After several years of development, complicated by the pandemic, disrupted supply chains, and war in Europe, we announced our new Original Prusa MK4 today. We began shipping the first units of the XL two weeks ago. There is an upcoming PrusaSlicer 2.6 with organic supports and many other great features. Our firmware team is finalizing the custom implementation of input shaping (vibration suppression) for the MK4 and XL. In addition, there’s the new MMU3, with completely rewritten firmware and tons of improvements.

The above and many other things we’ve been doing at Prusa Research for over ten years were only possible thanks to the great 3D printing community and open-source philosophy. However, the new printers and software releases have made me think again about the current state of open source in the 3D printing world. How sustainable it is, how our competitors deal with it, what it brings to the community, and what troubles us as developers. Consider this article as a call for discussion – as a kick-off that will (hopefully) open up a new perspective on the connection between open-source licensing, consumer hardware, and software development.

Before I start, I want to make a few things clear to avoid any misunderstandings:

- We stand by our roots in open-source and will continue to do so.

- Our desktop 3D printers will always be open source. We intend to continue publishing plastic parts, along with firmware source codes.

- We will stay open to third-party component manufacturers, accessories, add-ons, and unofficial upgrades.

- PrusaSlicer will always be open source.

- Our investment in PrusaSlicer and firmware development will continue at the same or higher level.

During the last decade, I have always been against companies that have turned away from the open-source community as time went by, eventually becoming closed-source. I don’t want Prusa Research to go in the same direction. Patents by big companies have limited the 3D printing world from the beginning, and projects like RepRap have helped it break out of that grip. When several important Stratasys patents expired in 2014, open-source development could finally take off at full speed.

Anyone developing something related to 3D printing today will benefit from more than ten years of continuous open-source development. Hundreds of individuals and dozens of companies contributed to getting the industry where it is today. The idea that you can develop a 3D printer with its firmware and software from scratch in a year or two is an illusion. We will always stand on the shoulders of people like Adrian Bowyer (founder of the RepRap), Alessandro Ranellucci (original author of Slic3r), David Braam (original author of Cura), Scott Lahteine (Marlin maintainer) , and many others. At the very least, they all deserve public recognition and thanks whenever someone uses their work. And that brings us to what worries me.

The open-source movement relies on the fact that everyone involved plays by the same rules. It cannot be done without mutual respect, understanding, and a shared goal. When someone suddenly bends the rules for their own benefit or openly violates them, the community makes it clear that it won’t stand for it. In the past, we’ve seen plenty of protests and boycotts that have forced even large companies to rethink how they treat open-source heritage. But in recent years, I feel that the situation is changing. More and more companies are breaking and bending the rules, and the community is not nearly as resistant to their actions as it once was. After a minor internet storm, the situation calms down, and the code remains closed (or only part of it is opened), and after a few weeks, everyone forgets.

In the meantime, I’ve been receiving information about companies that have started to apply for local patents based on open-source development and trademarks (you’d be surprised how many of them have “Prusa” in their name). About companies partially owned by state companies and institutions and using open-source code in their closed systems, thus violating licenses.

Of course, not all open-source violations can be proven easily, but if you look at history, you will find that it would not be the first time something similar has happened. One example for all is solar panels – the original inventions and processes were gradually copied by Chinese companies. After that, with the help of state subsidies and tax breaks, they drove all competition out of the market within a few years. Today, you have virtually no chance of buying a non-Chinese-made solar panel.

I hope this will not happen in the world of 3D printing. But the truth is, we might be the last big 3D printing company that fully adheres to open-source principles. And I’d really like it if there were more of us.

We’ve spent years on open-source development, whether contributing to the original repositories or later in our own hardware, firmware, and slicer forks. Our internal PrusaSlicer team has 13 people, and the firmware team has 21 – that’s hundreds of thousands of man-hours of work only over the past five years.

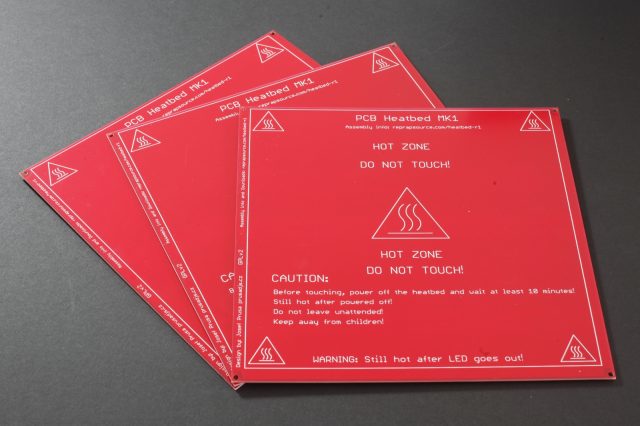

Since my brother and I started with 3D printing, we have (along with our colleagues later) come up with a whole range of contributions that you can find on almost every home 3D printer today (open-source or not). Whether it’s a PCB heatbed, removable print sheets, powder-coated PEI applied directly to metal, automatic mesh bed leveling using an inductive probe, power panic, advanced thermal runaway protection, automatic skew axis calibration, sensorless homing, and much more – I would never consider patenting any of these contributions and not sharing them with the 3D printing community.

One of our first heated beds

And that’s just stuff related to firmware and printers. Besides that, PrusaSlicer has undergone so many changes that the original Alessandro’s Slic3r is practically invisible underneath all of the new additions (and yet we continue to highlight Slic3r’s heritage in the main bar and elsewhere). By the way, take a look at the documentation of PrusaSlicer on our website or our fresh Twitter account, where you’ll find useful tips and tricks!

PrusaSlicer is a great example of what open source can bring, but it also demonstrates some of the risks I haven’t mentioned yet. A positive example is the incorporation of amazing community contributions such as adaptive cubic infill or tree supports, which you will see soon in PrusaSlicer 2.6.0 in the form of organic supports. The collaboration with the team behind Cura is also great. We have got the Arachne perimeter generator and Lightning infill from Cura, and we returned the favor with, for example, a monotone infill or the bed management system.

Want an early preview of the Organic supports that are coming in PrusaSlicer 2.6? We’ve pre-sliced a couple of G-codes for the MK3, so you can try them out! If you print any of them, we’d love to see how it turned out or even a video of the removal of supports. 🙂 pic.twitter.com/sQAh1xTDWO

— Prusa3D by Josef Prusa (@Prusa3D) December 7, 2022

Unfortunately, there is a downside. Taking over features between competing slicers only makes sense if the contributions of the individual parties are at least partially balanced and if the authors are quoted correctly. And this is not always the case.

And then there are the community contributions. Due to the popularity of PrusaSlicer, many people contribute their pull requests on GitHub, expecting their code to be automatically added to the main branch. However, PrusaSlicer has become a highly complex program over the years, and similar contributions are usually “one-trick ponies” – they solve a problem that bothers a particular user. Still, at the same time, they break other features. Our developers must optimize, modify, or even completely rewrite most of the external code to keep everything stable and reliable. We constantly refactor large parts of the original code in PrusaSlicer, and keeping everything in stable is not easy. If you want to hear more on this topic, check out the presentation by Vojta Bubnik (PrusaSlicer lead developer), which he prepared for our special event at CERN – presentation starts at 00:25).

I don’t want it to sound like I’m complaining about the community’s involvement in development – on the contrary, we’re grateful for all external contributions. But community development isn’t the main reason why we offer our products as open source.

