PLA is the most used material in the world of FFF/FDM 3D printing. It’s safe, easy to use and affordable. After all, our in-house made Prusament PLA is a prime example. With its Galaxy Black, Prusa Orange and Galaxy Silver variations, it is by far the most popular material in our e-shop. Since we manufacture all our filaments directly in our HQ, we have complete control over their quality and a perfect overview of the entire process. It also means we need to deal with things like plastic waste which is generated during production. We felt it would be a shame to simply dispose of it, so we started researching how to use that waste effectively to produce something useful – like more material for 3D printing! And we’re excited that we can finally show you the result: the new Prusament PLA Recycled.

What is Prusament PLA Recycled?

We take no small pride in our filament manufacturing process. We even give you the option to inspect the manufacturing report of every single spool of Prusament you buy. Our materials have great color consistency, highly accurate diameter measured in two axes, perfect winding and more. This also means there’s a very strict QA control in place. Not every spool meets our strict requirements, so there’s a relatively substantial amount of waste, especially when we find an error on a nearly finished spool. Of course, we use up many of these “unsatisfactory” spools internally, so they don’t go to waste. However, there are some beyond saving. And precisely these spools are used for the production of the Prusament PLA Recycled, which contains 100 % of recycled Prusament PLA materials.

There are no further additives or pigments mixed with the recycled material. Every time a new batch is produced, the filament has a completely unique color. In other words: the color of Prusament PLA Recycled is determined by the colors of filaments thrown into the mix. Currently, we offer recycled PLA on a large 2kg spool, which also means you need to upgrade your spoolholder with a new 125mm variant. You can download the updated design here (Original Prusa i3 MK3s+) and here (Original Prusa MINI+).

Print quality

Compared to our standard Prusament PLA, the Recycled version has a slightly higher manufacturing tolerance (±0,05 mm) and it doesn’t have the perfect winding – but the filament strand is still quite nicely aligned to ensure it won’t tangle up. We’ve been testing the new material for months and went through dozens and dozens of spools without a single hitch before we concluded that Prusament PLA Recycled can deliver compelling printing performance and it’s a great and useful addition to our Prusament lineup.

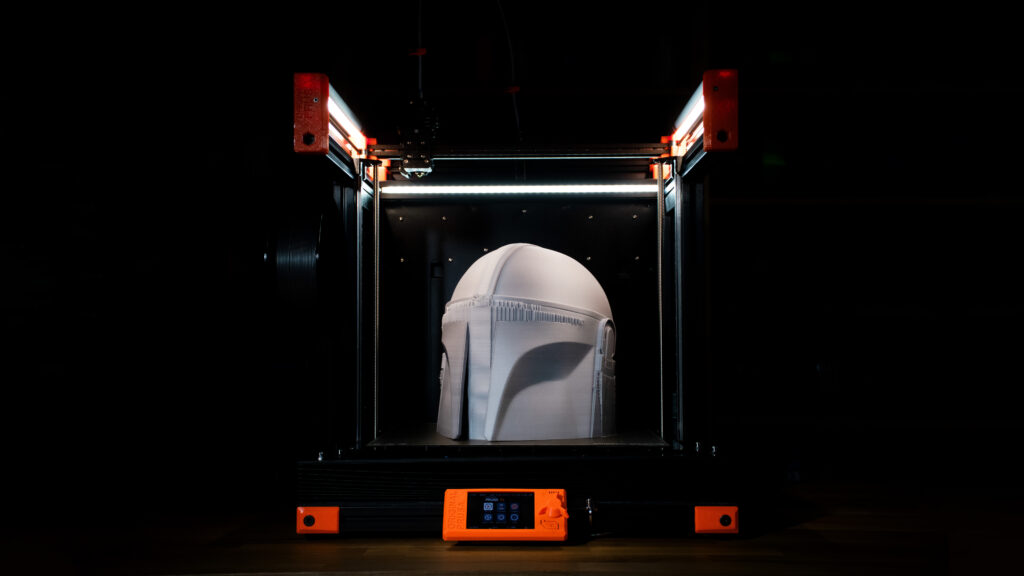

The standard Prusament PLA still delivers better results thanks to its more strict manufacturing tolerances, but if you’re looking to print, e.g., large objects which will be later post-processed and painted, the 2kg spool of Prusament PLA Recycled is a great choice. You can easily cover its color with a filler spray and the 2 kilograms worth of material will ensure you won’t need to switch spools during long prints. Or maybe you’ll actually find out that the newly produced batch has exactly the color you’ve been looking for. 🙂

Also, there are no changes in PrusaSlicer configuration. You don’t need to import any new profiles – simply use the proven Prusament PLA profiles. The Recycled version works with existing profiles perfectly.

New uses for recycled materials

You have probably noticed that we also minimize waste by using a smart design in our spools. The core of the spool, made from cardboard, is combined with lightweight plastic sides. We even researched spools made entirely of cardboard, but in the end it wasn’t a suitable solution for us. This is why we use cardboard only for the core of the spool where it functions well. The cardboard we use is FSC certified, it is made from recycled materials and can be further recycled. It makes up to 20 percent of the total weight of the 1kg spool variant and up to 29 percent of the 2kg spool.

Iterative development, prototyping, improved designs… Those are all the main characteristics of the 3D printing industry. And our spool designs follow in the same direction. This Summer, we started manufacturing the plastic spool sides from a 100% recycled polycarbonate (PC). So if you have a fresh spool of Prusament on your desk, it’s probably already made with recycled materials.

We would like to make further improvements. Polycarbonate waste is a rather common commodity which we buy from various sources to produce the sides of our spools, however, our next goal is to use waste created during the manufacturing of Prusament PETG. We want to use recycled PETG in combination with injection molding for the production of spool sides, so we have more options than just recycled polycarbonate.

