The structure of a material defines its properties. The Faculty of Transportation Sciences at Czech Technical University conducts advanced research in this area and holds high ambitions: To significantly improve production processes in automotive, aviation, or space exploration. Imagine you need to build a car body or a space suit that need to withstand an impact of a certain force and deform in a certain way. Thanks to this research, you’ll soon be able to achieve that just by setting parameters, and the AI will generate recommended materials and structures with properties exactly matching your needs. However, this kind of research requires data, loads of data – that you need to gather through practical experiments. And this is where 3D printing steps in!

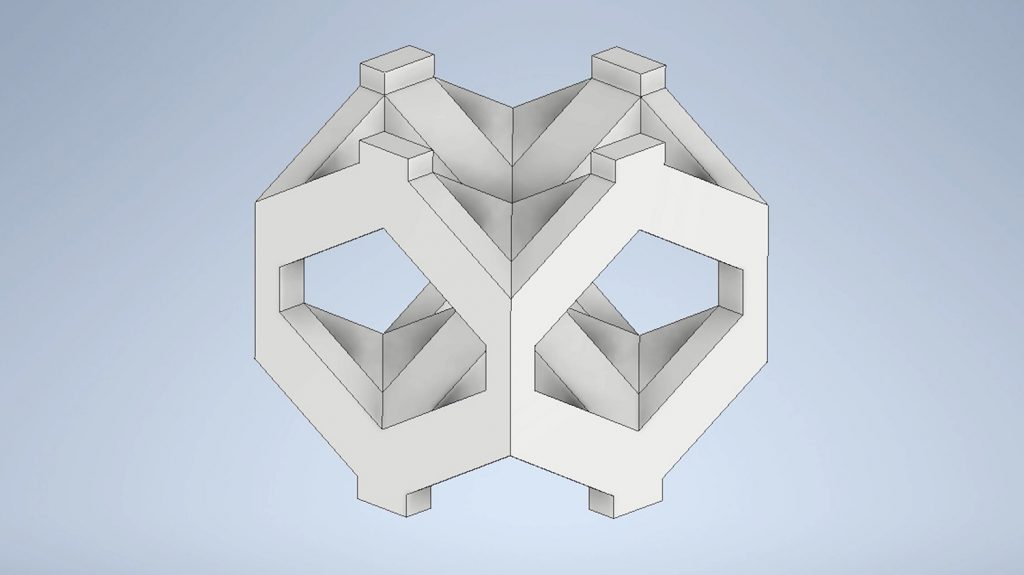

Professor Ondřej Jiroušek is in charge of this research and he showed us how it’s done: during the experiments they use 3D-printed objects of different structures generated by an AI. They look almost like decorative models from Printables 3D design contests, but in fact, they are a bit more sophisticated.

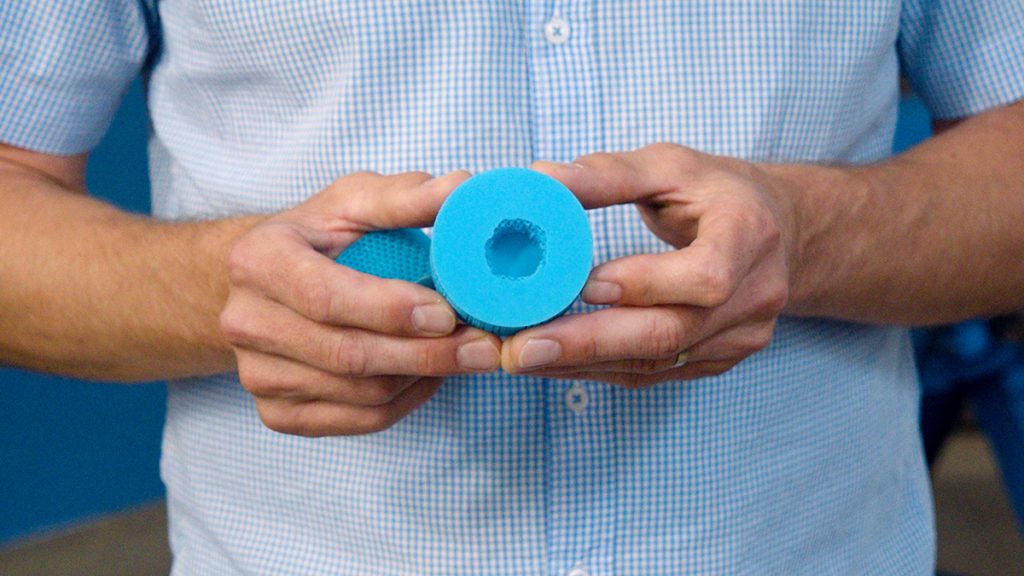

“Each sample has different properties and each structure behaves differently,” explains prof. Jiroušek. He shows us a 3D-printed sample that looks like a hockey puck – but with a visible peculiar infill pattern. “It looks almost like a honeycomb but it’s designed to distribute pressure force in a certain way.”

