me give you a little sneak peek at the new changes.

Introducing the Next-Nextruder

When we announced the XL, it featured a cycloid gearbox which provided great results. Eventually, producing it in large quantities with the required level of quality proved to be too difficult as there would be a massive amount of scrap. However, we ran the development of another solution in parallel – a planetary gearbox. It has very similar characteristics but the production is much less demanding and the printing quality has actually improved (more consistent extrusion).

The new planetary gearbox has a 1:10 gear ratio and while there’s a negligible backlash present, it doesn’t affect the quality of the print because it is consistent and we can compensate for it in the firmware easily. Each print head now features an accelerometer so we can see perfectly how it moves and vibrates (great for tuning the speeds) and we have recently replaced the previously shown X/Y axis motors with stronger and faster models. We are still adjusting the parameters to find the perfect balance between speed and quality.

As I wrote previously, we’re not looking to set any crazy records – but I’m not saying that “speed does not matter” either! The point is that the mechanical properties of these super-fast prints are very poor and they are usually nothing more than showcase prints because at ultra-high speeds, the layers adhere very poorly. So, speed does matter (especially with huge prints) and the XL will be significantly faster than our current line-up, but not at the expense of quality and mechanical properties/functionality.

The switch to the planetary gearbox is a rather recent change, so once we fine-tune it to perfection, we’ll be ready to share some numbers and show the printing speed on video.

One of the key components that will greatly affect the speed is also a high-flow nozzle, which will be available at release (we’ll share more details later).

Hardware Updates

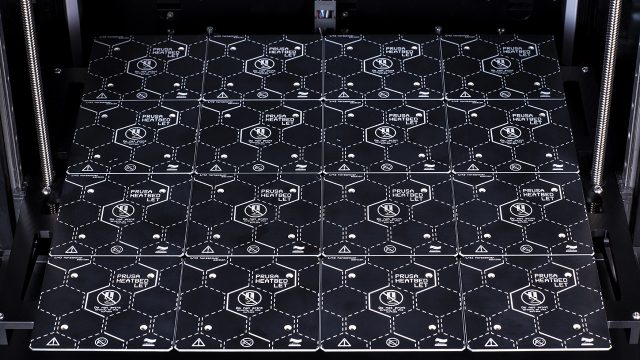

The new segmented heatbed was extensively described in the original announcement text, so I won’t go into too much detail here. Basically, what we have is a set of special heatbed tiles with gaps between them, this is to prevent warping and also to make the heat-up process (and temperature control) more efficient.

The XL uses a matrix of 4×4 tiles, each individually controlled by a special heatbed motherboard. However, with a larger number of individual parts (heatbeds), there’s an increased risk that some produced units won’t meet the required specifications and could end up as scrap. We need all tiles to operate the same way – so they reach the same temperature in a nearly identical time. The printer knows precisely what is the power output of every tile because all of them are checked and measured by the heatbed motherboard. To eliminate potential differences in each of the tiles, we took an extra step and improved their specs. They are now more powerful and they can heat up faster than the heatbed on a MINI or MK3S+. So even if there are some units that are slightly less powerful than the rest, they can still meet the requirements easily.

Even with all the optimizations in place (such as checkerboard-style heating), the XL requires more juice than its smaller siblings. The PSU is one of the last things we need to decide on in the upcoming days and it’s one of the things affected by supply chain issues: we can either use a set of 2 or 3 smaller PSUs with lower wattage or go with a single 1kW power supply. It all depends on the availability.

We’re also working on a full enclosure for the XL. Depending on the situation and measured temperatures, we may consider active temperature controls (with a built-in fan), but nothing is set in stone right now. We also need to consider the space required for the toolheads and PTFE tubes before we release real details. We’ll show more once the design is closer to the final stage.

Firmware Features

The firmware team had to rewrite a major part of the code to make the software compatible with upgraded electronics which cost us some precious time, but we’re back on track.

The segmented heatbed is fully operational and the way it works is incredibly cool. It has its own electronics board and it takes care of managing all the individual tiles. PrusaSlicer now includes the bounding box of the print in the G-code. So the main CPU simply tells the heatbed what it wants to print and it decides on its own which tiles it needs to preheat, saving energy. It can even move the print to an ideal location (e.g. a corner for less warping), unless the user decides to override this behavior. Of course, the Mesh Bed Leveling is performed only in the print area, not across the entire heatbed, significantly shortening the preprint routine for smaller prints.

