So 3D printing has pretty much been the same for the last couple of years. The technology is here and as I already said for many times, everyone (I can vouch only for me though) should be trying to make it as user friendly as possible. Sometimes it is difficult to explain this philosophy to 3D printing newcomers. We are making things which already exist better. I don’t much like the idea of adding gimmicky features just to stand out in a spreadsheet like comparisons.

I am stoked as it seems like it’s starting to work out. I would never expect reviews like we got in the last few weeks in my wildest dreams! We are Tom Approved now after all! We formed an exceptional community spanning from our forums, through facebook to Reddit, thousands of MK2 users spread their experience!

Thank you!

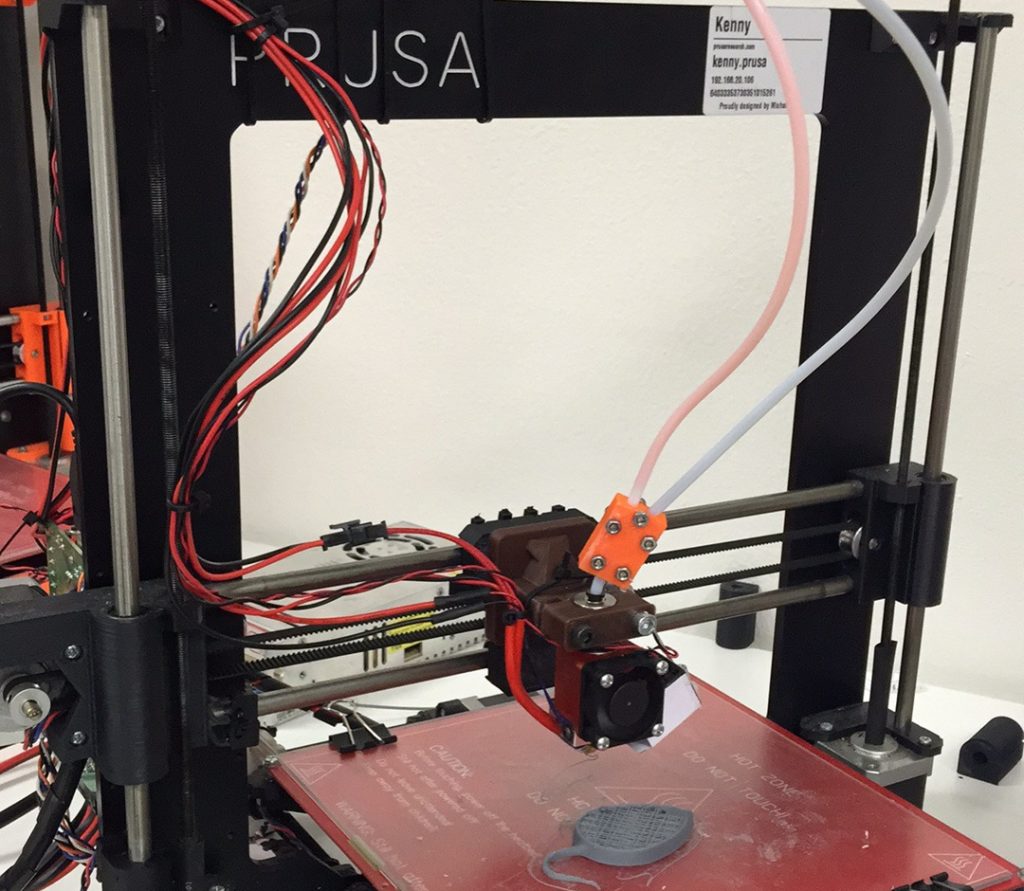

Now it is finally time to do something new. Something I had in my drawer long before I switched to 1.75mm and the Original i3 kit was widely known 🙂 In 2015 we were just competing in a 3D printer shootout here in Prague with the old trusty 3mm i3 and we didn’t finish up spectacularly good. Hurt ego can sometimes be a great source of motivation. So I got into playing with new parts and the more importantly 1.75 mm filament. This ultimately led to the “MK1” but in the meantime, after realising how much more versatile the 1.75mm filaments are, I couldn’t resist trying out Y shaped bowden splitter enabling two materials in one hotend. So on May 25th 2015, our loyal test printer named Kenny received this magnificent upgrade.