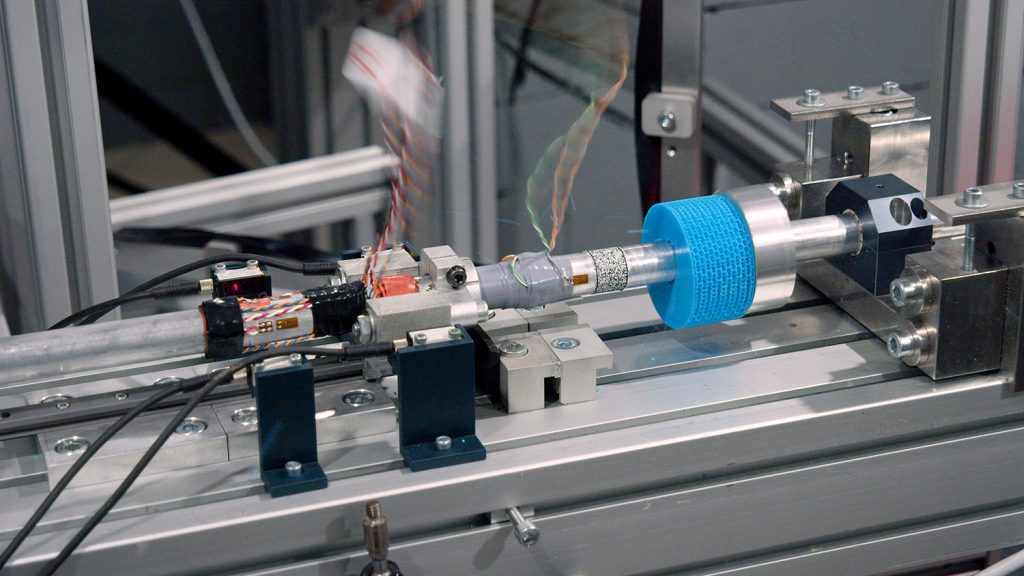

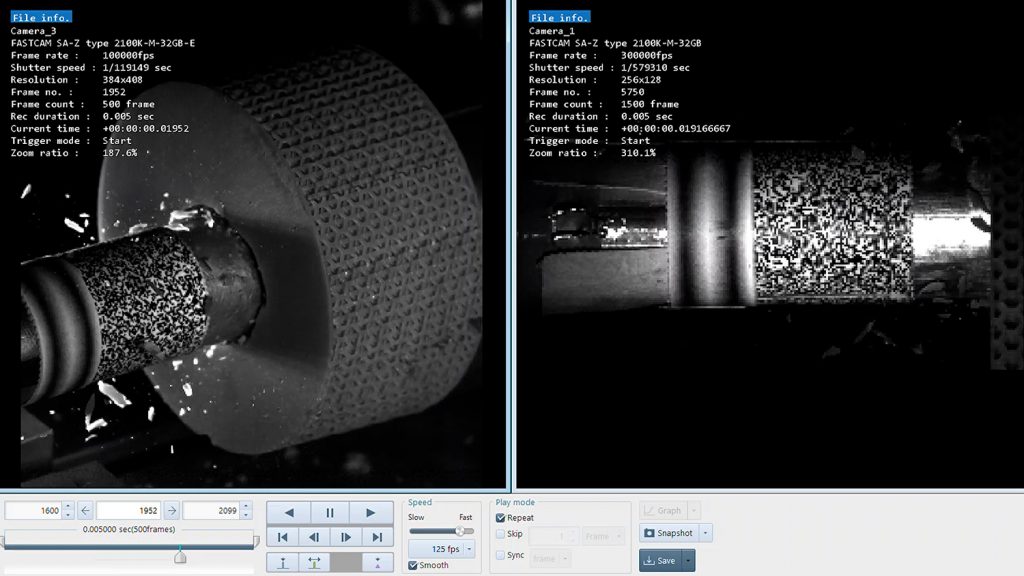

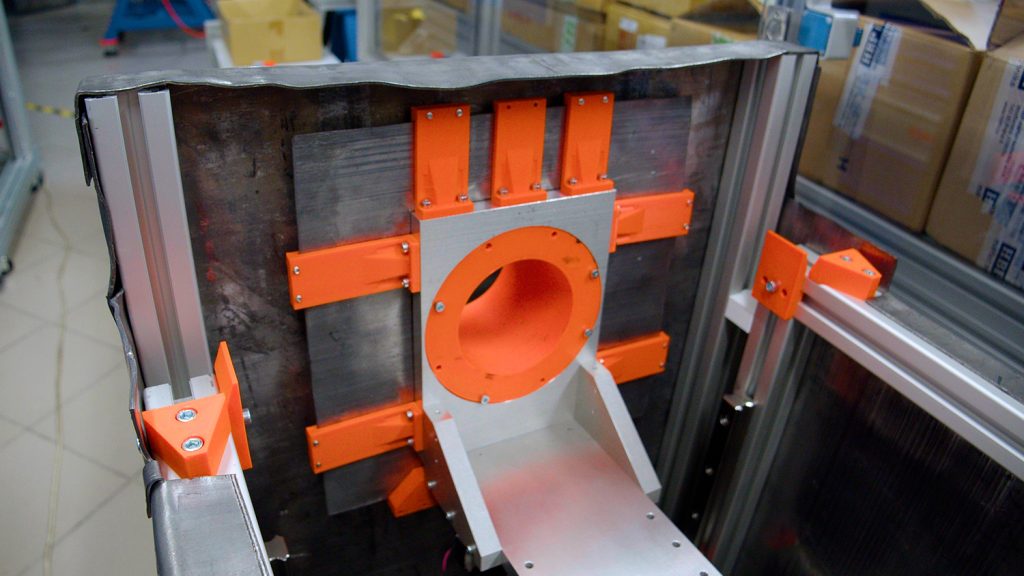

Experiments take place in a special laboratory for dynamic testing of materials and structures, called Dynlab. It’s full of all kinds of scientific equipment, but the most eye-catching one is surely the Split-Hopkinson pressure bar, used literally for shooting at the 3D printed objects. You place the object between two bars and then you launch a projectile from an air cannon. The striking mechanism hits the first bar which then hits the object and deforms it. It’s not only a fun experiment but also the slow-mo shots of the impact are very cool.

We saw different results on different samples – from a relatively shallow hole to a cracked and deformed object.

“The goal of these experiments is to map and understand the behavior of different structures under certain scenarios. The results of the experiment can be translated to numbers and we can make mathematical models. The research should lead to developing new kinds of protective wear or structures that protect against impact,” says prof. Jiroušek. A new research project in cooperation with North Carolina State University is also being prepared, exploring the possibilites of using artificial intelligence during the design process.

The FDM and SLA 3D printing technologies significantly help researchers with their tasks. You can find Original Prusa 3D printers in their labs – namely, MK3S+ and MINI+. Both teachers and students also use their 3D printers for making practical accessories for their research or to repair or improve their equipment.

And students can’t get enough of 3D printing.

“3D printing is very beneficial for the students and it’s also very easy to get into and fun to use. And that’s the best combination,” says prof. Jiroušek with a smile.

Website: cvut.cz

Now researchers around the world are using the technology to manufacture structural steel and metal components. Also known as additive manufacturing, 3D printing creates solid objects by successively piling material layers, one on top of the next, from a printer head. Slope Unblocked

Bigg Boss Season 18 is readily available for streaming on a variety of platforms, ensuring that you never miss a moment of the action.

