We’ve previously manufactured some cool composite materials and they were a big success: we prepared materials suitable for mechanical use, such as the Prusament PC Blend Carbon Fiber and Prusament PA11 Carbon Fiber. To make the next step, we decided to make a highly advanced metal-filled filament aimed for technical use rather than aesthetic purposes: we’re launching Prusament PETG Tungsten 75%! While this material is primarily designed for a very specific group of users, we believe that its development will intrigue everyone in the 3D printing community. This filament has a lot to offer – its non-reactive, hypoallergenic and non-toxic properties make it ideal for various medical applications. Additionally, its high density is perfect for creating complex radiation-shielding components in an easier and faster way compared to conventional methods. Let’s talk about it in more detail.

Tungsten, also known as Wolfram (chemical symbol W, atomic number 74), is one of the heaviest metals in the periodic table. With its density of about 19 grams per cubic centimeter, it is comparable to gold and it is about 1.7 times denser than lead (chemical symbol Pb, atomic number 82). Because of its atomic number, tungsten can be used in various applications as

x-rays and gamma-ray radiation-shielding material. It is a mostly non-reactive element that does not react with water, oxygen, or with room temperature air. Unlike lead, tungsten is hypoallergenic and non-toxic, which makes it perfectly suitable for medical applications.

Materials with such high density are generally very difficult to machine, can be very expensive, or even toxic. These materials’ inherent properties make the classic manufacturing methods undesirable. Additive manufacturing provides the potential to create complex/individualized shielding components more easily and sometimes at a reduced cost.

Radiation shielding and mechanical properties

The Prusament PETG Tungsten 75% is filled with tungsten powder (75 % in mass), thus it obviously does not have the same shielding properties as pure tungsten. We made the following table to clarify the shielding properties of Prusament PETG Tungsten 75% compared to pure lead and tungsten. To understand the table, we need to explain some basic terms used in the radiation shielding industry:

Density (g*cm-3): When considering options for radiation shielding, the most important characteristics are the material’s atomic number and density. Lead and tungsten are the most common materials to shield against x-ray and gamma radiation, that’s why we compare those two (pure) metals with the new Prusament.

Linear attenuation coefficient (µ): This is a constant that describes the fraction of attenuated incident photons in a monoenergetic beam per unit thickness of a material. The higher the linear attenuation coefficient, the greater the substance´s attenuation capacity, representing a more suitable shielding material.

Half-value layer HVL (mm): In radiation shielding characteristics, the half-value layer (HVL) is an important parameter to talk about. It represents the thickness of the material at which the intensity of radiation entering it is reduced by one-half. For the most commonly used gamma-ray energy in nuclear medicine imaging (140 keV, 99mTc) pure lead has an HVL of 0.256 mm, tungsten comes with an HVL of 0.191 mm. In other words: you need less tungsten than lead to get similar shielding results.

| pure Pb | PETG Tungsten 75% | pure W | |

| Density (g*cm-3) | 11.3 | 4.0 | 19.3 |

| Linear attenuation coefficient (140 keV, 99mTc) μ (cm-1) |

27.11 | 4.95 | 36.23 |

| Half-value layer HVL (mm) | 0.256 | 1.402 | 0.191 |

| Multiple of pure W HVL | 1.34 | 7.34 | 1.00 |

Comparison of radiation shielding properties between Prusament PETG Tungsten 75% and common shielding materials. The linear attenuation coefficient of pure lead and pure tungsten was calculated using the physics.nist.gov database and values in this article.