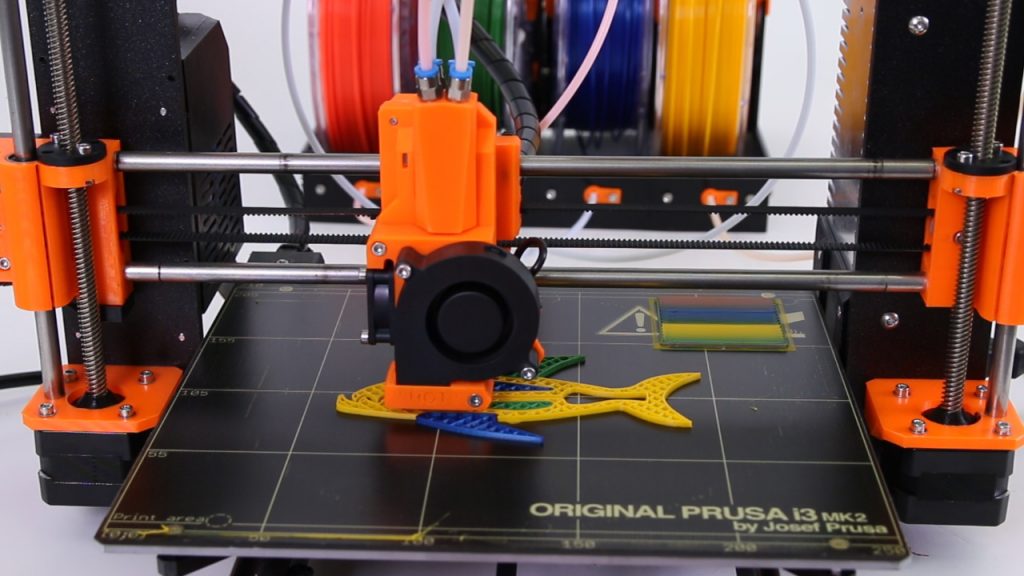

Exciting times! I got it working reliably enough to print couple objects including a dual color dice!

Back then there were many things I couldn’t solve by myself, like how to store the excess filament during the cleaning of the nozzle. Take a look how it was printing!

Project got shelved and I worked on the “MK1” with my brother Michal until it was released on August 26th 2015 (http://prusaprinters.org/prusa-i3-is-now-1-75-mm/). Fast forward to 2016, the team got more devs and with MK2 being so successful we are ready for increasingly more daunting tasks.

In meantime few others showed up with the similar idea but it never got enough traction. Prusa Research is known for perfect documentation, firmware/software integration and together with our awesome support we can make this happen. EDIT: There is one honourable mention, and that is Davide Dalfiume who apparently predated us by far. EDIT2: And MarlinKimbra with the multiplexing board. EDIT3: And Adrian Bowyer predated all of those previous mentions. Check it out.

Original Prusa i3 MK2 Multi Material upgrade

Let’s take a look at how it was done previously on other printers with dual extruders. Adding just second material (that was often the maximal limit of electronics) ment adding second complete extruder assembly including hotend. This introduces plenty of problems. Increasing the weight on the extruder carriage. Twice as much wiring. Twice as many things that can break. Reduced build volume by at-least the distance between the nozzle tips. And the most painful at the end, the incredibly hard calibration.

When we move to the printing itself, there is always a problem with the second hotend as it will slowly ooze material and embed it in the printed model, ooze shields were created to fight this problem, but they don’t work on bigger models.