The XL is very different from the rest of our lineup, but we want to make sure that it’s no more complicated to operate than the MINI or the MK3S+. So even though the printer requires several electronic boards to operate, each with its own firmware, you’ll be able to flash everything at once from the menu.

Right now, the main focus is on perfecting the Mesh Bed Leveling routine and finalizing the code for the updated Nextruder with planetary gearbox. Also, the toolchanger will receive a major speed improvement – we’re currently testing a new update that allows us to push the toolchange time from 10 seconds to around 3-4 seconds. Here’s a little sneak peek, but keep in mind that this is a work-in-progress version, not a production machine. The final speed will be probably different.

More Info Soon

We’ll share more details about the XL soon. I’m fully aware that the last dev diary / update was released several months ago, so I want to make sure the next one comes much faster. We still have a lot of things to show: printing speed, soluble supports, and I want to share more details from the development with you. We’re running late and you absolutely deserve more information about what’s going on. The same goes for pre-orders: we’re aware of the issues with preorder refunds and we have already fixed the issue – we’re sorry for the inconvenience!

Right now, we’re about to start building a batch of nearly one hundred XL 3D printers so the internal beta testing can run at full speed. All the major components for the manufacturing should start arriving in the upcoming weeks and months/years – at this point, we’re basically waiting for our suppliers to fulfill the orders we have placed in previous months. We will also update the shipping table and share it with you.

Thank you for your patience and stay tuned for more updates!

Thanks for the update. I’m sure that most people will understand this. We live in hectic times and we all have to deal with some unexpected situations like delays. Keep up the great work!

It wouldn’t be Prusa when there won’t be a delay in shipping… 🙂

But this shows the amount of work and the time you put into it to ship well working devices.

For me: I can wait, and I have to deal with my own delay in preparing the hobby room 😀

BTW preparing: can you tell us the approximate size of the XL, especially in X and Y? I’d like to mount the spools in a box above the printer, so I am interested in the width/depth of the printer without the spool holders.

Dimensions were shared monts ago…

Q: What are the dimensions of the XL?

A: At this moment (!), the dimensions are as follows:

Excluding spoolholders: 504 mm / 19.8 in. (w) × 535 mm / 21 in. (h) × 660 mm / 26 in. (d)

Including spoolholders: 804 mm / 31.6 in. (w) × 535 mm / 21 in. (h) × 660 mm / 26 in. (d)

However, this is only the machine itself. The printer requires extra room around it for correct operation (e.g., space above the printer for PTFE tubes, space on the sides to place/remove filament spools). This is why you should have a space of at least these dimensions to comfortably run the XL:

1100 mm / 43.3 in. (w) × 910 mm / 35.8 in. (h) × 775 mm / 30.5 in. (d) – this is the absolute minimum of space you need to have on your table or shelf to run the XL without issues.

https://blog.prusa3d.com/wp-content/uploads/2022/04/xl_dimensions.jpg

Concerning space I hope you find a way to reduce the space required around the printer until production starts. Maybe via an option to position the spools above the printer instead to the side of the printer. A surface of 910 x 775 mm is huge for a core xy printer with bed size of 360 x 360 mm. In comparison another core xy printer, the Ender-5 Plus, with slightly smaller build volume (350 x 350 x 400 mm) needs only an area of 650 x 650 mm.

I’d hate to cancel my order in case I find to not have enough space to operate the printer.

How do you avoid oozing from the nozzle when the print heads are not printing, and even just moving from print to park? Even the slightest extra filament would be dire for most prints.

you can see the purge tower on the last GIF with the multi color lama print.

I’m working on projects in the industrial segment with components from Allen-Bradley/Rockwell/Siemens and Cisco.

People who are complaining about 3 month delays have no clue how tough things are right now. I’ve got lead times on normal parts that (in 2019) were 3-6 weeks and are now 9+ months… if someone will even let you order them.

This is life. Keep at it, tell the team to keep up their hard work and stay safe over there!

I know right?! I am a controls engineer in the automation industry and it has been utterly awful. We are still waiting on Siemens and Allen Bradley PLCs and other parts that were ordered last year. There are also issues with ships sitting in the water off the coasts as there is nowhere to unload.

Everyone, there is NOTHING Prusa can do about this unless they are considered an essential customer and are put on a priority list. Such as companies that provide food, necessary goods, or medical. There is just not enough parts to go around and the materials to make these components are also in short supply. Unfortunately, that means extreme delays with no end in sight until the industry stabilizes.

