I’m sure many of you are already overwhelmed with all the news about the COVID-19 pandemic. However, after careful consideration, I decided to write this article and disclose what course of action we took in Prusa Research and how we managed to minimize the impact by staying ahead of the curve – this is mainly in hope that some of you might find our precautions and recommendations helpful. It’s no rocket science, just common sense, and responsibility.

Better safe than sorry

With so much news and changes every day, I find it almost unbelievable that it’s been more than four weeks since the coronavirus started spreading in Europe (mainly in Italy, which is a popular vacation spot for many Czechs). With all the things that needed taking care of, it feels like it’s been so much longer.

Once we learned about the epidemic, we immediately took action. Our team got a full briefing about potential dangers, which lead to our first list of measures:

- We have closed down PrusaLab, our makerspace/hackerspace, for all public and canceled Prusa factory tours

- All employees on a vacation abroad were advised to take two weeks off / work remotely

- Building maintenance/cleaning has been ramped up – more frequent cleaning, better cleaning products, high-quality disinfectant soaps available in restrooms

We did this (and more) days before the Czech government started acting. One of the more difficult things was to explain to our employees that they should already consider canceling their vacations, any travels, visits to grandparents, as well as not attending public events (e.g. concerts, sporting events). In the end, we offered our employees the option that we would cover their cancellation costs – it was better than risking an outbreak.

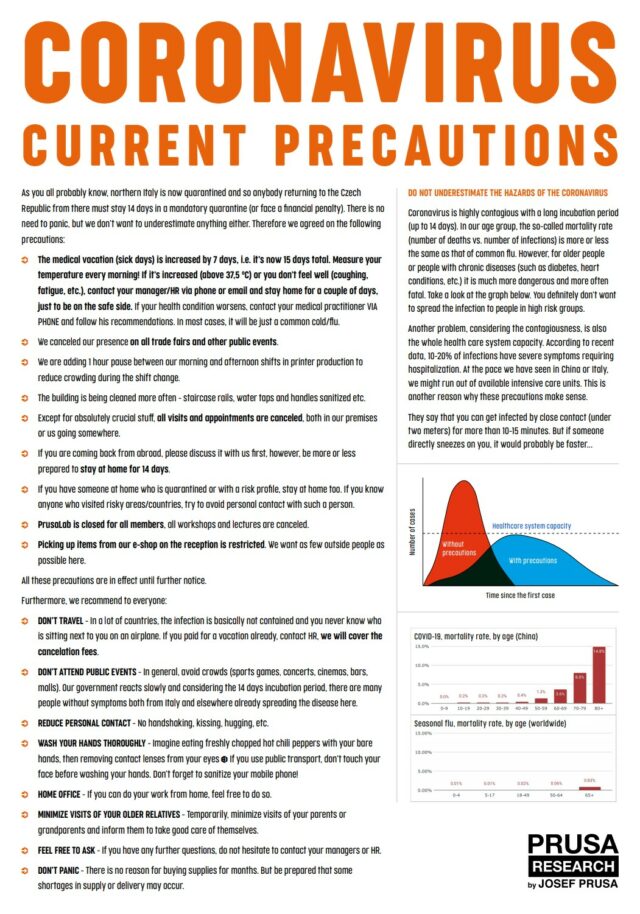

This poster appeared throughout the factory almost immediately. It was necessary to keep our employees fully informed:

Back then, many people saw COVID-19 as “just another flu” and while I was confident that there was no reason for panic, I went with the “better safe than sorry” option. After all, there are almost 500 people in our team, most of them sitting in a single location. I believe that mainly due to these preliminary measures, we were not affected by the disease.

A few days later, Italy was added to the list of high-risk countries and, by Czech law, anybody traveling from Italy had to be quarantined for at least 14 days with a threat of a massive penalty in case they would ignore it.

It was becoming more and more clear that the situation would become worse and things would stay that way for quite a long time. We decided to cancel our attendance at all the events we were scheduled to visit. Normally, there are 2-3 teams of 5-10 people traveling the world and attending various 3D printing shows, events and expos. Traveling started becoming riskier and that’s exactly what we wanted to avoid – unnecessary risks.

PSA: 1/3 I am sorry to announce this, but until further notice, we are canceling all the shows and events we were scheduled to go. We normally have 5-10 people teams traveling around the world 2 to 4 times a month and that is now simply impossible to do safely.