https://biggbosslive.pk/

This video is meaningful to me. It helps me so much in my job. io games

Your writings stick out to me since the content is interesting and simple to understand. Even though I’ve read a lot of websites, I still like yours more. Your essay was interesting to read. I can understand the essay better now that I’ve read it carefully. In the future, I’d like to read more of your writing. mapquest driving directions free

An insightful exploration of the intersection between 3D printing and scientific research on materials and structures. It’s fascinating to see how technology like ChatGPT Online can play a role in advancing these fields, facilitating collaboration and knowledge exchange.

This impactful video significantly aids my work, providing invaluable insights and support. Grateful for its meaningful contribution to my job. <a href="https://storysaver.page/">story saver</a>

This impactful video is a valuable resource for my work, providing significant assistance and enhancing my job-related skills. Grateful for it! https://storysaver.page/

Enter a world where languages clash, cultures collide and creativity thrives. Introducing <a href="https://gptdeutsch.com/">ChatGPT Deutsch</a> – your ultimate gateway into the impressive realm of artificial intelligence! Prepare to unlock the power of language in unprecedented ways.

DramaCool is the best platform offering you a Asian Dramas tv shows free online.

Dramacool is free for every one high-quality videos will not let you down website.

https://dramacool.com.tw/

KissAsian is the best website to watch Asian Drama 2024 online free in high quality.

where you can watch Movies and kshows without any sign up or registration fast servers.

We provide Dramas Hd Premium quality with English Subbed for Kissasian drama lovers.

https://kissasian.cab/

Saveinsta is an Instagram post downloader website that helps you to download from Instagram online without any application or software. You only need to open a browser and paste the Instagram post link.

https://saveinsta.one/

DramaCool is a Best and famous online platform that offers a wide selection of Asian

dramas and movies for streaming. You can get daily episode of asian dramas free in hd.

<a href="https://dramacool.com.im/">Dramacool</a>