Prusa, kudos to you for going the extra mile to make sure the parts you do get are genuine and not a pile of garbage. I feel your pain and hopefully the industry gets better quick!

I used to purchase automation components for my job and I quit my job because of the delays. Nothing worse than something being 100% out of your control and getting yelled at for it non-stop

Will the 100 testing ones being going to pre-orders after test completion?

“ Right now, we’re about to start building a batch of nearly one hundred XL 3D printers so the internal beta testing can run at full speed.”

Will you please post a list of pre-orders numbers so we know where we stand in the waiting line?

Keep the good progress going, great to be getting closer.

Thanks

Enjoy the day!

Thanks for the update.

It’s good to hear that quality comes first instead of rushing the XL out. The supply chain issues affects nearly all industries, so indeed most of us will understand. In the meantime, it gives us extra time to save money and get our workspaces in order. 😂

no cycloid gearbox is sad… i was really looking forward to this hypnotizeing feature.

i ordered in the first hours… and i did not expect to get it bevore November… (i mean its Prusa… ) but now it sounds like Q2/3 of 2023..

We are exactly where we were when it launched, maybe actually backwards. Some Day One people are ten months from getting theirs- and that is the current estimate, which let’s be honest, is more than likely to slip. When announced, I joked that at least I’d have it for Christmas ‘22. I’d say 50:50 on Christmas ‘23. Heck, by then I might have my MMU2 working consistently…

This is a development project, not a commercial product.

So bottom line for day 1 pre-orders the optimistic timeline is July 2023? Super disappointing, but obviously the chip shortage is what it is. I know you will use the time to make the XL the best it can be so that is exciting. Thanks for the update.

Parece que han cambiado de todo menos el concepto principal de la maquina, la escasez de micro-componentes es una putada. pero cuando salió a la luz parecía estar bastante cerca a un modelo terminado y por lo que parece era todo lo contrario. Por suerte yo no necesito una XL, tengo una mini y una mk3s de las que aun les queda mucho margen de mejora y egoístamente me gustaría que siguieran mejorándolas, la mini tiene muchos defectos aunque es encantadora, se salva por su encanto y la Mk3s necesita una buena actualización, los años ya se notan demasiado en ella.

While the news is disappointing, its not at all unexpected. The worlds largest manufacturers are dealing with the same issues. From a global economics perspective its fascinating how the “just in time” supply chain is unable to adapt to meet demand.

It might be time to make global moves to shorten supply chains and not be dependent on suppliers half a world away.

This is honestly really disappointing news. Why open preorders with a shipping date before design is finalized and sourcing has started? Should know better in these times.

Disappointing how? From day 1, they’ve been totally transparent about the fact that the design was not finalized and that they expected to have sourcing issues. That’s why pre-orders were a fully refundable $200 for a machine that will cost at least 10x that.

Right?!! Thats the whole point of pre-orders lol they have a prototype to market and then use the pre-orders to get an idea of production volume needed then source the parts to fulfill said volume. The one thing I appreciate and is why I love prusa products is that they are not just sitting around waiting. They are actively trying to improve it while waiting on supply.

I don’t understand how people can be mad. Especially knowing the supply chain issues. Hell even Apple can’t get the parts they need. If one of the biggest companies in the world can’t get parts I can’t imagine the lengths a small little outfit like prusa have to go through to source parts!!!

I agree 100% that delays were not only possible, but to be expected, and that’s not what’s getting my goat. As I’ve always said, Prusa’s deal is a good one, with a get out clause for anyone who isn’t happy. But, I did expect, as part of the deal, to be kept informed of the process; surely, that isn’t too much to ask, if Prusa has asked us to be financially invested at such an early stage? Once every four months really isn’t good enough, especially when we are promised more. There must be things we could be told by now, and keeping it from us just smacks of disdain for excited and loyal customers. Are finished units still going to be delivered next month. I have absolutely no idea at this stage, and there is no reason not to let us know. If not, which is completely understandable given the state of the supply chain, they should let us know that things are worse than they expected. If they are, then they should have a clearer idea of the specs at this late stage. I for one and I suspect many others, would love to know, even if we will not be getting our machines for a year. Poor, poor show, Prusa. I feel like I’m being ignored.