— Josef Prusa (@josefprusa) March 9, 2020

Common sense and responsibility

A majority of our team is of young age, so what was the fuss all about? Well, mainly about the fact that COVID-19 has a long incubation period and young, low-risk people could infect their relatives and people around them – e.g. senior citizens. Just a few days after our first COVID-19 briefing, we started adding more measures. Prusa Research is built around the open-source principle and open access to information, so being open about the situation was a natural way for us.

We knew that adding excessive limitations and enforcing impossibly strict rules could potentially lead to more problems (people could start ignoring them), so instead, we decided to assist our employees in these increasingly difficult times.

- Anyone working on a position allowing him to work remotely was asked to work from home.

- In the Czech Republic, everyone has health insurance by law (and free healthcare). Our employees have seven available sick days and we decided to add another seven sick days for the time being. To put this into context: Everyone has paid sick leave (60 % of normal income) until cured by law here in Czechia, as it should be everywhere. Sick days are our benefit on top of that, normally for things like a bad migraine. With sick days, you don’t have to think about such things as whether you should go to work if you have “just a cold” – you can simply stay at home because you don’t need medical diagnosis and you still get full income.

- Speaking of health issues – all our employees were advised that in case they don’t feel well, they should stay at home and CALL our HR department and their doctor

- Shiftwork was reorganized, so people from two shifts wouldn’t meet at all. And there’s an hour between shifts when the workplace is being cleaned and sanitized.

- We started adding automatic doors, so people don’t have to touch door handles – we already had an automatic security gate at the entrance, but you still had to open the main door – this is now also automatic. In general, we’re trying to eliminate any “shared surfaces”, e.g. by leaving as many doors open as possible (again to eliminate touching the door handles)

- Teams from non-manufacturing departments, who need to be present on-location (e.g. IT), were split into groups with shifts to minimize the number of people meeting in the building.

And again, we shared a list of recommendations: keep your traveling to a bare minimum, try to stay away from crowded public events, wash your hands thoroughly, use shared bikes or cars instead of public transport.

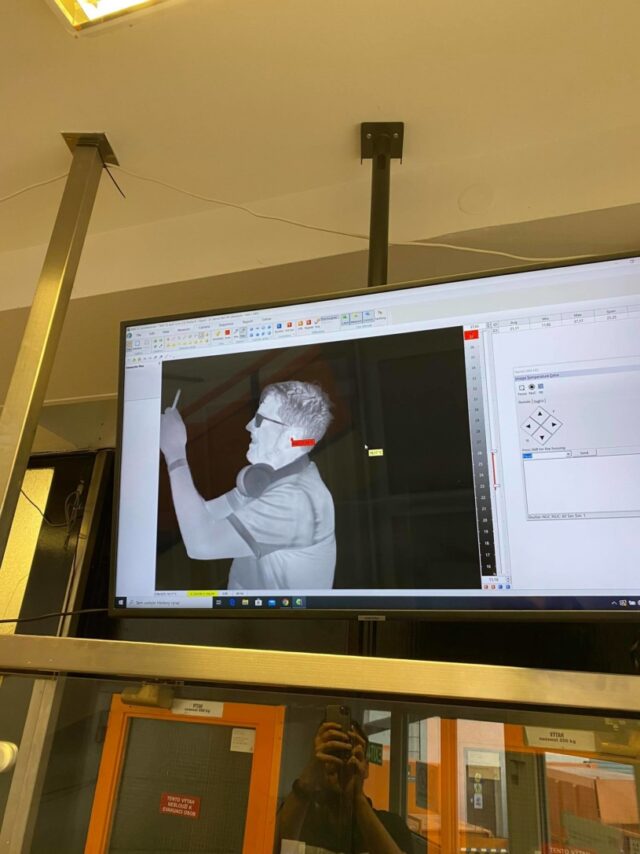

We also asked our employees to measure their temperature every morning, but we started working on a less annoying solution in the meantime – we’ve added a thermal camera next to the entrance gate, so every employee’s body temperature is measured the moment they come to work. To be on the safe side, we also bought a number of contactless thermometers and started doing random checks during each shift. And, as stated above, we’re trying to lower the number of places where people would need to touch any kind of shared surface.

Of course, in the ideal world, we would ask everyone to stay at home. However, this is not an ideal world and the company’s main focus is manufacturing – and it’s impossible to manufacture 3D printers at home. We still need those “golden Czech hands” (as the local saying goes) here in the factory. That’s why we went through all the trouble as quickly and effectively as we could. We acted much faster than the local government and even though some might have called our actions paranoid, eventually it turned out we did the right steps.