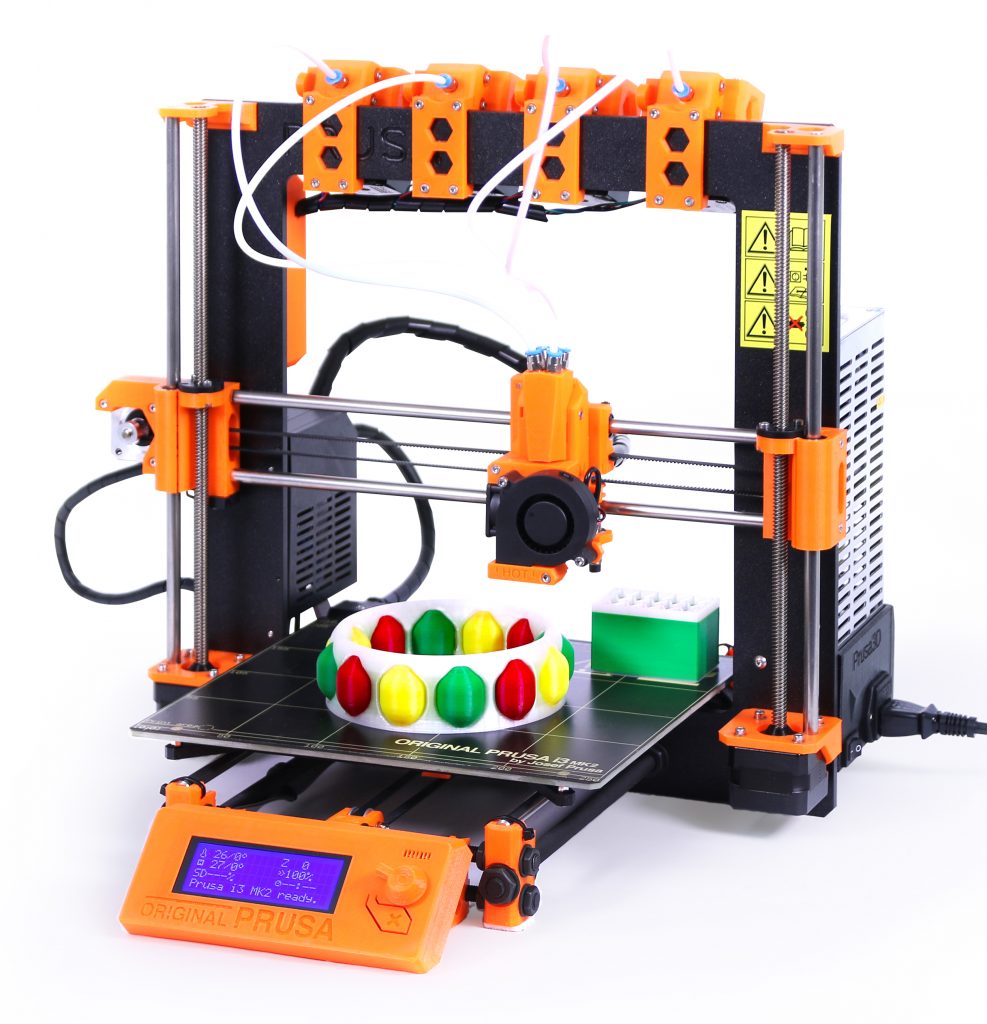

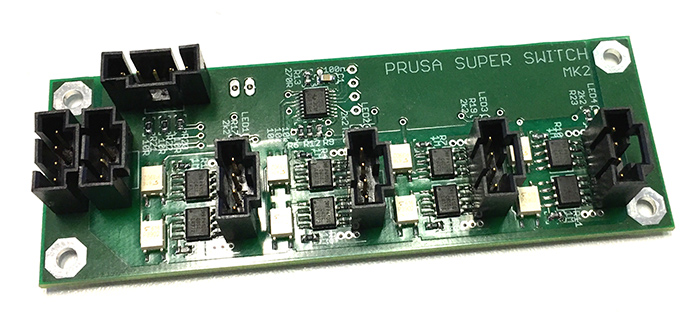

Upgrading the number of materials to 4 added a lot of unexpected complexity. First challenge was how to connect all the motors. As always we want to provide upgrades to all our users. But the RAMBo mini which we use only supports one extruder stepper by default (by design there is no need for more heaters and thermistors in the multimaterial upgrade). Replacing the motherboard would be costly, not to mention there is none with support for 4 extruders around anyways. I got an idea and after a few tests it turned out it is entirely possible to multiplex the motors. Sometimes simplest solutions are the best. So we created specialized board which does exactly this. It can be even expanded to multiplex more motors, but let’s leave that for the future.