Our main goal has always been to make our printers easy to maintain and modify, so people and companies can play and experiment with software and hardware. We’re thrilled to see the amazing modifications and third-party add-ons for our 3D printers (one nice example is here)! And one of the best things to see, and one of our greatest motivations, is when parents build a 3D printer assembly kit with their kids, thus gradually learning how the machine works.

Cool upgrade for our printers prepared by the team in ZHAW Institute of Mechatronic Systems

But getting back to the topic – what don’t we like about the current state of open-source development in the 3D printing field? To make it clear, I’ll summarize it into a few key points:

- The standard GNU GPL license under which our printers and software are available is very vague, written in a complicated way, and open to various interpretations. It was developed by academics for academic purposes. The 3D printing community has begun to use it for hardware for which it is not entirely suitable. A violation of this license can be enforced under copyright law, but these regulations differ in each country, and potential disputes can be long and expensive.

- In the current market for 3D printers and the software around them, many companies interpret open-source licenses in their way. They often do not release source code or only release parts of it, and only after the community puts them under pressure.

- There are 1:1 clones of hardware or software on the market that do not bring anything back to the community.

- When code is taken over, copyright headers and development history logs are often deleted from repositories, erasing any trace of the original code’s authors.

- Devices or software manufacturers who use open source do not give enough credit to the original authors. In their welcome screens, readme files, or websites, you will often find no information about the origins of the product.

- Contributions to shared repositories are not equal – in other words, some parties take improvements from others but do not contribute themselves.

- It is suspected that new commercial projects are being created based on open-source projects. However, their code is closed, and they apply for local patents that can eventually be expanded globally.

All of these points also imply possible corrective actions. The question is, how to achieve them while still remaining open source and supporting the community? Some time ago, I started thinking about a new license to address these issues more clearly. So I put together a few working points that I would like to see in such a license:

- If you’re using some code or blueprints to bring software or hardware to market, the original code’s authorship must be clearly stated on the product or in the software. Additionally, deleting copyright information from headers and history from repositories is prohibited.

- The production of nearly exact 1:1 clones for commercial purposes is not allowed.

- License for manufacturing spare parts is valid for service, modification, or educational purposes.

- Upgrades and additional modifications based on original parts are allowed and welcome.

- Parts that can be considered consumables (e.g., thermistors, heater blocks, fans, printing plates, etc.) can be manufactured and sold commercially after the verification by the licensor based on the presentation of samples.

- If a product is labeled by the manufacturer as obsolete (or cannot be purchased or ordered for longer than 3 months), the non-commercial clause is automatically terminated if identical parts are no longer produced within the successor of the product or cannot be purchased separately.

- If the licensor ceases its activity, the non-commercial clause is terminated.

Right now, with the release of MK4, we will make available models of all plastic parts and firmware sources (they are already out since the release of the first XL firmware). However, due to the current state of the electronic components market and also the issues outlined above, we will not rush to release the electronics plans just yet. We would like to release them already under the new license.

Basically, what I would like to do with this article is to start a discussion. I want to hear what you think about this, and I’d like to include prominent figures from the open source fields, Youtube personalities, journalists, and other 3D printing and open-source hardware companies in the talks. If we can all agree that the current situation is not ideal, let’s work together to improve it.

At the end of the day, a new license will not really solve the problems.

But I’ve actually thought about this a few times already, and here’s 2 options:

Option 1: An open source hardware/software alliance with other companies that throws lawyers at companies that violate licenses. Extremely expensive and may greatly affect the image of involved companies.

Option 2: Start a massive push to legislate open source hardware, software and knowledge on the EU level. The EU is about as pro consumer, pro right to repair as it gets for a bloc its size. Being able to impose something like import or sale restrictions on misused EU-designed software/hardware is a fairly sound argument to make.

Your open source commitments are honestly kind of surprising. But at the end of the day, you can do that – even if it indirectly causes you losses – because Prusa is still privately owned. I hope, for the sake of the 3D printing community as a whole, you keep it that way for the foreseeable future.

I haven’t been in 3D printing since the start, but I’ve come to greatly appreciate the long term commitments. Not that my experience has been flawless in every way of course, especially from day 1, but the long term commitment to supporting a product is something I want to make more common, and it’s something I wish to support.

You probably know better than anyone else that it’s not gonna be easy sticking by principles, but I wish you guys the best of luck.

Do you really live the dream of EU protecting small from big? If this goes to EU level, it would kill as much as possible. There is no free trade, no free speech, so free software is just hiding in the corner now and it should stay that way – if we want to have it ofc.

I’m not a big fan of EU but it’s currently forcing Apple to use standard USB-C without any tricks etc. So how is it protecting big?

I find it interesting when you mention that not enough credit is given to the original developers, but somehow only take your point of view on the matter.

While I am not a fan of closed source and wholeheartedly agree that open source licenses should be respected and the correct credit should be given, fact is that the MK3 and its iterations were heavily inspired (dare I say copied) by modifications made by the community that address certain issues with the printer build/assembly. Issues that should’ve been addressed in the testing phase of the product development cycle.

Now you incorporate those same design ideas in your MK4 iteration, but I haven’t seen credits given to any member of the community. Are they too small to matter or is it that open source license violations are a problem when your profit margins are concerned? No wonder that your new idea for open source licenses is aimed at protecting Prusa IP, while “Upgrades and additional modifications based on original parts are allowed and welcome.”

It is indeed true that MK4 drew some inspiration from the community, but it’s worth noting that Prusa has proven themselves and have contributed more to the community than what they took. Therefore, I believe they deserve a fair pass for this.

And is a valid point the open source project has been misused frequently, let’s not lose sight of the more important question in this thread.

What is the more important question in this thread that you think I am missing? The lack of open source “rebellion” that Jo calls for “protecting open source” being stifled by the very same lack of interaction and credit to the community is not related to the “more important question”? I’m willing to bet that the majority of Prusa Research market share isn’t made of open source enthusiasts, and the ones that are, usually end up on the “sides”, flocking to projects like Voron and the likes, mostly because of the reasons I mentioned.

And why is the open source in a “crisis” in 2023? This situation isn’t exactly new, is it. Back in the day when I was trying to make my MK3 functional (pre-order bonus, you get to be a beta tester), there were 1:1 clones being sold all over the place, to the point I was outraged how people can do that and get away with it. There were no calls for arms up until the competition grew so much that it took a solid amount of PR market share. And for a good reason, the MK3 had outdated tech and troublesome build even when it launched (proof are the the suffixes on the MK3). The competition showed to the market that you can either make the product cheaper or better for comparable price and the market responded exactly as one would expect. The MK4 is what the MK3S(maybe +) should have been if they even slightly engaged with the community as most of the “upgrades” were available years ago, instead the early adopters (read MK3) were told, sorry tough luck, but we have an “upgrade kit” you can buy, at which point MK3S+ with the upgrade paths costs more than an XL.

Prusa has given a lot to the community and I am extremely grateful for that, and for that they get leniency, not a pass sorry. It is not as if they are a small indie company with tiny profits. Leniency as, pre-ordering products that have months of lead time, the MK3 product launch disaster, buying all the iterations of the MK3 upgrade path even though 0 incentive was given to the existing owners to buy one… I can go on.

So no, I didn’t lose sight of the more important question, I just didn’t take the statement “we need to act now” by Jo as gospel and start acting upon it. I was responding to Jo’s statement why isn’t the “open source” community jumping on board to defend Prusa Research profit margin now that the “company that should not be named in Prusa forums” is on the market

Even if you’re right (and you probably are), I think that you must understand that Prusa as a company is competing in a very harsh and chaotic business environment.