You might have noticed there wasn’t a single word about medical masks and respirators – something that’s completely normal in countries such as Japan. I don’t want to dive too deep into politics, so let me just say that there were no masks and respirators we could buy. After many days, we finally got our hands on enough masks just now, so starting today, everyone in the building is required to wear them at all times.

But we didn’t want to sit with our arms crossed, so we started inventing more plans – we wanted to keep our team as safe as possible.

Do it yourself!

A large part of the 3D-printing community revolves around the DIY principle – do it yourself! 3D printing is definitely not just about printing a statue or an action figure, it goes way beyond that. If there’s a problem, you don’t solve it by going to a shop and buying a solution, or waiting for someone to fix it for you. You go and figure it out yourself. So that’s exactly what we did.

The Czech government finally admitted that there’s a massive shortage of medical masks and respirators. Even to such a degree that doctors couldn’t get any. COVID-19 outbreak turned into a full-blown pandemic and people started to finally realize the impact of the situation and stormed the shops. Not only the food shelves were left empty, but also shelves with hygiene products, such as sanitizers. We already had a solution – both figuratively and literally.

The solution I’m talking about is an in-house-made disinfectant based on the guide prepared and approved by WHO. It consists of 99.8% IPA, 3% hydrogen peroxide, distilled water, and glycerol, stored for the recommended time of 72 hours before use in order to clear all possible germ cells. This was only possible thanks to our skilled Prusa Polymers team. These guys are usually working on new filaments or resins, but their skills were now perfect for producing a large volume of hand sanitizer and surface disinfectant, which will be handed out to our employees. We call it jokingly Mr. Prusa as a little nod to a certain other product – some lightheartedness in these times is required 🙂

However, with the shortage of medical masks, we needed to also decrease the risk of catching a virus in public transport. This is why we have funded the local shared bikes project (Rekola), so now they are free for everyone for two weeks in the whole country!

Also, we started organizing carpooling for our employees with financial benefits for the volunteering drivers. Carpooling is not too common here, most cars you see on the street are pretty much empty with just the driver behind the wheel.

Bikes are in these difficult times one of the safest ways to transport around cities. So I decided together with my friend @tomcuprcz to support bike-sharing @RekolaEU, now they will be free around the whole Czechia for the next and most difficult 14 days 🙏 Use yours! #COVID_19 pic.twitter.com/zDialns7gM

— Josef Prusa (@josefprusa) March 13, 2020

Stay safe, don’t wait

As I wrote in the beginning, the main purpose of this article is to inform you about the things you can do in a situation similar to ours and to share some important tips and tricks. Especially if the pandemic is only reaching your country and you still have time to prepare. The biggest lesson here? Do not wait until the government tells you to do something, that might be too late. However, I understand that decisions that affect the lives of millions of people cannot be rushed – there are things to consider, procedures to follow, laws to obey. This is all required. What I’m saying is: do not panic, be reasonably well prepared, follow recommended hygienic habits and get ready for the fact that your life may be slightly less comfortable for a few weeks or even months. We’ll get through this!

In just 3 days we started mass 3D printing of medical shields and we are donating 10k to our state. We are still tweaking and verifying the design on the fly with pros. That’s a must, false sense of security is dangerous. 3DP respirator info incl. #COVID19 https://t.co/9iQjoSuYl2

— Josef Prusa (@josefprusa) March 18, 2020

Thanks to the precautions we took, the cooperation of our team members (and some luck 🙂 ), nobody in the company is sick with the COVID-19. We didn’t have to put any heavy limits on our production or stop it completely, also due to our massive 2-3 month buffer on all important parts. However, we understand that there’s still the eventuality that the situation will get worse and we will act accordingly if needed. We’re constantly re-evaluating the situation because it changes every day. And in case of just the slightest suspicion, we’re asking our employees to stay at home (e.g. when their neighbor returned from a high-risk country, etc.). I believe the situation will improve once there are enough COVID-19 tests.

Unfortunately, what we need to do is to limit the availability of certain spare parts in our e-shop. However, if you need a replacement part, contact our tech support – we still have replacements in stock. Also, the lead time for small orders (without printers) could be longer than usual. And since you will probably ask anyway: the current situation (globally) makes it more difficult to source new parts for our upcoming printers. We’re doing what we can, but right now we’re focusing more on manufacturing.

Please, stay safe, be responsible, inform your friends and relatives about the real dangers of this situation, so we can soon start meeting again at all those awesome events, shows, and fairs!

I also recommend checking out two recent articles we just published – the first one is about how we went from a prototype of a face shield to full production in just three days.