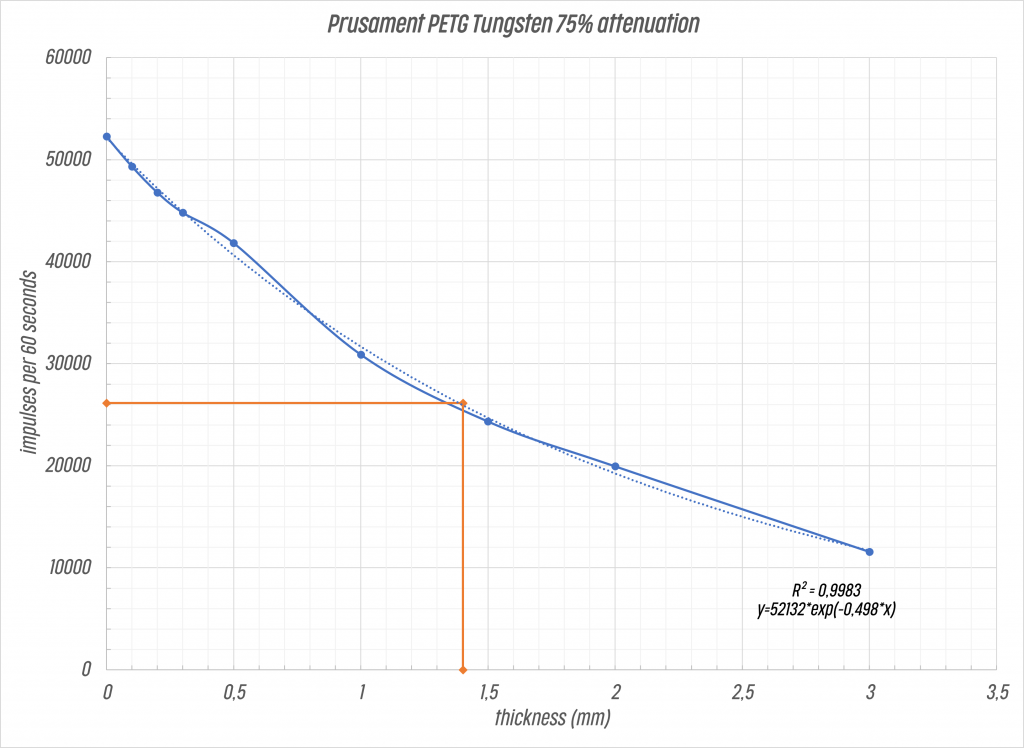

The results shown in the table (density, μ, and HVL) are theoretical for pure lead and pure tungsten. The Prusament PETG Tungsten 75% density (4 g*cm-3) was calculated from the mass and dimensions of the filament. Its μ comes from the series of attenuation measurements led by Ing. Jaroslav Ptáček, Ph.D. in the department of Medical Physics and Radiation Protection at Olomouc Hospital. The HVL value was then easily calculated from the experimental data.