While being one of the largest firms in the world, there are still many other players targeting different segments of the market. Almost every day now I hear about another company that manufactures 3D printers or 3D printer parts and consumables.

I’m sure Josef doesn’t really want to deal with this new license, and if he could he would go even further and expand his company’s contribution to the community.

However, he also needs to make sure his company survives. He has a lot of responsibility for his company, employees and the community, and therefore he must do these things in order to protect them.

Like he said, if everybody played by the rules, we wouldn’t even be discussing this topic right now, but since there are many players who break them, he’s forced to act in order to keep his responsibility.

This state of 3D printing right now is similar to the state the smartphones market was about 10 years ago. I don’t want to see Prusa go the way Nokia, RIM (Blackberry), HTC or even LG has gone.

Disclaimer:

I’m not a Prusa customer because I currently cannot afford it (MK3 kits cost 50% more in my country…), I’m still using their slicer and their Printables platform with great joy.

Let me start with the statement that I do not want to see Prusa Research go out of business, they are a valuable player on the market and contributed a lot.

I do understand the business environment they are operating in, more than just in context of Prusa Research and 3d printers in general as I have my own experiences with cheap clones/subsidized manufacturers ruining a business model.

However, as I stated before, I do not think this situation developed recently and we are all caught off guard. It has been going on for quite a while but only recently it has become an issue with Prusa Research. It might have to do with the fact that they haven’t had a new product for years now and the competition woke them up. Prusa printers used to bring something new to the hobby/enthusiast market segment, nicely packaged with customer care and that’s how they stayed one step above copy clones, as someone else mentioned in this thread, cheap clones are problematic from a QA standpoint even if the designs were fully handed to them and usually people buy the clones because they cant afford the original which isn’t the target market for PR anyway.

The new proposed licenses would have the same effect as the previous ones, if someone decides to ignore one license, one will ignore the other. That leaves the ones that do respect the licenses even more restricted. I don’t think that restricting licenses is the way to go, rather being innovative and closely tied with the community and their feedback/contributions whether they are from individuals or companies, to bring an innovative and price/feature competitive product.

Also, not every manufacturer is out to copy their designs blindly, as such manufacturers (or more precisely the copied design) have a rather short life span. I see very good examples of manufacturers willing to cooperate with other open source projects (albeit smaller than PR) to bring their ideas to the market (Mellow and VZbot come in mind). So PR can extend their relationship with certain key players in different markets (countries), maybe even license them to produce the parts so it extends their reach, and I am willing to bet that most of the users that can afford the original, will skip the clone as it is not supported nearly as good as PR supports their products.

Ultimately, my comments are aimed at criticizing the way PR engages with the community and their feedback/contributions (most of them paying customers) and the reason (at least one of the reasons) why people aren’t rallying to defend PR against clones as they used to – paraphrasing Josef here. Most of the contributors I know, have moved on to other projects exactly because of this reason. The way things were/are now, someone submits a modification/improvement, it gets traction with the community but has zero official response (not even an automated response), only to find out that their new iteration (silently) addresses the very same problem, often with similar design choices which leaves a bad taste (to say the least). If you don’t believe me, check out their GitHub issues and compare it to the MK4 features. The MK4 could’ve been a reality years ago if the relations with the community were a bit better.

One more thing I forgot to add, Nokia and Blackberry did went away, but not because someone copied them and sold their product at a cheaper price, but rather that they didn’t embrace/were prepared the new wave hitting the market, touchscreen smartphones. Kinda apt for the point I am trying to make here.

As one of the CERN guys who watched the presentation you linked to in person: Happy to see us being mentioned there! 🙂

these are the only points I find controversial:

– The production of nearly exact 1:1 clones for commercial purposes is not allowed.

– License for manufacturing spare parts is valid for service, modification, or educational purposes.

– Parts that can be considered consumables (e.g., thermistors, heater blocks, fans, printing plates, etc.) can be manufactured and sold commercially after the verification by the licensor based on the presentation of samples.

i’m fairly certain the last two can be handled with an official vendor licensing program and more copyright enforcement on those who do not agree with them (to minimize the ability to market them as “prusa mk4 replacement parts”), i’m not sure 1 can be reconciled with the nature of an open source license and still call it open source. It will be certainly open and permissive licensing; but it wouldn’t fit the definition of open source.

I also find it hard to really quantify what a “near exact” clone is, I hope you get very precise in your definition since that would be a very broad category. certainly something like a printed part kit of something that literally advertises itself as a “Prusa MK3 kit” is a near exact clone, but would an ender 3 be a “near exact” clone because it also a bed slinger style printer?

O believe a lot of people conflate “open source” with “free to use”.

These two are very much separate concepts. This is even more so once hardware comes to the picture.

“Open source” literally means the blueprints are available for anyone to -see- and, thus, use AS A USER e.g. to upgrade/maintain/service HIS system/device so one is not beholden to the original manufacturer/vendor post-purchase. It has absolutely nothing about one’s “right” to build a business around those blueprints.

Check out some of Stallman’s talks on this subject.

I agree with 🐙🐙, some of this feels like moat building.

If someone has a better manufacturing process than you and can compete on cost, support, and quality, then I think it is valuable to have such a competitor in the space. Right now I don’t think anyone can compete with you on all of those fronts which is why I buy Prusa but I believe there is value in allowing competitors to keep you on your toes and innovating and providing quality. Once you build moats it becomes really easy to become complacent, often by accident, because you don’t have a clear market signal pushing you to constantly do better.

Requiring people to become “approved” to sell replacement parts just introduces a lot of bureaucracy into what should be a very simple process. Imagine some industrious individual in a small town/developing country who buys a Prusa and uses it to print replacement parts which they sell to other local makers at a local meetup. With the new license this person would be violating the terms of this agreement, and they likely don’t have the resources to get their parts certified. Over time they could grow their business and start selling online. I think this is the exact type of person we want to see more of in the world and licensing stuff like this is likely to hurt them far more than it will hurt some big Chinese knock-off manufacturer.

I think it would be better to focus on trademarks, and disallow people to use your branding without approval. Perhaps even have a clause that says you must mention that the part is “unofficial” or something if you reference any Prusa trademarks in your sales/marketing material.

If someone does not have to do research and development and can just take ready plans to make things – sure their process will be cheaper than one who had to create the stuff, even assemble the stuff if everything is done by the community. That is not the case with Prusa, who invests heavily in R&D, who invests heavily to implement all the user supplied stuff into PrusaSlicer. And even just maintaining that is a lot of work and resources. As Josef stated – to make all the software coherent and to make new features and fixes work with all the rest of the code base.

Lack of development saves the costs, ofc. But:

– it means you don’t get the experience, so you don’t understand what is important and what is not. You are unable to make a quick fix for suddenly unavailable part and so on.

– it means you can offer your product much later than original creator

Thus in the end, you offer a different product.

As a HW developer I would publish only simple schematics of individual interfaces (e.g. pinout connectors) and maximum block diagrams of the architecture. Everything else (detailed schematics and layout) is unnecessary and only makes the work of cynics with reverse engineering easier.

As a customer I would not buy that because it cannot be maintained, repaired or fixed if it is not quite up to snuff for my purposes. I want general purpose, well designed, modular, reliable stuff that uses commodity components or components I can get from many sources (printable is ok). Also companies that offer third party add ins or upgrades to mop up your inadequacies, which lets face it most stuff needs at least a few tweaks, will not invest to get products developed and out there unless the product is here to stay. When you know it has staying power, that leads to a secondary ecosystem.

