During the coronavirus pandemic, dentists have been among those who put their health on the line. At work, they literally stare right into the potential infection source, and obviously, their patients could hardly wear face masks.

When dentists use their drills and other rotary tools, they need to cool those down with a constant flow of water. This water mixes with air and the patient’s saliva and/or traces of blood into a potentially infectious aerosol. Like a hardly visible light mist, the aerosol could travel as far as 8 meters from the patient’s mouth!

Lukas Pekarek, the founder of Asana-dental, came with a simple but ingenious solution – the Asana suction system.

The suction head is put near the patient’s mouth and traps the aerosol right at the source. Heavy water droplets still sprinkle around, but that’s not such a big problem, as they fall down quickly and cannot be inhaled.

From the very beginning, Lukas closely cooperated with a medical professional (which is the only way to go when designing any medical equipment, really). Dr. Vit Payma, a dentist based in Pilsen, Czech Republic, gave him perpetual feedback on how to fine-tune the design for practical use. The final product immediately met with huge demand.

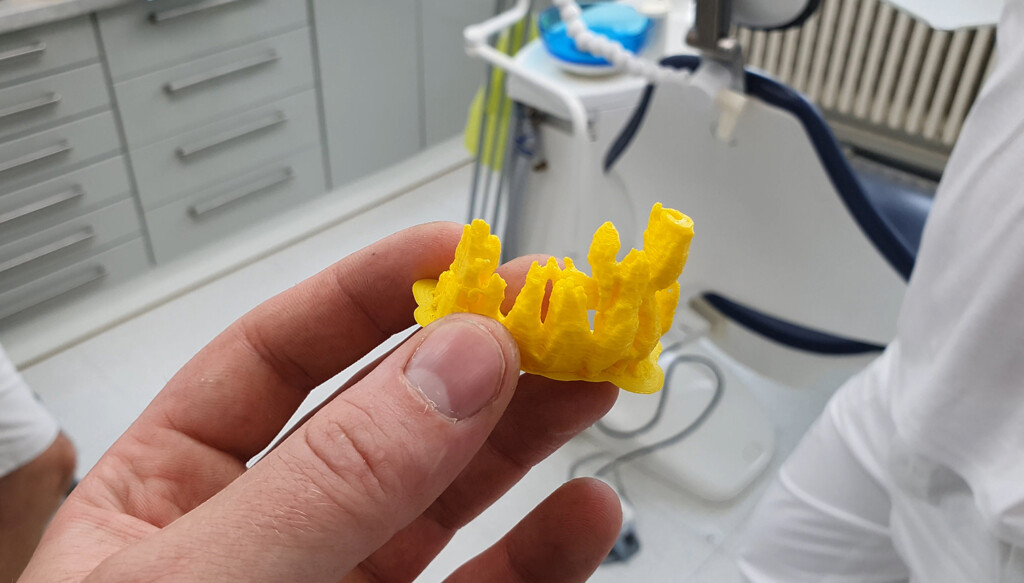

On an interesting side note, Dr. Payma is a skilled 3D printer user himself. He uses CT-scans to print models of teeth and jaws for a pre-op assessment. As he says, a real 3D object is always better than an image on a screen and helps him better prepare for the more difficult procedures.

The Asana system consists of a handful of parts made with various technologies: the articulated hose is regular injection plastic, the magnetic holder is FDM printed, and the adaptors on both ends of the hose, and the suction head itself, are SLA printed.

It took some time before an ideal shape of the head was found. Some of the earlier design iterations didn’t hold in the patient’s mouth on its own and had to be held by a nurse. All the initial design iterations were FDM printed (on Original Prusa i3 MK3S), but these prints couldn’t be properly sterilized, because of the prominent print layers and low heat resistance. For the production version, Lukas switched to SLA, using Original Prusa SL1. The suction heads are made of a special resin, bio-compatible, and heat resistant enough for sterilization. He started with the Formlabs brand and later switched to 3Dresyns. It is worth noting here that while a Formlabs printer would only accept a Formlabs resin, the Original Prusa SL1 could print from a vast selection of 3rd party materials.

As for the hose adaptors, Lukas tried a regular tough resin first, but that was just too brittle, and then a flexible resin, which was too soft. He came up with an unorthodox, yet rather obvious solution. To get the best of both worlds, he mixed the two resins together and averaged their exposure times. Well, this goes against all the usual recommendations, but if it works, can we really complain? 😉

Dr. Payma adds: “I really like that the whole system is modular, easy to disassemble, and if we want to further improve the design, Lukas can implement the changes very quickly.”

Website: asana-dental.com

You must be logged in to post a comment.