You’ve surely noticed our brief overview of filaments in the handbook sent with your printer. While that is still a very useful source of info for beginners, advanced users might want something more elaborate. That’s why we’ve prepared the advanced filament guide that summarizes all supported filament types found in PrusaSlicer.

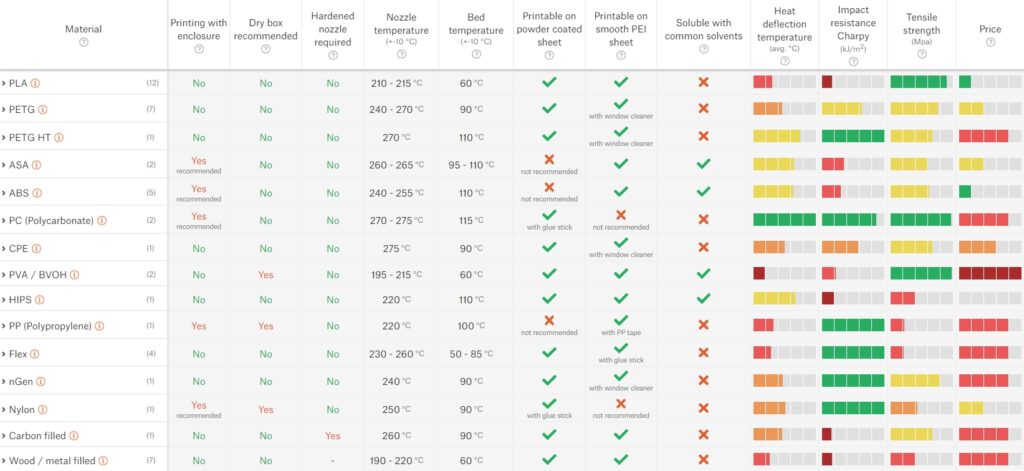

Let us introduce our material table that allows you to compare the basic parameters of different filament materials and brands. This way, you can decide which filament is the most suitable for you. Clicking on the material name will open a text with all necessary information about usage, print preparation, postprocessing of that material, and photos of sample models. If you want to skip the table and get straight to those texts, you can find them here: PLA, PETG, ASA, ABS, PC, CPE, PVA/BVOH, HIPS, PP, Flex, nGen, Polyamide, Composite materials, Carbon filled.

But now let’s return to the material table. It features not only basic information such as temperature, recommended print surface, and various mechanical properties, but also the price of that particular filament. For materials, these values are shown only on a scale from 1 to 5 but after clicking on the filament material, you’ll find exact values for supported brands.

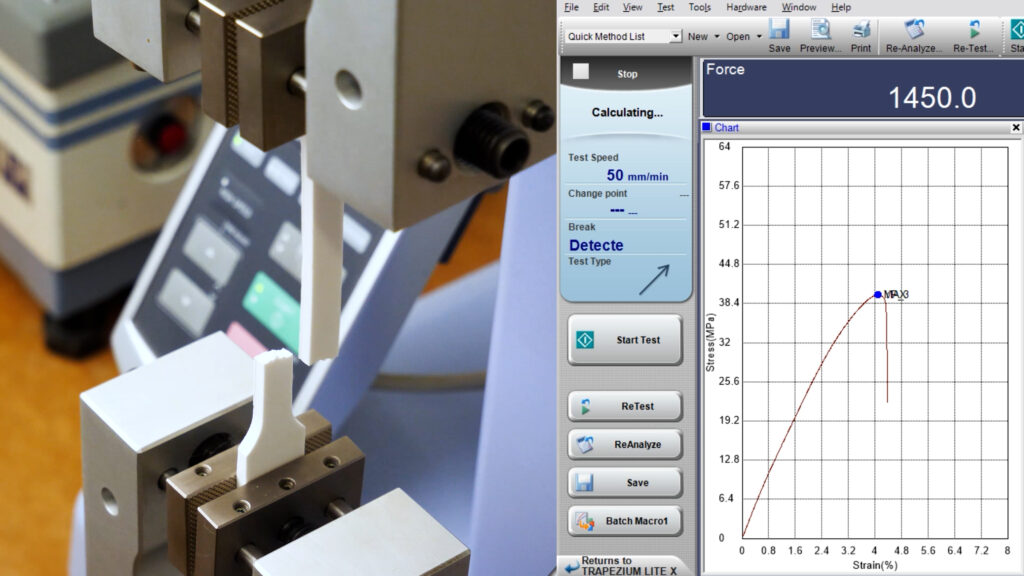

To make the comparison as valid and meaningful as possible, we tested every filament by ourselves, using the same method. But keep in mind that even with our greatest effort, these values might not be 100% accurate and some datasheets might show different (more accurate) results.