Little black boxes, even if they have standardized interfaces, can become depended upon and supported, but only if the company is big and has staying power itself. Does yours?

Open source helps with a lot of things from the customer’s standpoint, if done well. Reverse engineer copyvio is probably not your biggest problem, in reality. I don’t even buy arduino clones on aliexpress any more because even when those guys are handed the complete design they still cannot do quality control. In reality, cloning is not the biggest problem.

However in my own business I am still not actually licensing the stuff for cloning. A competitor would be a bit foolish to set up a business around copyvio. It takes a lot of work aside from the engineering to make a business go.

How is life without a broadband modem? Or a functioning wifi module? The world is full of black boxes and we still buy them.

> PrusaSlicer has become a highly complex program over the years, and similar contributions are usually „one-trick ponies” – they solve a problem that bothers a particular user.

I would still appreciate some communication. I opened a small PR for PrusaSlicer 5 months ago fixing an issue, received many upvotes and comments wanting it to be merged, but no communication at all from Prusa. A comment on the PR would go a long way, even if it’s “it’s hard to incorporate this change due to internal work, we will get back to you in X months”, or “we already have a fix internally but it will get released later”, instead of leaving everyone hanging.

It’s understandable that reviewing external PRs is not that simple, but just ignoring them with no word doesn’t feel great.

I fully agree with your statement. I have similar experience with the design of the parted parts. You mention a potential problem, provide some ideas how to solve it, for all of that to fall on deaf ears or worse, they’ll make you go over a long list of beginner questions only to end up with the same non response in the end. What is even more troubling to me is that, those “one trick ponies” they (dismissively) mention, well, I cant say for the firmware side but I definitely have examples in the design of printed parts, where those “ponies” were silently implemented in the next iteration (with a bit of Prusa sauce so it isn’t a carbon copy) and touted as the next best thing that came out of Prusa.

I believe the “one trick ponies” referes to the specific pull requests. It does not mean the *idea* they represent is such.

There is a world of difference between “a working fix/improvement for the scenartio I encountered” and “a patch that addresses that scenarion *AND* does not break anything else”.

As for the non-response. Given the size of the team mentioned – barely 10 people – that would seem more of a bandwidth issue than anything. One will see very similar situation when contributing to Gnome or SystemD. Complex projects run by small teams tend to lack the bandwidth to reply to all contributions. Often it is also such that the software developers even lack the social skills for such. It can be infuriating, but I see this being more a norm than an exception on bigger open code bases.

A Pull Request out of the blue is a tough one. i would have thought there would have been an issue number and discussion of the solution AND THEN a supplied PR. Or are you saying the Prusa devs were missing from the issue and missing from commenting on your solution to the issue?

To me, it feels like open-source development is meant for shops of only two or three volunteers with a Big Idea they passionately work on after school and on weekends.

It does not sound like an industry business model for an industry that hopes to stay profitable.

Secondly, there are countries that show very little regard for patent laws, so what hope should we hold that those countries would respect a standard GNU GPL license?

That sounds so cynical … so it must be close to correct.

It’s definitely a valid business model; there are a ton of multi-million dollar corporations that survive off of open source software (which is what the GPL was written for). Applying it to hardware is a bit awkward though, which is what I think he’s getting at. Still, a CC derivative maybe or keeping it or parts of it proprietary for a while and then opening it up (so others can make replacement parts or mods/etc) still keeps most of the benefits there.

As far as the problems enforcing it go, even with changes I don’t think that is going to matter. That part is up to everyone else unfortunately, and quite a few countries don’t care or don’t have the same trade agreements to worry about. It’s always been a problem, and not likely to ever stop really.

Open source isn’t just for little companies, it’s fundamental for many huge companies too – basically any company that needs a software problem solved that doesn’t want to make money selling the software. Look for example at MySQL (mainly dev by Oracle) and Linux (mainly dev by IBM, Red Hat) or gcc (mainly dev by chip companies). They all benefit by the software solving a valuable problem for them, and it’s more efficient for them to contribute to a shared solution than to pay 100% of the costs to produce a proprietary solution. For example, Linux existing and running well on many hardware platforms as FOSS lets Red Hat sell support contracts, and lets IBM sell hardware, for example. And Oracle supports MySQL both as a low-end database option to counter MS SQL Server. And chip companies do the work of getting the gcc compiler to support their chips in order to allow developers to build software for their chips. So they have their own business reasons for doing the work, which is fine, the work gets done, and gets real resources.

If you’re looking for a new licence, your friends at CERN have the CERN-OHL.

That said if companies are already violating the GPL, how will a new licence fix that?

Unfortunately several of the points you suggest for a new licence would render it non open source.

Namely:

*The production of nearly exact 1:1 clones for commercial purposes is not allowed.

*License for manufacturing spare parts is valid for service, modification, or educational purposes.

*Parts that can be considered consumables (e.g., thermistors, heater blocks, fans, printing plates, etc.) can be manufactured and sold commercially after the verification by the licensor based on the presentation of samples.

If I am reading them right, these would all violate the open source hardware definition that you endorsed: https://freedomdefined.org/OSHW

I am just a casual Prusa customer, and the open-source aspect makes no difference to my purchase decisions. I make decisions based on the products and the company/individuals behind the products. If anything, I see the open-source aspect as a liability since another company can cause harm to Prusa, which will eventually impact me. You should give up on open-source; it will make no difference to your core business…

As the sector advances, as you push forward and make it more accessible, the user demographic is changing. What was once a relatively small community of intellectual nerds has now grown to attract something dangerous…. idiots, lots of idiots. That much larger market then attracts the eye of something even more dangerous, the cut throat, ruthless Chinese business man. They have resources no European company can match and more money than god because they have the backing of the state.

The new market full of idiots don’t care about licensing and if a company has stolen code or a design to make the shiny toy they’re buying. They just want to post timelapse’s so they get likes and shares and experience that little endorphin hit. After that they want to shout about metrics, the typical “mine is bigger than yours…mines faster than yours…mine has 10x yours only has 5x” etc. I’ve watched the same thing across several tech/hobby sectors for 30 years be it PC vs Mac (the 90’s were hard) Nikon vs Canon, Everyone vs Tesla etc etc.

The idiots are not going to understand and certainly not rise up and boycott those that don’t follow the rules. The only people that can apply pressure are those who have the audience of the idiots, the influencers. The problem is those influencers need to wake up before they find themselves at the mercy of a handful of companies in a race to the bottom.

I wouldn’t waste your time on altering licenses as I doubt it will have any effect, not unless you want to bankroll a plethora of lawyers across the globe. Probably best investing that money in fighting to make a better product and winning that way.

I’ve would’ve probably used a different word instead of idiots, but that is besides the point. I completely agree with your statement, particularly the one about bankrolling lawyers and that innovation and a price/feature competitive product is the best strategy against the clones.

I just recieved my MK3S+ in the mail 2 weeks ago directly from Prusa with no knoledge of the price drop coming or the release of the MK4. What is that?! I would have never purchased the MK3 S+ at 799 USD for the kit knowing the MK4 is coming out 2 weeks later at the same price and now the MK3 is 150 USD cheaper. The upgrade to 4 almost cost the same as theMK3 kit. What the hell Prusa?!? Im extremely frustrated by this! What is going to be done about that?