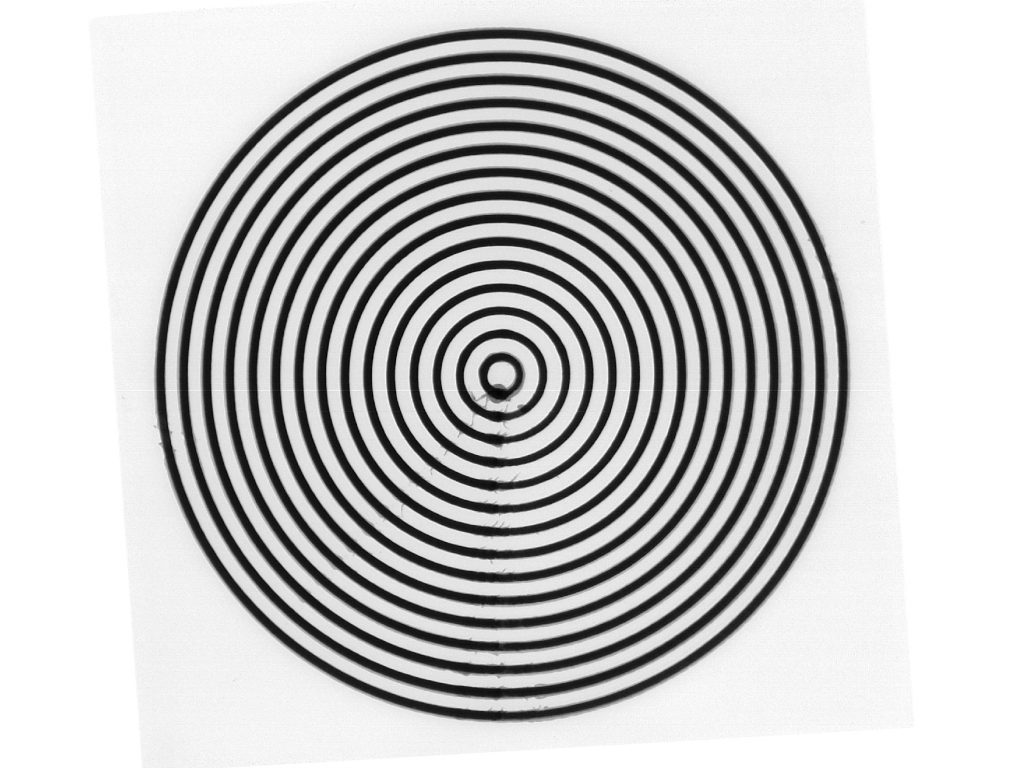

Prusament PETG Tungsten 75% testing apparatus. The radioactive emitter is not seen in this photo.

Measurement method

All measurements were done with metastable Technetium (99mTc). During the attenuation measurements, the Prusament PETG Tungsten 75% sample of a certain thickness was irradiated by a source of radioisotope 99mTc. The attenuation of a particular sample was established using the narrow beam geometry. In nuclear medicine diagnostics, it is the most commonly used medical radioisotope. Used as a radioactive tracer, it emits detectable gamma rays with a photon energy of 140 keV.

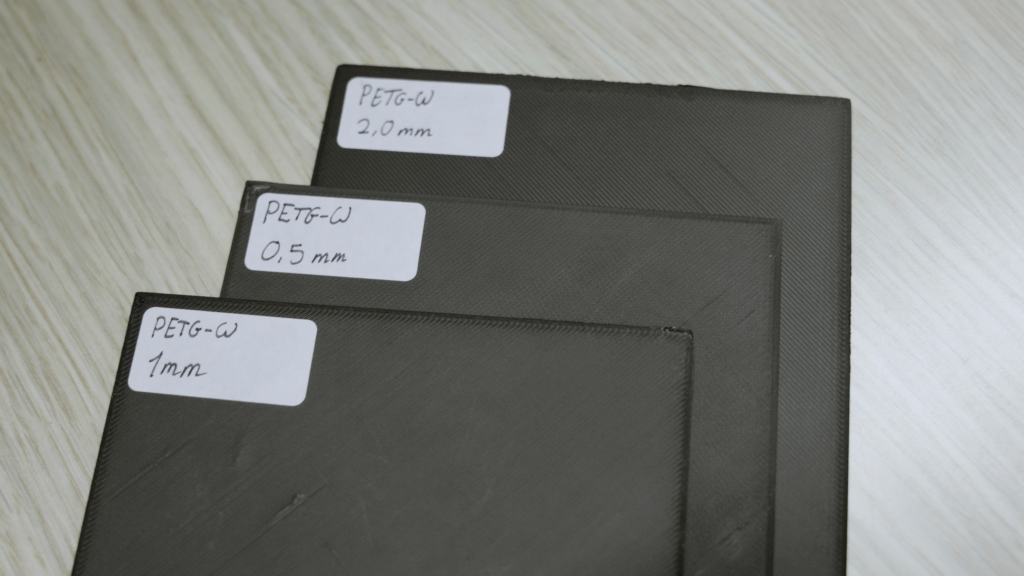

Some of the tested Prusament PETG Tungsten 75% samples.