Thank you, for the new dev diary on the XL. As I’ve said, I’m not only fine with the delays, I fully expected them, what with the world as crazy as it is right now, and with a war on your doorstep. While I’d have hoped for a firmer idea of what specs were expected, I fully understand why you’re not able to provide them. By far the most important thing, to me at least, is the promise of more regular updates. Please, please keep this promise; as if you don’t, it feels like you are ignoring your customers. Once a month would be nice, even if all you can say is that supply problems are getting worse. I think this is doable, right? You must have known some time ago that you’d have to ditch the cycloidal extruder, and that you probably wouldn’t be able to meet your intended targets. I think it’s a matter of respect to your customers, to let us know, rather than tell us a lie of omission.

Thank you for the update. I am a December preorder and fully expected these delays at well. Not because of the past performance of preorders with Prusa. Companies can improve just as people can. Anyone who thought everything would go smooth with development of this printer along with the problems happening on the world stage must live inside of a rainbow. Keep chugging along and updating us. I have a 5 head on order and was excited for the Nextruder I understand the reason for change to the new planetary set up. Thank you for the long awaited update! Please don’t wait so long for the next one. I also really hope for an actively temp controlled enclosure as I want to print Nylon and other filaments that would do better than my current enclosure on the MK3S+. Thanks Again, Z

Thanks for giving us a detailed update 😀

I feel your pain with component sourcing, my advice is to have a look on https://www.netcomponents.com/ (it’s a distributor/OEM database for “excess” stock, which these days are the difficult to source components)

Regarding the ACDC PSU (single 1kW unit with many rails, or single ACDC and 2 DCDCs), I suggest going with the latter. As I guarantee it will be much easier to find an alternative for individual PSUs than it would be for a single on that does multiple rail outputs (especially if there are particular functions/standards you need the PSU to have/meet)

I agree with Antalife about using multiple PSUs. They will be cheaper and easier to get.

And plug into to separate outlets or even circuits in the house.

I’d rather have 1 PSU for exactly that reason. Already have two other printers, plus light systems, plus Octoprint rigs in that room. On top of that I have my computer, normal printer, two monitors, speakers, and smart speaker hooked up. I don’t have enough room for another 4-5 outlets for my third printer’s multiple PSUs, lights, and Pi.

Thanks for the update. Most rational people understand the way the world is working these days. Easy enough to back out if not. Happy to continue using my current Prusa’s and wait patiently for the XL. (Maybe even pick up a few more current models in the meantime!)

Keep up the good work, and keep the updates coming!

Thanks for the update! Supply chain for electronics especially is hard right now, I get it. That is crazy that some suppliers are trying to scam with clones.

One question I had was will there be a larger 0.6mm nozzle on the XL by default? It seems like that is the way to go even on MK3S with the new Arachne perimeters.

For the XL heck I would even try 1-1.2mm nozzles for that extra speed!

Thanks for the update. We understand the various obstacles due to the current situation with the various crises going around. What we needed and need are regular updates to keep us in the loop even if the timetable is moved further down the road. We prefer a functional printer up to mk3 standards even if it takes longer than quicker delivery and a mediocre beta version printer that need constant fixing.

Just glad to read a dev diary. This just gives me more time to decide if i want the big chungus full tool changer setup, save up the money, and see how its going to fit with my current printers. Also glad to read that prusa is keeping strict to its quality.

Yay.

I completely understand that Prusa3D has problems with the shortage of quality components (our company, although buying components like maniacs already since March 2020 (an intelligent move) now is forced to stop producing first variants of our product).

But still this is really bad news. I am a day 3 pre-order guy, which now probably means that I would be lucky to get my unit before the end of 2023. My custom 3D printer, in use since 2015, finally irreparably died a few weeks ago and now I need to fill the gap with some throw-away printer of the 200€ class and can hope that this thing will work at least one year (these Chinese products unfortunately did prove some prejudices to be to be no prejudices at all). Of course I could buy the Mini+ (kind of a strange idea, buy one device from a company to solely wait for another device of the same company to be delivered due to delays in production), but I just checked, the kit version now costs 459€, I recall to see a price <400€ for that just a few months back. This is really a lot of money for a fillerdevice -.-

May we live in interesting times…

P.S.: I unfortunately postet this post just a few moments ago in the other blog entry of the "first look" by accident, sorry for that…

I originally wanted an XL but switched to a MK3S+. I reordered one recently however. All the more keen since my experience with MMU2 is heart breaking. The XL approach is so much better.

If you are having so much trouble getting STM 32 may I ask if you considered the SAMD51J from Microchip. ? It’s a low power MCU but has lots of neat features including 70 odd I/o lines and 8 serial ports and a large memory map.