I am in a similar situation myself, but I find solace in the fact that the MK3S+ printer at least is truly free and open-source, while the MK4 (at least for now) is not. In fact, it might never be, if Průša chooses not to release the full source until either we all live in utopia and everybody shares equally, or a new restrictive license outlined in this article is in place. Notice how the outline allows manufacturing parts for “service, modification, or educational purposes”, but not, for example, for making new printers for the community for a fee covering the expenses, or even free of charge, in the spirit of RepRap.

Prusa is just starting a dialogue to try to figure out how to craft a license that keeps their designs open for the community and for people to contribute and improve designs, but to protect them from companies simply cloning the hardware at lower cost because they’re not doing any R&D. That’s a good goal, as the cloners drive a “race to the bottom” that ends up destroying the open source hardware industry because nobody can afford to invest in improving the state of the art as open source when cloners just copy everything and undercut them. It’s a complex balancing act, but the alternative, based on history, is for them to give up on open source hardware and go proprietary, which they’re trying not to do.

I am looking forward to see how the discussion evolves 🙂 At the time of writing, however, the MK4 is by definition closed-source.

And what would happen if you would buy new iphone week before launch of previous one? Prusa at least will give you voucher for pice difference. From FAQ of MK4 release:

Q: I just ordered an MK3S+ and the order is not yet fulfilled or shipped. Can I update it to MK4?

A: The easiest way is to cancel your MK3S+ order and make a new one for MK4. If your MK3 was shipped within the last month, you’ll receive a 150 USD voucher per kit and a 200 USD voucher per complete (so e.g., for an upgrade). You will get these vouchers by e-mail by the end of this week.

The new iPhone has a scheduled release date way before its launch date so the consumer has the choice to wait for the new one or get the old one. The MK4 was “scheduled” in rumors and podcasts only. Although I must admit, the vouchers do somewhat alleviate the problem.

To be fair man, if you bought a Nintendo switch and 2 weeks after nintendo announced the pro ? What should they do ? Always tell us where they’re on the development, that’s stupid, the only ones who can get away with that is apple, because they always reveal the new one at the same period as last time, and most of the time the changes aren’t that important.

But you can’t expect a company to just let you know 2 weeks before you buy, oh wait the new product is coming….

I’m an inventor on multiple patents that are owned by my former employer (big corporate entity for whom I still do occasional contract work). I believe patents still have their place, but that’s in increasingly shrinking space. I’m fully in favor of open source business models, like Prusa, but I can see the challenges that you face. Actually, they are very similar to the challenges that face companies who use a closed IP business strategy. The same countries that enable theft of open source designs without attribution are also running their own patent theft rings, disguised as their own official patent office. They grant patents that are direct copies of patents applied for or already granted in other countries, then restrict import of the products with the original patent, using their local bogus patent as the reason. The only honest business model that can succeed in that environment is one that continues to innovate to stay ahead of the dishonest competition. I think that applies to both IP-centric businesses & open-source businesses. Don’t discount that you might find allies in the IP-centric world, just because your business models are different.

Now, a little more discussion on patents, since that’s where my experience has been. I think there are some lessons to be learned here for any kind of open source licensing strategies. In 2013, the US became the last country to move to First-To-File patent rules (FTF). Before that, they were First-To-Invent (FTI). FTI required rigor to prove that not only was your invention novel, but that you were the first to invent it. That rigor tended to discourage frivolous patent applications. My patent filings were all under FTI rules in the US, but we were also filing in other regions that were already under FTF rules. What FTF did was to open the floodgates for entities with money to jam every conceivable idea into the patent office. The patent office, in response, became a rubber-stamp approval agency for nearly every crazy idea that could be formatted into a patent application.

The routine went like this:

Step 1: Patent applied for with initial fees & attorney expenses; the overworked patent examiner only spent enough time on each patent application to give it a first rejection for any reason, usually a bogus one that revealed that they didn’t understand the subject matter at a basic level, even for a well written patent.

Step 2: Patent applicant’s attorneys file an appeal; an easy task to refute the examiner’s error, but it costs the applicant additional filing fees plus attorney expenses. This results in a second rejection, usually without anymore logic or reason than the first.

Step 3: Patent applicant’s attorneys file a second appeal. On this third attempt, the patent examiner gives up & approves the patent, having collected 3 rounds of fees for very little meaningful work.

Step 4: Either sue or be sued. Since both you & your competitors are in a race to patent everything that could possibly give any advantage, & since the patent office is a revolving door for anything that fits on a patent form, it’s almost certain that the courts will need to sort it out in the case where one of those ideas starts to make money.

A very public example is smartphone companies patenting & suing over “gestures” used to execute certain tasks on touchscreens. Swipe this way for this & that way for that; one, two, three fingers, or the edge of your palm; pinch or anti-pinch. The courts in one jurisdiction decided one way, but in a second decided another way. Judgements were issued awarding retroactive royalties to the offended parties, then appeals were filed. In the end, the parties negotiated a final settlement outside of court, & both sides implemented the gestures. Now we can all swipe to our hearts’ content in whatever manner we see fit on whatever devices we prefer, & a significant part of our smart touchscreen price pays for the patent offices, courts, & lawyers fees all along the way.

I blame the magnitude of this debacle on the switch from FTI to FTF. FTI wasn’t perfect, but it was more even-handed than FTF. Once a few countries switched to FTF, many others followed to try to maintain their relevance. Then the rest fell like dominoes. The only winners are lawyers.

I believe in the viability of the open-source business model. I wish you well in your open-source licensing endeavors, & I’ll support in any way I can. I think it will need to be international in scope & should avoid legal recourse as much as possible. I’m open to continuing the discussion.

> The production of nearly exact 1:1 clones for commercial purposes is not allowed.

I don’t believe this restriction can be made with an open source license. (It would conflict with point 6 of the open source definition.)

So it seems like “open source” as a brand is in conflict with what you’d like to do, which is quite reasonable.

One solution might be to have some components use a different license, which could be quite permissive but shouldn’t be called “open source” to avoid watering down the term. Possibly, there could be a provision promising conversion to an open source license eventually.

See my comment above.

Open -Source- is NOT about rights to manufacture/sell copies. What you refer is an entirely different concept called “Free” Software/Hardware. Which, incidentally, does not have to be open source necessarily.

The point 6. of the OSI definition it about no restriction for the USE of the product (whether software or hardware). Says nothing about -production- of copies. Be it for selling or any other purpose. That is not by accident.

This license won’t stop illegal use any more than the GPL, but will make interactions within the community more difficult.

For example:

I’m allowed to take one of your designs and make an improvement. But then you are not allowed to use my improvement in your products, unless you make another modification.

Also, how much needs to be modified so it’s not a 1:1 copy anymore? If I (legally) modify 5% of the parts, then I can legally copy the rest? Who makes that determination?

Unfortunately, this is not a solution. You are not the first to ponder this problem, and you will not be the last.

I’ve seen no evidence that protecting individual commercial interests is possible in the open source world. Open source licenses actively prohibit individual commercial interests. The only way to make money from open source is to offer good quality and service.

Hi Joseph,

I respect very much your words on Open-Source. But the nature of the beast is terrifying, Be it the Chinese disrespect for our efforts in Open Source or some other countries. These people look at the money and they don’t care of licenses and respect of Open Source community. Their government will protect them and even sue you back and claim all background works as their own.

But I support any one that try to improve the Open Source licensing while protecting anyone that respect the spirit and wording of the licenses (H/W, S/W, Graphical etc.)