The test objects were 3D printed with Prusament PETG Tungsten 75%, with the following thicknesses: 0.1; 0.2; 0.3; 0.5; 1; 1.5; 2; and 3 mm. The measurements were taken perpendicularly to the surface of the sample. After taking the measurements, we calculated the HVL (see the results below).

Inserting the metastable Technetium (99mTc) inside the testing apparatus.

Attenuation measurements results. The Y-axis shows the amount of gamma radiation passing through the tested sample, the X-axis represents the sample thickness. The calculated HVL for Prusament PETG Tungsten 75% is 1.402 mm (orange mark). For comparison, the HVL for pure lead is 0.256 mm, HVL for pure tungsten is 0.191 mm.

The Prusament PETG tungsten 75% can be printed with a 0.4 mm nozzle with no fear of clogging, which often occurs while printing metal-filled filaments. We bonded the tungsten fine powder with PETG due to its good printability, resistance to radiation and chemicals (for example various disinfection solutions). Complete mechanical and radiation shielding properties can be found in our technical datasheet but here are the most important parameters:

- Pure tungsten shielding properties: HVL of 0.191 mm (99mTc, 140 keV)

- Prusament PETG Tungsten 75% shielding properties:

HVL of 1.402 mm (99mTc, 140 keV)* - Bonding polymer: PETG

- Tungsten content: 75% in mass

- Charpy impact strength: 22 kJ/m2

- Tensile yield strength: 39 MPa

- Shore hardness: 79D

- HDT: for 0.45 MPa 94.2 °C; for 1.80 MPa 86.0 °C

- Hardened nozzle needed: Yes

*As observed during material testing, there are many factors influencing the overall results, such as 3D printer condition, slicing, etc. Thus the shielding properties of your prints might slightly differ.

Note that the Prusament PETG Tungsten 75% print profile is not included in PrusaSlicer, please download the Config bundle (MK3S+) here. If you need a print profile for another Original Prusa 3D printer, contact our support and we will gladly help you out.

How does it work in practice?

We tried to make a proof of concept with a shielding apparatus for syringes used with nuclear medicine radiopharmaceuticals. We’ve used the Prusament PETG Tungsten 75% for printing a desired part with a thickness of approx. 8 mm thick shielding, which is equal to 5.7 HVLs (based on 99mTc). This apparatus was designed specifically for the radiopharmaceuticals infusion system used at Olomouc Hospital in its laboratories. With our 3D-printed part, the hospital staff can switch between more syringe shieldings.

Prusament PETG Tungsten 75% printed shielding

Although the 3D-printed shielding was significantly thicker than the pure tungsten, that is being used commercially, the 3D printing was significantly faster (considering the ordering, transportation, etc.). In some cases, ordering spare parts may be too complicated and the Prusament PETG Tungsten 75% may help in creating a suitable substitute. This shows great potential in various rapid repairs and improvements in radiological instruments. And finally, in some parts, additive manufacturing can save not only time but money too.

Price, color and weight

Usually, we make filaments in various colors for aesthetic purposes. However, technical materials, especially metal-filled and carbon-filled are generally colored by the fine powder inside the polymer. That’s why our tungsten filament is colored only in dark metallic grey. The standard spool contains 1 kg of material, which equals 100 m of filament. But besides that, we also offer 100g samples containing approx. 10m of filament. Please note that due to the high amount of tungsten, the overall volume of the material is significantly lower. The price for 1 kg of material is 229 USD / 249 EUR (VAT incl.), the 100g sample costs 23.99 USD / 25.99 EUR (VAT incl.).