If you are interested in specific filament parameters, you can filter these values. Every parameter can be sorted by clicking on it. Plus, you can filter filaments by selecting various attributes such as mechanical resistance, chemical resistance, flexibility, etc.

Long story short – with our filament guide you’ll never again hesitate whether the selected filament is suitable for your needs. We believe that it will help you avoid a lot of trouble and extra costs. Go ahead, have a look at our guide and let us know how you like it, what could we change and improve. Do you miss your favourite filament? Let us know! Your opinion will help us to maintain and improve the guide so it can be helpful for as many people as possible.

Happy printing!

I think you should include the excellent filaments from https://addnorth.com/en/

I would like to see the very good filament from your neighbors 3DKordo

https://3dkordo.pl/everfil-przeglad/

thanks

Hmm… PLA doesn’t want to stick to smooth PEI unless glue stick is used, while PETG is totally fine without any glue/window cleaner. Anyone else have the same expierence?

Hi,

When I use PLA it sticks very well to the smooth PEI sheet, but you need to clean it with above 90% isopropyl alcohol. Otherwise your PLA could come loose.

Hello, it’s good to clean smooth PEI sheet with 90%+ isopropyl alcohol. If PLA doesn’t stick even after cleaning it this way, you may try to clean it with window cleaner, then again wit 90%+ IPA. PETG sticks very well to smooth PEI sheet – it sticks too much to be precise. Using window cleaner or glue stick for PETG is recommended to lower the PETG adhesion. Otherwise, it might damage your sheet.

I experience that as soon I change from PETG to PLA My bed adhesion is not the greatest. Maybe some residue is left inside the extrusion path.

PLA sticks very well to the smooth sheet but after much trial and error I have found that washing the sheet with dish soap, hot water and then drying it off before every print has me a guaranteed print. I stopped using alcohol as sometimes that would not work in places. The soap and hot water has been faultless.

BTW, why PLA/PVA have 2+ for heat deflection? Shouldn’t it be closer to 0? What filament do you expect to have a zero score?

You are correct, it should be closer to 0. We’ll fix it asap. None of these filaments should have a zero score. For temperature resistance, it would mean that it gets soft at room temperature.

You probably want to change the “Warping” column to be more clear. Right now it looks like “X” is bad and “✓” is good like in the other columns, but what you mean to show is “no warping = good” and “warping = bad”.

You could either change the “X”s in the column to “NO” in green text and the “✓”s to “YES” in red text, or you could change the “Warping” column title to “Avoids Warping” (or something like that) and swap the “X”s and the “✓”s so that PLA has “✓”s and ABS has “X”s.

Either of these options would make it clear that warping is undesirable. Good chart otherwise!

Hello, you are right, It’s fixed now. Thank you for feedback.

You’re welcome, good idea to call the column “Printing with enclosure”! I think this will be really easy for people to understand.

Hi, Apart from the scale of 1…5 used in the Material table would it be easier to read if a legend is included for the colors… did we get the sequence right? green, yellow, orange, purplish-pink, maroon (somewhat similar to the forum page; at the bottom all icons with relevant text)

Hi,

the material table looks quite good with the detailed information of the specific manufacturers. The information I am missing is the Modulus of elasticity for each material. since you already have done the tensile strength tests, you should be able to calculate the elastic modulus. This would add the information how flexible the material is. As the tensile strength only tell when it breaks it is not possible to compare with others. For example PLA has high tensile strength, but it feels like it breaks much faster then PETG. An additional information – elongation at break would then cover all material properties. With these information it would be possible to do static analyses with the materials to check for specific parts which material is the most suitable.

PET-G and PLA are soluble in d-limonene?? Only partially probably. (Acetone and alcohol don’t work on them).

For PLA we have found that only DCM can fully dissolve it. MEK only softens it.

In any case it would be good to mention the type of solvent and the temperature in which the plastic will be solubable.

Hello, PETG and PLA aren’t soluble in d-limonene. PLA can be partially dissolved in acetone but it will more likely disintegrate the model into tiny flakes instead of making slurry like ABS.

It is true that solubility differs with various temperatures but that requires a lot of testing and would cover another whole article (and table). This table mentiones only which filaments can be dissolved (smoothed) at home.

Thanks for the reply Jakub, I appreciate the effort. We are 3D-printing windturbines in which different parts are welded together chemically. We have done tests with PLA and acetone but it’s really unworkable. If the solvent doesn’t make homogenous slurry, smoothing won’t work either.