The second one is about a new contest on PrusaPrinters – if you are at home and want to keep yourself busy, try to design a useful tool that can help others in these difficult times. Read the rules carefully before entering!

And remember, you can always find the latest news from Prusa Research on our social media channels.

Your employees must be glad to work in such a well organized and thoughtful company, also it’s awesome to see that you use your resources, time and energy to help in the corona crisis. Keep it up and stay healthy everyone!

Yes, what nils.kaluza said ! And thank you all for your work and useful products, generosity of information &c.

Also, thank you and apologies to Bart, our chat dropped as soon as I hit the login button. I then found ‘my account’ (which I was not able to find on the other page I was logged in to). Address added to, which should help DHL find us to deliver my new printer.

Best Regards, All

Scrivo dall’Italia, complimenti per tutto quello che state facendo bravi veramente, molte aziende italiane devono ancora pensare cosa fare, speriamo possano prendere esempio da aziende come la vostra.

qualche azienda italiana del settore stampa 3d sta producendo valvole per i respiratori automatici delle terapie intensive, purtroppo qui incamicia a scarseggiare tutto anche i medicinali cominciano a finire , mi raccomando state a casa il più possibile

ciao e continuate cosi GRAZIE GRAZIE GRAZIE

Can you guys provide any details on the thermal camera you setup?

That is pretty amazing! Good job to everybody in Prusa for being so organized. I work in the manufacturing industry and I see that people don’t necessarily take it so seriously…I hope employees there know how lucky they are. As you said better safe than sorry.

Dear Prusa staff – Your user community should be printing ventilator parts! I’m a Prusa i3 MK3s owner. I’d gladly volunteer to print. But as I understand it, the the strength of fused layer materials probably isn’t sufficient for current products. We need a biomedical engineer to design a ventilator that does work off such parts. They’d probably be bigger. I’m an electrical engineer, and I don’t think I’m the person to design that ventilator. But with your user list and email list, you are in a good position to make a call to your community asking for biomedical engineers to step forward and come up with a design. Then give out the *.stl files, and ask your community to print and ship. Just an idea. Sincerely, Tyge Legier, La Mesa, California.

PETG is referenced as the preferable material but I would like to use TPU. Do you know if there is any biological or sanitizing reason why TPU should NOT be used?

The customer service is HORRIBLE. My MK3S was working fine and has now been useless for over 2 months while going back and forth with support. Oh, they did send me a thermistor. WOW, that didn’t work. I really got upset when they said that a refund/replacement is no longer on the table because it is past the 3 month return policy. Well! It has not worked for two of the four months that I have had it and been going back and forth with Prusa about the problem. GRRRRR

Hello, I would like to write a review regarding such a wonderful website as PrimeTherapist. I never believed in psychologists, compared them to charlatans and pseudo-extrasensors. But sooner or later a white streak in people is replaced by a black one, this change happened to me. I decided to see a psychologist from this service and he helped me! After a few therapies, I began to feel much better, more vigorous. Life got new sensations. I recommend this site to all people because it doesn’t hurt to sort oneself out.

Useful research. I like your strategy for dealing with the Coronavirus. During this difficult time, many spheres have suffered from the pandemic, and the education system has received the hardest hit. In a study from the BBC, it was revealed that in 2020, the progress of students in distance learning decreased by three. I also noticed that I became less productive. I think that for the duration of the quarantine, I need to find a good writing service that can help me improve my grades. Fortunately, services like OnlineWritersRating provide reviews of the best writing services, and I definitely won’t be wrong about my choice.

It is really better to take care of yourself because it is better to stay at home for a while than to treat the consequences for years. I study at home for almost a year and for convenience I use essayreviewexpert.com and read reviews about various services. When I urgently need to write an essay or something like that I use Writersperhour. That’s why digital technologies predominate in all spheres now and it’s cool because we are developing.

Many online casinos use Bitcoin as a deposit option (as well as a payout option). It is safe and secure, the maximum amounts are usually larger and you can play with more anonymity.

This pandemic situation it’s really difficult for everyone. Even to be ahead of it. But it’s really great that the situation is quite good there. I also had wrote different essays about environment nowadays and made my conclusions about it.

Thank you for talking about this. In fact, I do not like how our citizens have become negligent about the precautions for the spread of coronavirus, without looking back at any of its strains. I understand how everyone is tired of living in fear and constantly wearing masks, but nevertheless, when our own life and/or the health of our loved ones depend on it, then it is worth thinking about it and enduring such precautions a little more. Not only your own life depends on this, and it is time to understand it.

Indica flower