Calibrate your printer with our tool before printing large and heavy parts

Please keep in mind that you need the printer in the best condition possible. Any clogging or other flaws lead to worse radiation shielding properties. Although we can’t guarantee that you’ll get exactly the same values as we found in our testing, we may help you to get the best results possible. For this, we designed this calibration block that should weigh at least 5.4g, when printed. We recommend printing it and weighing it before you start creating large and heavy parts. This way you can find out whether your printer is in the best condition that is necessary for successful printing with Prusament PETG Tungsten 75%. If you see any flaws on the block or find that the weight is significantly lower than 5.4g, clean your printer thoroughly and repeat the process. Finally, we recommend testing your prints to find out the exact HVL, just as we did with the metastable Technetium.

A comparison of two 3D-printed blocks, the left one represents a well-calibrated printer, the one on the right shows under-extrusion (possibly a partly clogged nozzle).

Typical applications

As for the best use, we designed the Prusament PETG Tungsten 75% partly for medical applications (for example radiology) but we are aiming for the whole radiation shielding industry. There are a number of areas where radiation shielding filaments may be used. This includes for example the aerospace, nuclear energy industry, non-destructive testing, x-ray imaging devices, etc. We understand that the Prusament PETG Tungsten 75% isn’t designed for the community as a whole but rather for specialized research and high-end engineering use. We believe we’ll see many fantastic shielding parts designed and printed by you very soon. If you have any ideas that may involve our cooperation, please let us know. We’re always eager to try something new!

Any idea what the shielding performance is for MHz to GHz spectrum?

In my field of use, radioactivity is not really an issue. However, EMI/EMC shielding certainly is.

Then this is not what you are looking for. You should use a properly grounded finely meshed enclosure of a highly conductive material (e.g. copper).

I have found ABS-EL ESD filament to work well in shielding GHz frequencies:

https://www.3d-printerstore.ch/ABS-EL-Filament-ESD-21kg-175mm-conductive-schwarz

Damn the cost is high… for now I’ve been using copperfill for X-RAY imaging markers and letters but it had to be encased as it was reactive.

Interesting that by mass it is 75% W, but by volume it is about 1/7 or 15% metal. Amazing the density differences between polymer and metal.

Thank you for making this! We have been very thrilled with all of the new material releases such as flexible resin, CF-PETG and now this filament. This is one of the many reasons we are a devoted customer – Prusa Research is awesome! Can we request that you start making mango yellow ASA?

Just to confirm, this does not require any extreme temperature sintering, like other tungsten filaments on the market do, right? How would you say the layer adhesion and brittleness of the material compares to regular PETG? I don’t know how to read all the figures in the spec sheet 😅

I’ve been interested in the idea of 3d printing brass instrument mouthpieces, but my results have so far been pretty poor. In part I think this is because of poor impedance matching caused by the very low density of common 3d printing plastics compared to that of the instruments (wasting a lot of energy and muffling the sound). So I have been on the lookout for high-density composite filaments that are more or less safe to touch with your lips for prolonged periods of time. I’ve previously eyed the “Filamet” line of filaments from The Virtual Foundry, but they are allegedly extremely brittle until you sinter them. Obviously having access to a sintering furnace is far beyond what a hobbyist can hope for.

If this filament is indeed stable enough to use without any such post processing, it could be a viable option for me.

Hello,

This filament indeed doesn’t require sintering. In fact, it is unsuitable for this method of postprocessing.

It’s significantly more brittle (impact strength 22 kJ/m2) than pure PETG (100 kJ/m2), I would compare it to Prusament ASA (25 kJ/m2).

I’m afraid we haven’t tested the acoustic properties so I can’t tell if it would actually sound better… 🙂 But you can try the 100g sample to determine if it works.

Thank you for your reply 🙂 I think I will give the sample a try!

Tungsten is very hard, so I would expect a hardened tungsten nozzle (at least) to be required !

Surely a normal brass nozzle would wear out very rapidly ?

Please add to this article: Information about the nozzle required for printing tungsten filament.

There is already a mention of the necessity of using a hardened nozzle. It’s true that the brass nozzle would wear out rapidly but you don’t need a tungsten nozzle – the regular hardened steel nozzle (or nozzle X) is enough.