Thank you for the update. The delays will not come as a surprise to anyone who knows anything about the semiconductor industry. The decision to pivot away from a 20:1 non-backlashing cycloidal gearbox to a 10:1 backlashing planetary gearbox is a bit of a bummer, but results are ultimately the only thing that matter– if they’re good, then I really could not care less what type of gearbox it has.

Hello Joe!

Thanks for the update. The delay is not a problem, development is a long journey, remember the history of Prusa Mendel ;)! It is really nice that we go the way together (Prusa team aktiv, we passiv).

Thanks that you all spend your energy for 3D printing!

Just wondering. Any reason why there is no “extra” part cooling solution, with the same purpose as on the Bambu Lab to achieve better speed/quality ?

It makes layer adhesion and mechanical properties of most materials pretty bad. You can print a benchy quite fast this way, but not a practical thing like a hanger.

At the earliest time, Prusa should re-institute the online listing of order numbers and anticipated ship dates. That was very helpful in the past with the Mini? Or was it the Mk3? It is clear that no one is ‘jumping the line’ and we can see the progress and even predict how things will go

you can see the purge tower on the last GIF with the multi color lama print.

wrong reply^^ sorry

Sourcing parts may become even more difficult in the very near future. Just sayin’.

Still no update on the display. Would be nice to see a similar one as the touch screen of SLS

Still no update on the display. Would be nice to see a similar one as the touch screen of SL1S speed

The world is chaotic in the production sense with electrical components, metals and such . Cant say how much I’m looking forward to this product when it’s released !! A few months delay now a days is normal , I work in the automotive sector as well and there’s thousands of parts on manufacturing delays right now so it’s world wide . Can wait to see how this turns out guys , keep up the good work !!

If day 1 orders are 6 months, what does that mean for those even a few weeks out? It would be helpful to update the pre-order page. Maybe pre-orders should stop until the situation improves.

I also do electroning development. And in the moment we do change most of our produrcts to get them working wit STM32 chips that are available. We are waiting over a year for the delivery of out standard STM32. And most other components are also hard to get. Since no one knows wich components are availebla soon, ist very hard to choose the right for the new products.

I would like to see to get the XL this year. But i know that the suplyment is a critical part. So hope you find a solution for this.

Keep up the struggle! Even though this (the delay) is disappointing to hear, I trust Prusa3D’s best efforts and will also keep patiently waiting for my XL.

Please change the dates on your pre-order sales page for the XL, as it is still showing Q3 2022. I’m sure you don’t want to mislead new customers.

Good things come to those who wait!

this are very bad news …. waiting for two years if you are not a first day preorder IS not convenient .. can you guarantee at least the price ?

Thanks for the update. I wish it was better news about the delivery time but I understand the current estate of affairs and I am hopeful to see you have kept on improving the XL its reliability, speed, and much more.

However, if I may. I think an approximate timeline for the preorders is needed. You speak of 6 months for day 1. But what if you ordered it on day 2? 6 months + 1 day? or maybe 1 more month? What are we talking about? How much do you guesstimate it will take you to produce 1 day of orders (more or less)

Maybe if our order page showed a GUESSTIMATED time… That will allow us to make plans accordingly. And calm down nerves in the process.

Thanks again for your work!

SM Digital Solution is the Best digital marketing company in India

that provide advanced digital marketing services. we are also a best digital marketing company in Gurgaon.

we have dedicated team of expert in the all the module of digital marketing. we provide SEO services, PPC services,

content marketing services, social media management & Email marketing for every types of business. sm digital solution is a one of best digital marketing company in India.

In regards to sourcing issues. At my company, we have a sizable team working on sourcing (our needs are in the millions), but we are also able to leverage sourcing teams at our contract manufacturers. This has been key for us.

By doing your own FATP (final assembly, test and pack) you have more control over production, but you lose the ability to have a contract manufacturer working with you on finding hard to get parts (this is where having partners in China can help too, and they can check local distributors and excess inventory resellers.

Our situation is likely a little different from yours, as our volumes mean we normally buy direct from manufacturers, rather than going to distributors. This means we can attempt to negotiate directly (getting our execs on a Zoom meeting with their execs type of thing), and only are using distributors as a means to fill in when those commitments fall short.

Despite all our efforts, there are some parts than simply cannot be found at any price right now (with >52 weeks leadtimes). Ti is particularly bad. In some cases, we have had to qualify second source parts (for items like LDOs, etc.). In other cases, we’ve had to redesign to eliminate the ultra-long leadtime components.