Good work Prusa

i think the closest workable solution would be to have patent databases (or something of similar authority) expanded to manage a registry of gnu lisenced developments and other major open source based developments which attributes open source code, files, designs, etc to their original makers. This list would also be checked against when a patent is filed so as to prevent patenting of open source based devices, code, etc.

It wont prevent closed source stuff being made from open source materials, but it would prevent such an entity from being able to patent it, and subsequently prevent abuse of patent law against the original makers.

resources to do this? i dont know where they will come from.

burden of filing registration? probably will keep minor changes which arent fundamnetally new off the main list. though it probably should allow you to attach your tweaks to an existing registered entry, though those tweaks dont get the same protection as the main entry.

summary: like a patent but doesnt prevent others from using it commercially. just prevent misattribution and abuse of patent law.

Once an avid supporter of Open Source (and having published many scientific software programs as Open Source) I’ve come to realize that essentially it’s… BS.

For most things published as OpenSource, if anyone wants to steal it, they’ll steal it, and most authors have no resources to respond to that in any meaningful way, As you said, the concept was developed by academics for academics where being copied is usually not a financial issue but rather a boost to one’s ego (I can say that, as both a former academic and former business person).

One of the comments to this post says:

> The lack of open source has been keeping me from buying a

> Bambu Carbon. I don’t like having to rely on a brand new

> company for parts. Open source means there will likely be

> parts for Prusas available even if it goes out of business

And that speaks to me to one of the basic misunderstandings of OpenSource. Availability of parts has nothing to do with OpenSource. I can have legally enforceable patents on my parts and still outlicense them (even for zero licensing cost) to others who want to make them.

To address the concerns some (and I would argue a tiny minority of users) might have about the ability to modify a system and to have access to parts does NOT require an OpenSource license. It is easily conceivable to have a portfolio of patents that allows you to protect yourself from cheap imitations (unless of course they’re in China but there’s really nothing you can do there anyway) and still freely outlicense components and welcome modifications.

Just to add (as I don’t see a way to edit my post):

Creative Commons licenses are just another example of stupidity. They’re just feel-good mental masturbation. E.g., I publish stuff on Printables with a CC-NC license. If someone in Thailand begins to sell it commercially, what am I going to do? Waste thousands of dollars on legal prosecution? In the US I may send a DMCA infringement notification to the hosting site, which may or may not do anything about it. If not, again, do I have the time or money to deal with it? Every day I see remixes that don’t acknowledge the source, in fact there have been contest submissions submitting someone else’s designs, CC licenses (or basic human decency) be damned.

If you want to stay in business you’ve gotta do what you’ve gotta do. Innovation is the main thing to keep you in the lead. Ensuring that copying innovation is not trivial comes next. And feel-good stuff like OpenSource licenses is not the answer.

Coming from the software world, this is a familiar cycle. Early entrants to a market will often lean on open source not only for the community goodwill and free promotion, but also to help “de-risk” a new product for early adopters. If it’s a new market, open source also helps create de facto standards, which benefits the first mover who will be viewed as the preeminent provider/implementer of the standards.

And then the markets grow. And many new players enter the market, and inevitably some new competitors, motivated by the now obvious commercial benefit of succeeding in the established market, liberally consume freely shared open source foundations. What was once a benefit for the early market leader is now also a competitive liability, unless, of course, buyers in the market still recognize and value open source as a “feature.”

You can find this cycle repeated countless times in software. Look no further than Android. Google shipped it all open until frustration with losing control over the experience pushed them to refactor more of Android in to closed libraries. Still, the decision to go open early helped Android flood the market with devices and firmly grab the #1 spot in mobile, so it served its purpose for Google.

As a Prusa fan — and I am — I want to see the company do what it needs to do to flourish and grow. To profit! So it can reinvest and make new things. As the saying goes, what got you here to begin with may not get you where you need to go. Don’t abandon your values and commitment to open source, but don’t be afraid to make changes that help you compete effectively in the next decade of 3D printing! Adapt or die.

Im largely in agreement with the new license idea, but im concerned about this line here: “The production of nearly exact 1:1 clones for commercial purposes is not allowed.”. The first thought in my mind was:

1. Who arbitrates similarity

2. How is the definition documented, so the definition of the thing doesnt change from one legal challenge to the next

3. This sounds like utility patents with extra steps and more ambiguity.

My first printer parts were a Prusa Mendel, and they were printed on a Cupcake. I adored the reprap spirit back then, and the infusion of younger folks who dont know or care about the community we used to be is, in my opinion, one of the biggest blows to the community, and industry at large.

We need a new license, but we also need to reboot the spirit of reprap in the community if we _really_ want to address the wrongs in the industry.

Just my short opinion: I think you guys are doing amazing work, and keepring things open source is a kickstarter for other people to innovate. This is super important for the technology of the future! but is is very sad that people are also doing the wrong things with your work and it is very good that you are working on a new licence to protect your work from people with bad intentions. Keep up the good work!

Thank you for laying out all your thoughts and reasoning on this topic, rather than just presenting it as a “This is our new license, deal with it.” kind of thing. I can see how frustrating it must be to see other companies creating copies of your work with out credit and renumeration, and potentially worse quality.

Going off on a tangent, I do love my MK3s and I’ve extensively modified it. I am now in the process of designing my own little printer (mostly to understand more about the trade-offs, but also to try out some different ways of doing things), and one thing I keep running into is the difficulty of sourcing the vitamins. Especially the hotend and bed.

This can be a big impediment for experimentation by individual users, but not so much for companies. For example there are some people trying to experiment with load cell based hotends similar to the new extruder on the Prusa XL and the MK4, but without a well stocked metal workshop it can be quite difficult to iterate over different version of the design.

I think getting more information on how the process of designing the new extruder went from Prusas experience would be greatly appreciated, but I’m curious how this information could be shared in a way to best benefit the community rather than just other competitor companies.

Dear Joe! You need to take care of your employees and your company.

I‘m sad to say that… We all learnt the last month that the community do not count on the value of open source. A lot of people are claiming that you only want to gain money and did not noticed what you (all Prusa members) give us back with open source. We also saw that the influencers do not support this idea because most of them simply need money.

My fear is that you will not survive the competition with open source approach. Take care!

Great post. papa’s pizzeria is a place for enjoy.

While I’m not a legal expert but following ideas comes in mind (non-lawsuit approach):

Community Vigilance:

Encourage the community to monitor and report any misuse of the project. This collective effort can help identify and pressure any dishonest commercial use and protect the original maker’s integrity.i think at least 40% of 3d printer user are also a member of open source community.

Together we are more powerful

Collaborate with said Commercial Company:

Engage with commercial users to create mutually beneficial partnerships, where they should either contribute to the project’s development, or provide financial support, or help improve the project in other ways. This can foster a healthy relationship between the open source community and commercial users.

Very good points, the new licences ideas are good and we need the same/similar more clear approach for all designs on Printables and Co.. As laws and this kind of stuff is always complicated and needs a long time I would like to have something controlled medieval kind of list with all companies that are not playing correctly. They should also be forbidden to use open source for at least one year if they broke the rules regularly.

Not so easy and just some quick thoughts.

Complaining about clones is rich when you already have too many orders is rich. You already have massive supply problems, fix those before adding more demand. If Prusa clones didn’t exist, you’d likely spend half a year shipping a printer instead of just months.

You are starting to sound a bit like IBM, complaning about x86 clones.