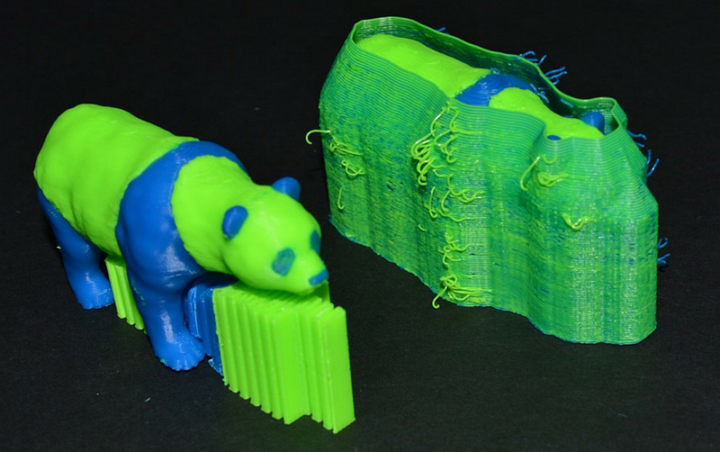

The second problem we had to overcome is where to store the excess material during the filament changes. At the beginning of the change, filament is quickly rammed so all the molten mass is extruded and then quickly retracted out of the heater block. This ensures minimal residual material before inserting next filament into the hotend. Smart wipe tower still needs to be generated to prime the hotend and clear the residual pigment though.

It needs to be smarter than any slicing software achieved before. If you have only two materials, there is only one material change per layer and you can get away with simple “layer change” script. With 4 materials, the whole gcode is analysed before to find out maximal number of filament swaps during one layer. This determines the number of “slots” in the tower and ultimately it’s size. If the number of required slots reduce during the print, tower will shrink and will not be generated after the last change is done. It is pretty smart™

The whole process is stupidly simple in theory, but devil is in the details and execution. But I am 100% positive, this is the future of multi material FDM printing.

There is a number of key advantages:

- Perfect alignment of the colors. It pretty much can’t be better 🙂 Zero additional calibration on top of the regular MK2 calibration.

- NO OOZE SHIELDS! They are soo 2015!

- The build volume doesn’t shrink with each additional extruder. Only small (3x5cm tops) smart tower is generated and can be positioned freely on the build plate.

- No special motherboard is needed apart from our multiplexing board. This also allows for easy upgrades of standard solutions.

- Regular E3D hotend can be used or reused during the upgrade.

- Very light load on the extruder carriage.

There are few disadvantages:

- Bowdens aren’t super friendly to the flexible materials but we already have ideas of mixing direct and bowden style drives.

- Materials with vastly different print temperatures cannot be printed at the same time. But this is theoretical as printing ABS and PLA at the same time isn’t a good idea anyways because of vastly different heatbed temperatures. Small temperature changes can be done during printing the smart tower.

When, how and how much

Well first thing I need to tell you now, creating 4 material models is hard and there are almost none on sites like thingiverse. Making truly multi material objects isn’t as easy as applying a texture. Each material needs to be a different object and all need to interconnect in 3D space. In this sense, the 4 material version is only for advanced users. However, a lot of our users love ColorPrint and this upgrade enables fully automatic color changing for 4 colors, this alone is an incredibly helpful feature.

2 material version is for users who mainly plan to print with soluble supports and don’t care much about colors 🙂

We decided to go with beta test first, after all this is vastly different than anything available and I believe it is the first 4 material solution ever which goes beyond prototype.

To apply for beta test, send us an email at [email protected] with “Multimaterial BETA” subject. Please include your MK2 projects and ideally 4 material model you created. We are looking for advanced users and we plan to pick around 30 beta testers.

All beta testers are chosen.

With final release we expect shipping by the end of November 2016 and is it available for preorder.

4 material version is $249 or €269 with VAT

2 material version is $199 or €219 with VAT

Update 1/8/2018: It is a long time ago this when I wrote this article, and there were a lot of changes after that, so some information became obsolete. I’ve updated the article (original info is crossed out) and add new prices and links. You can also check the first and the second update article about Multi Material development. There is also an article about printing soluble interface supports with Multi Material.

4 material version is $299 or €329 with VAT

Order now on SHOP.PRUSA3D.COM.

Hi Josef.

Pretty cool. Which slicer have you adapted to automate the material changes as you described?