If you’re using Ti Hall sensors, have you looked at changing to Rohm?

we are working with top VIP models “Escorts Girls in Gurugram/Delhi/Noida call us +91-9818604831 for the booking Model available for your entertainment in Gurugram/Delhi/ Noida and here deals VIP, High-profile, Indian Escorts and Russian Escorts girls.Delhi Russian Escorts

We guarantee that if you have hired our Russian escorts in Delhi, Gurugram, Noida or Faridabad formerly, also you’ll return to us again. Our Escort Models work in private apartments and Hotels. They all belong to a healthy- admired family. Utmost do not reveal their faces on the website. Aerocity Russian Escorts

I am thrilled to hear about the work being put into the firmware. I have a small print farm and one of the standout features of my Prusa MK3S+ machines is how intelligent the firmware is written. The hardware is great but there is some solid Chinese export competitors these days, what remains especially noticeable to someone printing everyday is the user considerations Prusa takes with the firmware. I obviously would like the XL to already be here, but the delays in supplies is global and across many industries. I work with neoprene materials and we have faced similar delays of months for items that previously could be sent within weeks. Looking forward to being able to pay the rest of my deposit, thanks for putting so much thought and effort into your products Prusa Team!

Will we be able to buy more print heads down the road? I.e. Order the 1 or 2 print head version now and buy the other print heads as we want / need?

Hi Mark42Customs, I think that has already been stated, when shipping starts I believe your notification (payment request) will offer you add-ons and upgrades.

I ordered a single head and then thought two would be better (no pun intended) and I think the XL enclosure will be offered at shipping time too.

I did try to edit my order to include the second head but the cart seemed to want me to order another printer not amend my current order.

Thanks for the report, although it was like ‘No my printer won’t be here until next year!’ it’s still great to read about how things are going, it boosts the anticipation, reassures us we will get a quality product and most importantly lets us know we are not forgotten and that you ‘haven’t run off with the money’. ☺️

Looking forward to the next update, and good luck finding the parts.

As a manufacturer myself, I feel your pain, and I share your sourcing woes. In fact, until I read your post I never thought about the fact that my vendors might be competing for the same batches of parts, but now that I think back I’m sure that’s the case. In fact, one reseller who couldn’t fulfill an order accused ME of having already bought the parts I ordered from him!

But I’m very happy with the upgrades you are making to the software, sensors, motors, and enclosure. I know you bill the goal as being simple and convenient (which is very hard to accomplish), but this looks to be a fine machine indeed.

Thank you for the full transparency on the challenges, etc! While it’s super disappointing and frustrating to wait a bit longer for the awesome new printer, it has to be a lot more frustrated to have a mountain of orders and no way to ship products and collect money!

Anyway, this sort of direct candor really helps to build trust and is very much appreciated!

Thanks for the update on the XL. What I’m looking forward to is the next update on PrusaConnect and the Mini+. Would really like to be able to use the ethernet port on the mini and no longer require a Raspberry Pi (which are also difficult to source these days) to remote print. Is development still continuing on these past promises?

Maybe I missed it but will the XL have the ability to load print files over WiFi?

So the only negative thing I’ll say is: It’s about time you put out an update!

Otherwise, totally understand the wait and issues, I’m not all that concerned personally. Actually, works out better for me and my finances to push it to Dec, or even Jan or Feb before I actually have to put the rest of the money down. And it’s great to hear you’re actually pushing the firmware and design even further!

I’ll have to really start finding more uses to print with such a better quality and bigger print bed! And I’ll have to really invest in building a proper dry box and a good enclosure, to stash it somewhere accessible, somewhat out of the way, and quiet it down somewhat.

Thank you for the update on XL project, I hope your supply procurement problems start to improve. I know that this problem is very hard to deal with. I work in the electrical and control sector and we are suffering the same issues. With 1 year lead-times on comports that is before you can make something. Hang in there, still excited and looking forward to receiving this great printer when you get into production. Best regards to whole Prussia team. Mitch

Really excited for this and so appreciate the attention to detail you guys are taking. The supply issues are a bummer but everyone is dealing with them so I definitely understand your frustrations. Hang in there team! You are doing amazing work and this is going to be one hell of a product that is a game changer for the industry! Can’t wait to see it in production and have one on my bench.

Keep up the awesome work to the whole team!