That article hurts my head:

1. Copyright infringement is a legal thing and needs to be prosecuted by courts, I don’t see what business Prusa has here

2. “China isn’t fair!” is something I’ve heard a million times. It’s ironic that this was used against DJI (because engineers from there went to found a certain new competitor) because they were ripping IP off for drones. I HAD a European made Parrot Drone before DJI came out, it was garbage. DJI owned the market because it made a better product. I had to constantly reprogram my drone in Linux to stop it crashing, which is how I got into 3D printing. The DJI drones just worked, for anyone, and my Mini 2 is one of the best investments I’ve ever made.

3. “We gave back more than we took from open source”, fantastic. That’s what I do with my models, all free and open, obviously on a much smaller scale. Do you want to start ratioing open source? Do to scale if you don’t put back more than you take it’s all 1:1 and we don’t get anywhere. Most of Prusa’s slicer updates come from the community, their slicer itself is a fork of Slic3r. That’s no excuse to suddenly go closed source or to start penalizing the community because some people aren’t ‘fair’. One of the reasons I bought Prusa and have recommended them for years was the open source sharing, it’s made them a lot of money.

4. “Corrective Actions” What are we, 12? Oh nooo… the years of good will are just melting away.

5. Where’s my day 1 Preorder of the XL I paid for blind within an hour of it being launched? I’m glad you had all this bandwidth for other projects but I’d like to get it before it’s completely irrelevant. When you announced it a large core XY at that price was amazing, but the competition is almost caught up and I still don’t have an ETA.

The situation in this regard is quite controversial. Because on the one hand, ethically I can only agree with what has been said and I am also a lover of the open source approach and of machines like Prusa, Voron, Ratrig, which allow you to mod, experiment and push the limits of printing more and more . On the other hand, however, we must note an obviousness that is increasingly evident. The consumer does not follow any ethics when buying, not even his own. Not just in 3D printing, but in general. Just think of the world of hardware, in which large companies have, in particular, undertaken completely anti-consumer marketing practices and which, despite this, have seen sale records one after another. Anyone who hangs out in the hardware world knows what I’m talking about. Logically, an excessive and clear continuation of anti-consumer practices should lead consumers to buy more responsibly and consciously, but, speeches and words aside, speaking only of facts, this is not the case. Pretending that the mass buys following an ethic is pure illusion, however sad and crude to admit, the facts leave no room for many doubts, the consumer does not follow any ethics or any ideology when buying. Coming back to 3D printing, the recent “bambu” phenomenon is just the latest example of a company unethically taking advantage of the open source approach. Furthermore, it is not even true that they have introduced high-speed printing, because in the Voron, Ratrig, VZ communities, it has been a reality that has existed for at least a couple of years, but we are talking about machines that need passion and a good grade of “technical expertise” in 3D printing.

That said i think that abandoning the open source approach would only be declaring defeat, with all the consequences of the case (huge loss of identity), a defeat that the 3d Printing enthusiast world doesn’t deserve, despite everything.

If you truly want to establish a new license for “Open Hardware”, I would suggest to look for help from organisations that have experience in this field, like the EFF maybe.

I appreciate the contribution PR has make to th3 community, BUT I think the are some issues that come to mind after reading this post. This past year especially, the mk3s+ was very uncompetitive in features and in price, especially compared to some newer printers on the market that came out at a similar price point with much better performance while not being 1:1 Prusa clones. The Mk4 is looking promising though, and I can understand wanting to protect it.

Anyway, if there was a significant decrease in Prusa printer sales this past year, I very much doubt that the proliferation of i3 clones was the main reason. People wanting a more premium machine than an i3 clone likely bought printers from competitors that were innovating, and those that did buy i3 clones didn’t see much value in buying a newer but mostly identical i3 as previous iterations, especially with significant lead times.

On the issue of clones, however, the situation is quite complex. First of all, complaining about the fact that many Chinese companies are able to supply products at lower prices is not only an ethical issue, but primarily a political one, especially a European one. Some of the clones, such as the clones of the famous E3D V6s, such as for example the mellows, or the Dragons, now evolved into Rapido (which start from the mosquito magnum project), really started from 1:1 clones, but which in just two years they have evolved considerably (bimetal heatbreak, TC4 heatbreak), offering better performance than the originals at a considerably lower price (and here again, it is more of a political issue than an ethical one). A consumer who goes to buy a product looks at the price/performance, and in this regard many products (now also of high quality) imported from China are simply excellent. Not admitting it would mean not being honest. Many companies have taken existing products and have considerably improved them, in this we should be more competitive, becoming aware of the fact that Chinese manufacturing companies are really very competitive.

As for the 1:1 clones of the printers, however, the matter is not just a question of price/performance, but also of availability. Many consumers have bought clones, in various periods in which it was necessary to wait several months (not a few) for an Original. This window was granted to them due to a slow production of the originals, so it also starts from a lack of the original company. Also in this, it is not only an ethical question, but it highlights some shortcomings and points in which we need to improve, competitiveness and production.

I am one of those people that exclusively uses open source software and particularly do not want to promote the use of closed software by surveillance capitalism companies with user hostile terms of service. I can not endorse open source communities building on closed privacy-hostile platforms like Discord and am excluded from most of the Prusa community as a result which is a shame. I hope Prusa will join Matrix or at least bridge their Discord channels to Matrix so open source advocates like me can participate in the discussion, but I digress. I give this for context to show that Prusas use of closed systems is already excluding at least some people.

Your post made some great points though. Hardware, unlike software, takes a lot of ongoing effort to manufacture and sell in a sustainable way up against endless Chinese clones. Copy pasting code to a new repo does not undermine your effort to fund hardware innovations but a saturated market of exact duplicate hardware does.

Open Source licenses all forbid restricting commercial use, but I feel this is a mistake when it comes to hardware as it stifles the funding of innovation that only comes from a larger well funded organization that might wish to still maximize a users rights over their own property.

As a near-stallman-level freedom-obsessed end user, I am satisfied so long as I can do whatever I want with my hardware, can load any firmware on it I wish, etc. So long as I can sell any legitimate improvements or iterations on that hardware or -resell- hardware I no longer need, we are all good. Restricting me from selling clones at scale as long as the original company is still actively selling theirs is totally okay with me as well. You make a totally fair case.

Creative Commons Non-Commercial comes here.

https://creativecommons.org/licenses/by-nc/3.0/

That is not quite right though because it might imply that I cannot use this product as a tool to make things for a company.

I feel it might be productive to work with the Creative Commons team to make something a bit like GPL amended only to forbid identical or near identical commercial hardware reproduction and sale would be a really useful option that might encourage other proprietary players to open up a bit as well.

Whatever you do, do it with external accountability with the Creative Commons, OSI, or similar neutral entity. A exclusively Prusa created and branded license would be conflict of interest and bad optics for others to use. Help make something even your competition can get on board with.

Best of luck!

Meh, once the clones for the MK4 come out, and they will, I will get one. You want to say you support open source using all those examples you gave on why you’re so “for” open source, and then complain about your hardware is being cloned. Dude, that’s open source. You either support it or you don’t. Maybe you should go the Voron route and not sell anything?

I understand that this is an incredibly unfortunate situation for Prusa, since you guys are basically enabling your own competition, seemingly without getting anything in return. What’s worse, much of the media has stopped covering the fact that these companies just take this IP without giving anything of value back to the community.

But for me, the reason I buy your products is precisely because I know that everything you do is open. A while ago, I wanted to change the look of my MK3, so I bought a blue anodized frame on Aliexpress. I’m pretty sure one of the main reasons I could buy this frame was because you made it very easy for people to make it.