Pricing and availability

Back to our new filament! I bet you’re curious about the pricing and availability. One 2kg spool of Prusament PLA Recycled is 44,99 USD / 46,99 EUR (incl. VAT), which means it’s a bit cheaper than standard PLA. As for the availability – the production volume depends on the amount of waste produced. This is why the number of available spools in our e-shop will be limited. The first batch of Prusament PLA Recycled launched right now consists of 500 spools.

Be sure to let us know how you like printing with the new material – we’re looking forward to your feedback!

Happy printing!

Very cool. Any thoughts about also collecting user filament waste?

That would be a great idea too, the problem with that is that you have no control over the kind of filament you can receive from users 🙁

But I can imagine a kit for recycling your filament at home! That would be great too!

There are d.i.y. kits for filament recycling. You can also buy complete machines for at home or small company. But is is not cheap and it is time consuming.

Oh yeah, I saw something like that, but thank you! It also depends on the quantity of your filament waste. It’s pretty difficult that a “normal” person will use this much filament.

BTW My idea of a kit was directed to Prusa, but obviously, it brings a bunch of other issues and complexity for the already complex world of recycling.

Wonderful news! I’ll try it for sure! No need to use my nice Prusament for early prototypes when you have Prusament Recycled!

BTW Once I have a bunch of plastic sides from my empty Prusament spools is there a way to send them back to you for recycling? Wouldn’t it be great to have this kind of service?

We could send you back spool sides and have some kind of points to accumulate and maybe have a discount code after a certain number of points.

Obviously, there are positive and negative sides to this idea but thinking is free.

Cheers,

Vlad

Hello,

I’m glad you are eager to try our filament. 🙂

About getting the spools back: we have actually thought about doing that but it’s obviously quite difficult to make it work. We will surely let you all know if and when we launch such a service.

Maybe it will ne much easier to become a bit more environmental friendly by just offering refill spools for the master spool standard?

There are already models to convert prusament spool to master spool 🙂

I don’t understand why the sides of the spool can’t be made from strong cardboard as well.

I happen to have the same problem soon 😀

Many spools are getting empty and I would really like to send the sides back because throwing them away would be a little wasteful :/

All the best

Also as a main comment… the logical next step is to make the sides of the spool out of cardboard as well. There is no need to use plastic there.

I think they tried that but the cardboard is too weak for the sides, especially if you vacuum bag them

If you use the cardboard used in a standard shipment box; yes. But the packaging industry has much more to offer. Also cardboard that is strong enough. My feeling is Prusa should look into it.

I find it funny that the printer community is so obsessed with recycling and waste reduction when the vast majority of prints is stupid trinkets.

If someone is really concerned about plastic wastage then it’s much better not to print those models with no practical purpose and limited aesthetic value.

This way much more plastic can be saved than by putting huge efforts into eliminating parts of the spool with real practical purpose.

I absolutely agree with this and think it is a bit embarrassing for such a big name like Prusa to not do it while other big brands sell most of the spools in cardboard. As I have used up lots of cardboard spools up til now, I can tell that it works. I am also vacuuming the spools for storage. Yes, the cardboard sides do get bent, but who cares about that? It never lead to any problems. The sides are flexible, if the are getting bent to much, they can easily be “straightened” again. Meanwhile I broke more than one plastic spool by vacuuming.

I wish there was a way of recycling empty spools or having degradable ones. If a manufacturer offered a refill option, even if it involved returning empty spools and paying for the postage then I would buy exclusively from them.

I just started on 3D printing. And I can tell I am lucky enough to one o e. It is the mini, I am loving. The Prusament black galaxy is awesome, I tried another brands and it clear stand out from the rest.

Would love to be able to send my Prusament PLA waste back to you to recycle.

I’ve been keeping hold of it to recycle but really struggling to find anywhere in the UK that takes it!

Its really putting me off printing too much as I like to minimise waste. If I knew I had somewhere that would recycle the PLA I use I would definitely be printing more.

Is there any way to get this in a masterspool?

It would be cool if we would be able to send back the plastic parts of empty filament spools because they stack up over time and it feels bad to throw them into the bin.

I can’t wait to see if you have progress with recycled PETG! I use primarily PETG myself and I wouldn’t mind at all using recycled filament whenever possible.

(I’ll also echo others and say I would also love to be able to send in waste for recycling somewhere, though I respect the difficulties in ensuring the filament received is actually what it’s claimed to be)

I’m curious – what was it about fully-cardboard spools that wasn’t viable for Prusa? I’m assuming dust accumulation problems in and around your winding equipment, but it would be interesting to hear more on that.

Oh! I should also say I found out recently that PolyTerra apparently ships their filament on wooden spools. That might be worth looking into as well, though your use of recycled cardboard core and polycarbonate sides are good as they are 😀

Hi guys!

The idea is great, let’s save our planet.

Between the shop pictures, you have a seed starter. Where can I find that model?

Thank you!

If you’re going to use plastic in your spools, then PLEASE put a recycle symbol on the spool flanges. That’s one thing that bothers me about every spool I have ever bought. I cannot throw the empty spool into the recycle bin because there is no recycle symbol on it. It’s nice that you’re using a cardboard core, but if you aren’t labeling the plastic of the flanges, you’re still contributing to waste. I don’t know why spool manufacturers never bother. It isn’t hard to do.

I would say that 100% plastic spool with a recycle symbol is better for the environment than a mixed-material plastic+cardboard spool even if the plastic was labeled. Recyclers don’t like separating different attached materials.

So you can’t take the spool apart by yourself to separate the core from the sides? On the other hand, I would absolutely agree with you that the plastic sides need a symbol to make clear what material they’re made of. No brainer.