Best wishes

Adrian

Hi, we have custom post processing script 🙂

Could I have that? That would be nice…

Really amazing !!!

Looks awesome, roll on November! Is the 4 spool dispenser in the video available too?

Hi,

Will you be selling pre-assembled printers with this upgrade kit already installed?

Thanks

Ross

I am a bit troubled by the fact that there is a problem with higher temperature differences between the switching of filaments. Isn’t it possible to adjust the temperature of the nozzle when the print head switches to the waste pile?

Best regards

Printhead

Can I use the printer with a http://reprap.org/wiki/Diamond_Hotend ?

I saw online the that you are taking applications for beta testing for the quad extruder and I would like to do so.

I have the Prusa i3 mk2 and would love to beta this and possibility post videos to my channel is that’s acceptable.

Please let me know if you need anymore info!!

Another vote for the ‘this just clinched an Original Prusa i3 MK2 purchase’, I’ve been waiting and waiting like a kid waiting for a sweet shop to open and how glad I am for that sweet shop to be “Josef’s”……..keep up the fantastic work! Rob

quiero comprar una nececito precio y envioa ,argentina CAPITAL,GRACIAS

will the 2 material version be able to print flexible type filament and pet/pett or nylon.

it would be used for disability adds and wearables with a strong plastic core and and flex outer

> Bowdens aren’t super friendly to the flexible materials but we already have ideas of mixing direct and bowden style drives.

This is the most exciting part for me.

Some flexible filaments use the same temperature settings as PLA, and this would mean, you can seamlessly print movable buttons in 3d-prints or add rubbery texture to objects.

Or a thousand more things. (hinged parts with rubber connection. seals for water proofing. A dragon example print with flappy wings 🙂 etc. )

Please make this happen, pretty please?

On preorder no color can be selected. Is black available besides orange, matching the printer color?

I see that it can print all 4 colors, but can it blend the 4 colors?

Hello,

I am curious as to how the advancements with the flex filament are going, are you able to print with the harder flex filaments under very low speed and low retraction? Or is it that all flex filaments are difficult to print with?

hi can you give me the price in uk for this 4 colour printer does it come complete with 4 heads ?? thank you

Hello,

I’m highly interested in the dual set-up to print support PVA, and I’d love to pre-order it, but my question becomes what slicer or program to use to achieve this?

Thank you,

Alucard

Can you recommend a soluble support material to use with solid filaments in the dual extruder model?

This^^^^^

Would be damn nice to have this ability!

I am wondering how much it waist on changing the colors! Could be a down fall! Is there anymore videos on this

Hi,

I would like to pre order the multi material add on for my mkII but i am no sure which one I should order. So I think most of the time i only need 2 different materials so is it possible to use the quad one but then use only 2 most of the time?

many thanks

Hi Mathias,

yes, you can upgrade to quad, but use only two extruders (actually any range from 1 to 4). It all depends on your settings in Slic3r.

I write for German speaking people.

Habe am 22.08 2013 den Drucker Prusa i3 MK2S zusammengebaut erhalten. Die Firma Prusa kann betreffend Kundensupport mit 5 Sternen bewertet werden. Alle Fragen zum gekauften Drucker wurden noch am gleichen Tag beantwortet. Ebenso wurde ohne Probleme und Verzögerung meine Bestellung vom KIT zum FERTIG Drucker eingeleitet. Der Postweg dauerte bis in die Schweiz 5 Tage und ist somit top. Ich habe aus Zeitgründen erst einmal die Box / Packung geöffnet, die Art der gepolsterten professionellen Verpackung ist aufwendig und aufgeräumt. Angst vor Transportschäden durch Postversand, sind bei zusammengebautem Drucker dadurch nicht gegeben. Ich kann diese Firma in jeder Beziehung weiterempfehlen. Melde mich wieder wenn Drucker in Betrieb und der Multicolour-Ausbau eingetroffen ist .

Gruss aus der Schweiz von Werner

Sehr geehrter Herr Peter,

Vielen Dank für Ihre positive Rückmeldung! Sollten Sie auf Probleme stoßen oder ein paar Tipps zum Drucken brauchen, zögern Sie nicht zu fragen 😉