-Brian

Sorry that you’re running into supply chain and quality issues. I really love the ideas you’re having, and once the supply issue is resolved (most likely years from now) I would definitely be interested. I do hope that some of the ideas and concepts here, like the tool changer, will make it to the “older” type printers. I’ve really wanted to make my Prusa printer able to easily change nozzles and materials.

Keep on innovating and thanks for the update.

I’m still pressuring for a XL display to match. A nice big beautiful color touchscreen display. That tiny one originally debuted is dated and should brought current with the times. Honestly a printer of this one should be able to see the display info from across the room. I do have to be honest, I was looking forward to the cycloidal gearboxes which was a major key in purchasing. 👍

I’m still pressuring for a XL display to match. A nice big beautiful color touchscreen display. That tiny one originally debuted is dated and should be brought current with the times. Honestly a printer of this size, one should be able to see the display info from across the room.

I do have to be honest though, I was really looking forward to the cycloidal gearboxes which was a major key in my purchasing decision. 👍

Suits me well since I’m broke now anyway

The most important detail IMO is the time that it takes to change heads, and if it requires a purge block. My expectation is to be able to change color or material under 4 second at the very least, but 2 seconds would be exceptional!

For example, say I want to print a RC tire with a PLA rim but a TPU contact surface. Another idea is to design hybrid RC car/plane frames with a strong filament for skeleton but lightweight and cheaper touch surfaces, all in one go. If it’s going to be slow at that then more affordable printers are in order.

However, I also note the development team is on the right track since they are hinting at input shaping. Ringing sucks, so the accelerator on the head should allow Prusa to tune it out quite well. The article also mentioned running Klipper, but I would love an all Prusa solution.

I am quite excited to know more. Hard to justify $3500 without a bit of assurance.

Prusa need to speed up. Until you start to send the XL, Bumbo lab will have 2’d generation macine (larger with fixing bugs)

Flashfrog , and all the chines companys not wait for Prusa and the will have remarkeble machines.

Prusa going to lose the Market!!

It’s always fun to read when someone is discussing what is obviously a labor of love. Hope this world gets back on track soon, so we can see the end result in action.

“More info soon”…

“The next on comes much faster”…

Really?

No.

As far as I can tell, there has been no new info ont the XL since august 5. 2022.

I would settle for even the most basic and trivial status-reports every two weeks or so – but no, nothing but crickets.

It’s not like I want you to rush the building process – the XL will be ready, when it is ready – but the silence is killing me!

Good Point !

I understand about the delays. It’s a rocky path you must follow to bring a new product to market amid continuing variance in component availability.

And the images you’ve included lend credence and encourage continued patience in those who have committed to eventual purchase.

Do you think that the enclosure that’s mentioned will be included with the printer or an added extra ? It’s the market trend to include it ( eg. Snapmaker Craftsman model). It would be great if it’s compatible to sit beneath the current enclosure albeit larger footprint.

So this update was issued in August, ‘2022 perhaps it’s reasonable to expect another update soon ? It would be nice to see a roadmap (diagram) on how you plan to proceed toward production and release even if the time frame must be imprecise.

In terms of testing did you consider involving qualified and experienced users in the testing program ? It could provide valuable feedback in the event that it’s unclear what path to follow and if there are any unwanted glitches or unexpected behaviors that might appear in real world conditions.

Hello PRUSA team !

I made a preorder of a PRUSA XL in February 2022, could you please confirm I will receive it during December ?

Because it’s for professional use and my society works with annual budget allocation and we would like to buy it on the budget of 2022.

Tkanks,

Simon

Would love to know about safety features. I feel this has been a differentiator (for me) on the i3, so I’m curious what the XL had in store.

Two more months and no update. I would assume at this point that we are looking at Q3 of 2023 being the best-case scenario. I wonder how many people have given up on them.

I definitely can understand the difficulty and stress that can come from unexpected component problems, whether with sourcing or technical issues with the parts themselves.

The stuff you’re working on is absolutely outstanding to say the very least and I really want to thank you for your outstanding efforts so far. You’re putting time, faith, blood, sweat, and tears into developing something that has the potential to directly improve and advance the future of humanity as a whole – not for praise or notoriety, but for the sake of progress.

The kind of work that the world relies on to continue moving onward.

Thank you.

I have little to offer beyond my enthusiasm and my time, but I am happy to offer what I can nonetheless.

If by chance there are materials you need that I can help supply, or if there’s anything I may be able to do that can contribute to your work, I would be more than happy to help out!