You might say that you don’t benefit from somebody selling a copy of your frame, but I think you do, because I keep buying your products because I know that these parts will be available.

As someone also trying to build an open source business, I sympathize with your struggles.

However I agree with the sentiment in the comments that the idea for “The production of nearly exact 1:1 clones for commercial purposes is not allowed.” is completely the wrong move, and is not in the spirit of open source.

Yes finding creative ways to sustain a business like this is important, but I feel doing this would be crossing a line, at which point you may as well go all in on the closed-source business model.

One important use-case for me personally is that your shipping costs to my country are almost more than the machine itself. The only feasible way for people here (South Africa) to feasibly get a “Prusa printer” is through local manufacturers who make clones. None of them blatantly pretend it’s the original, but they don’t have to try and pretend that they’re not heavily inspired.

As an alternative, please consider embracing open-source and the community aspect more than you have before.

When I watch 3D printer reviews or discuss printer choices with friends, it mainly focuses on feature set and price. Rarely does anyone even consider manufacturing conditions (and location), repairability, maintainability, upgrade paths, community support, customer support, longevity, the ecosystem behind it, software support, open source, 3rd party accessories, and so on… But this is where Prusa is different from all the other brands, isn’t it?

Much of this comes from, or at least goes hand in hand with, open-source values. And if you’d embrace that, it could strengthen the growing community of people looking for more ethical hardware, build trust, and be an excellent example to other companies.

Maybe this isn’t the most brilliant business choice because of capitalism, but consider that success is not always the same as growth.

The state of open-source in 3D printing in 2023 is over, apparently. Because what’s described in here is most definitely the opposite of “open source.”

Here are my recommendations:

Your warranty and after sales support are the lifeblood of your company, sell more of that.

Create a Patent Pool for 3D printer Manufacturers. Enforce certain licensing requirements on members and create a branded trade name to indicate that manufactures who carry the label are part of a global open hardware alliance.

Franchise your brand to regional manufactures who pay a license for regional sales distribution. Focus on innovating in manufacturing practices, research and development.

Use your primacy in the market to force forks to upstream their changes or be left porting code. This means introducing breaking changes on a semi regular basis to encourage innovation, because otherwise forks will have to work around the breaking changes to access your own innovations in the software stack.

Embrace other companies who are working towards making open hardware a reality. Manufacturing, company organizational best practices, logistics, and design approaches are all rarely open sourced, but if you want partners in this space, you may need to grow them or build relationships with likeminded companies.

This is a tough spot to be in. The 3d printing industry today was built on open-source, from Prusa, as well as hundreds of other individuals and companies dedicated to the movement. As the industry grows and matures, companies seeking to profit off of the work of others have proliferated, and many of them add little to move the industry forward.

I 100% support Prusa, appreciate the massive contributions to the community over the past decade, and will always buy directly from Prusa to demonstrate my support.

A new license is only as good as the enforcement. If Prusa intends to spend a lot of money going after companies breaking the license, I support this idea. However, without enforcement, a new license doesn’t prevent bad actors from continuing to ignore it.

Having said that, Prusa would need a large, international legal department to do that. That would be a large drain on resources and a distraction to leadership that would likely impact and undermine the commitment to engineering advancements in 3D printing.

It might be worth considering building a separate non-profit entity that is a coalition of open source companies (and funded by both those companies, and individuals in the community), dedicated to preserving and protecting open source. Conceptually similar to the EFF, but focused on protecting open source. (Or perhaps even partner with the EFF?)

Open-Source Hardware Has been pivotal to my progress as an electrical engineer. It is how i would learn of novel solutions, find new inspiration and in overall improve my knowledge way beyond what engineering textbooks could teach me. Openly sharing knowledge is a core pillar of technology progress in general.

But to put it bluntly. Although intended to further knowledge like an academic source would. OSH is indeed being plagued by a incredibly powerful Trio: Companies who exploit OSH for an low-investment product they can make cheaply, Cases of hijacking and ofcourse consumers that mistake this “Race to the bottom” mentality exhibited as good competition and will happily endorse them cause getting stuff cheaper is all that matters to them. That isn’t what open-source hardware was meant to enable.

The only time when i see OSH work out well. Is when the result is either incredibly niche or of such complexity that trying to copy cheaply just isn’t possible without losing a lot in the progress. Otherwise it genuinely becomes more prudent to engage in a Copyleft license at the least and since that isn’t really available: Others like E3D are finding themselves having to betray their open roots and go proprietary just to be able to recoup their R&D investments. So i would concur that a better Copyleft license should exist. One that provides freedom of repair and to study, but does not just give you carte blanche to copy commercially. Creative works including 3D Models on printables can have Non-Commercial clauses allowing for study, remixing and learning, but not go and flood sites like etsy with mass productions of them, so…Why can’t our hardware creations have such things?

In the mean-time, the 3D-Printing market has become this incredibly vicious market of rapidly churned, non-innovative/proprietary printers all consuming eachother. Even BBL is starting to feel the heat as their cheap CoreXY has triggered a flood of competitors to start rapidly preparing their own CoreXY making it quite possible that BBL may already be yesterday’s news by the end of the year. To be just another notch on the race to the bottom.

I think you should also consider divorcing your trademarks from the open source versions of the products. Remove “Original Prusa” from the control interface plastic, from PCB silkscreens, etc. Then an honest cloner either needs to keep things sterile or come up with their own logos. A dishonest one is violating your trademarks.

I think Prusa should patent everything and then give free, conditional or very cheap licences to those who they want to give them to. Anything else is too complicated. Some things like 3D printed plastic component STL or ever STEP files could be released on Printables etc and some information could be be released so as to allow others to develop their own mods to work with Prusa printers. Customers will judge Prusa by how they then operate. I own 2 x mk3s+ with mosquito hot ends. I’ve got an XL on pre-order and want 5 X tool heads. I don’t care that Prusa’s cost more they are good quality and I’m happy to help pay for the next generation of printers Prusa is developing.

I do get the point but I think a new license will not help much because Chinese companies will not care what the license says until violations will lead to major business threats for them.

So instead I think it would be preferable to enforce the existing licenses. Most of the times I am not a fan of lobbyism but in this case I think that it would benefit both Prusa as well as Open Source in general if Open Source license violations would be prosecuted on EU level. One thing that comes to mind is blocking a company from importing their products to the EU if they violate licenses.

For handling hardware inventions in general I quite like the idea of patenting and putting the patent into an Open Source patent collective like https://openinventionnetwork.com/ for example. I think hardware patents will be easier to prosecute on EU level than licenses. But patents for software are a catastrophe IMHO and should not be legal at all. In that case licenses should be enough if violations are prosecuted.

I don’t know if it’s a good idea or not, but maybe Prusa can Patent their IP and still openly release their sources (blueprint/code).

That way, the legal side is more or less at it’s best and the sources are still shared with users and community but prusa can decide witch company can use it commercially.

Prusa can also drop the patent after a short amount of time say 2 years so it will return to full open-source after that period.

It is really far from a perfect solution but that way, prusa can choose who can use their IP commercially and decide if they enforce or not their patent on some company and/or maybe make some agreement.

It will not really block any innovations if prusa is fair with their patent enforcement (so other company that are contributing and are fairly using sources can still use it commercially) and if they drop the patent after a relatively short amount of year.

Other company can do the same thing and allow prusa to use their patent while also releasing their sources to the community.

Like I said it’s not perfect but I think it solve many concerns.