(Please check www.fromwastetowind.com for more)

Btw, we registred with a username ‘fromwastetowind’, but we are displayed as “in-124”. Can we do something to resolve this?

Hello, we’ve fixed this issue. You can edit your name now as you wish (I already see you as fromwastetowind).

Very useful table and good idea!

In the manual an other sources for the Powder coated bed, there is written that if glue is applied, there occur micro cracks in the coating, but for pc you recommend to use the powder coated sheet with glue, what is correct now?

What is for different print surfaces which are only rarely used? For example I use also steel plates with buildtak which are great with ABS and PCmax or kapton and printed also with interesting results on glas ceramics (robax) with an aluminium tape for the z homing.

But for those special cases I don’t except you to do some research, just as feedback that there are users with other solutions.

Hello, it is not necessary to apply glue stick on the powder coated sheet for most filaments. Only two exceptions are Polycarbonates and Nylon.

Yes, I know. That’s the question, because it’s mentioned that glue and or acetone will produce small cracks to the material in this blogpost from you: https://blog.prusa3d.com/how-to-print-on-a-powder-coated-sheet_30178/ so I wonder why you recomend glue on the textured PEI Sheet. (I like the sheet very much).

Are there any plans to cover more ‘exotic’ filaments like Taulman range with PCTPE and alike?

“2pcs aluminum tube diameter 7.8 mm (from original spool holders)”

Which “Original Spool Holder” and where can i get this 7.8mm Tube?

Hello, I think you are asking in a wrong thread. Anyway, I think you are talking about spool holders that come with mmu2s kit:

https://help.prusa3d.com/en/guide/7-spool-holder-and-buffer-assembly_46160

7.8mm tubes might be also available at your local hardware store.

In the table, when you filter by UV resistance only ASA is shown. Shouldn’t PETG and ABS be included as well?

You should add EasyABS and ABT-T since it’s a little different from normal ABS.

And specially since it’s one of the ABS-filaments you sell

Is it possible to test Extrudr Greentec and Greentec Pro?

Is there a quick way to make this printable so I can keep it with my other printer information? The printer and my computer live in different places. When I tried to print, it only wanted to print a couple of columns.

Can anyone confirm that I am reading the Materials table correctly? When it says “Dry box recommended” set to “No” for Prusament PETG, does this imply that Prusament PETG does not absorb moisture? Conventional knowledge on the Internet suggests PETG absorbs moisture and must be stored in a dry box. Can we get an official response from Prusament experts on this?

I think it would really help and improve if you add a stiffnes rating or youngs modulus at the table because that’s what I miss. Because I would like to find the best and most stiff Material for my voron 0 which has also a certain Heat capacitiy.

Is it possible to add rigidity (Young’s Modulus) to the table? You should be able to do it with existing data sets and its another important material property.

I agree that a drybox isn’t needed for PLA if you’re printing high volumes of the stuff, but I strongly **disagree** with the “no drybox” recommendation for a hobbyist who has several spools of PLA, each of which may take more than a year to use up. I have found that a drybox is mandatory for long-term keeping, especially for those “silk” PLA filaments, which cause nozzle jams if they get too saturated with moisture.

My Prusa printing sheet says satin powder coated sheet. Do I look at the column labelled “satin” or “powder coated” on the table?

I’m new to 3D printing. So new that I have not yet even received my 3D printer yet. While I wait I was looking at the Material Table. PETG HT caught my eye because of its impact resistance and Heat Deflection temperature. Unfortunately when I select information, it just goes to PETG. I’m not even sure what the HT stands for, or if it can be purchased.

Can anyone help?

The Materials Guide Table is certainly very useful. But due to large numbers of manufacturers, of course it is only a representative sample. It would however be handy to see a greater representation from some more manufacturers. There are some big names missing I suggest PolyMaker products could be added, because their TDS documents are easily available, as well as those from Spectrum. And, because of their prevalence if not quality, then at least one of eSun or Sunlu should appear, although I grant that the information in the table is harder to obtain for those products.

A fun one to add would be ProtoPasta products, because of their novelty which goes to innovation, something I suggest ought to be encouraged.

Where did the material table go? Now it gives me 404 not found error.

Please add Ethyl Acetate to the list of relatively safe solvents that can be used at home. It is even more safe than Acetone, and used in food industry as a flavour solvent (E1504 food additive, https://www.food-info.net/uk/e/e1504.htm).

Also take into consideration that in some countries it is nearly impossible to find chemically clean Acetone because it is prohibited as a precursor for drugs production. For example, in Ukraine all that one can find are so called "Acetone+" and "Acetone D", i.e. Acetone with some unknown crap mixed in, which may affect the strength of post-processed ABS or ASA.