If by some crazy chance there’s ever something I can do, just let me know – I’m always happy to take on a new project!

Keep working on it until it is of the quality Prusa is famous for. I always work with ASA, Nylon, or Polycarbonate type plastics, this printer needs to be enclosed with constant temperature control. Looking forward to it.

I have a question. With there likely being long delays, and with world-wide inflation going through the roof, are Prusa going to honour the price of the XL as of the time people pre-ordered? Also, I’m in the UK, so will be buying in GBP which has lost 16% of it’s value against the USD. Will the GBP (or other currencies for that matter) change from that which I was quoted?

Maybe not feasible , but could you solve some supplier issues by setting up new production lines or new suppliers using preorder funding?

For example – Offering all preorder customers to pay an additional 50% of the product price. Then using some of that funding to completely set up new production lines somewhere or somehow funding the start up of a new supplier or materials source?

I realize there is a lot to dig into there.. maybe doesn’t make sense for a lot of reasons, but if it is a possibility, I wouldn’t mind paying more of the total if it helps speed things up for us all.

So, apparently 4 months between updates is far too long, and we were promised them far more frequently. But 3 months since the last one, and still I have no idea if Prusa will update us anytime soon. And I’m not buying the “we’ve nothing to say, so, it’s not worth putting out an update” either. I’m not looking for War and Peace, just a current overview of progress, or even lack thereof. Last we heard, Prusa were going to ship a few units next month. Are they still on course to do so? Either way, that’s news and something worth sharing. And if they are, there must be a wealth of info on what the final unit will look like, specs, and even the final extruder design.

Shouldn’t the updates to the XL come more frequently now? Again, nothing has been heard for over 3 months. Pre-orderers, who have even already paid money, are really neglected. No matter how the global situation is currently and how much things are delayed, you as the company Prusa are solely responsible for your communication and that is terrible in this whole project …

It would be nice just to have heads up on if December is looking good.

I ordered in February so not even sure if I’m in the first batch to be shipped.

I did a dumb thing and gave away my old printer close to the original shipping date.

So Joseph? From February we have paid deposit. We are grateful to you for your commitment but two lines of information towards those who allow you to experiment (with their money) would not seem to ask me too much

I’m sure I have remedied … thanks

Concerned we’ve heard nothing as of late. Christmas is coming and I’m trying to figure out if I’m going to continue to wait or reclaim my deposit and go somewhere else. I love Prusa printers but this is starting to be worse than a kickstarter campaign.

I take issue with the statement “the mechanical properties of these super-fast prints are very poor”. What is your definition of Super-fast prints?

I have a Voron that runs 400mm/s forthe standard print profile. With Petg I can get 70Mpa in the XY direction and 60MPa in the Z direction. That being said, my prints at 1,500mm/s certainly aren’t very strong🤣

So, the lastest update is 6 months old. I plunked down $500 preorder the day I got the original email announcing the machine. It would be nice to know when this thing will be shipping! 2nd half of 2023 is at least the 3rd delay I’m aware of. Cute comments and community “we’re all pulling together” aside, when will you start shipping these things?

I am a consumer of electronics components and familair with the supply chain issues we WERE all feeling. The difficulty getting parts (with the exception of vacuum tubes) is pretty much over for the most part. There is growing doubt in the minds of people I talk to that your supply chain issues are real any longer.

We are beginning to be skeptical this is strictly a “sourcing” issue. It is starting to feel more like the product doesn’t deliver reliably yet. The re-designs and re-engineering are being swept under the covid/supply chain issues rug.

Maybe you should ask the Raspberry Pi buyers how/where they are getting their stuff:

https://www.phoronix.com/news/Raspberry-Pi-Recovering-In-2023#:~:text=The%20Raspberry%20Pi%20single%20board,prices%20by%20some%20online%20retailers.

How about another update without all the noise. Stick to the facts so we can decide if Prusa is still worth the wait.

The shipping page on this website states “Shipping is scheduled for January/February 2023”. Has anyone here received an XL yet? I have not noticed any videos online with people receiving it and reviewing it which seems strange given the shipping schedule, so thought I’d ask

Competitor analysis is the cornerstone of strategic marketing, and this review is a treasure trove of information. The <a href="https://www.linkedin.com/pulse/best-competitor-analysis-tools-review-2023-valerii-khomenko/">competitor analysis tools</a> mentioned are versatile, providing deep insights into the competition. As a marketing professional, this review is my go-to resource for staying ahead in the game.