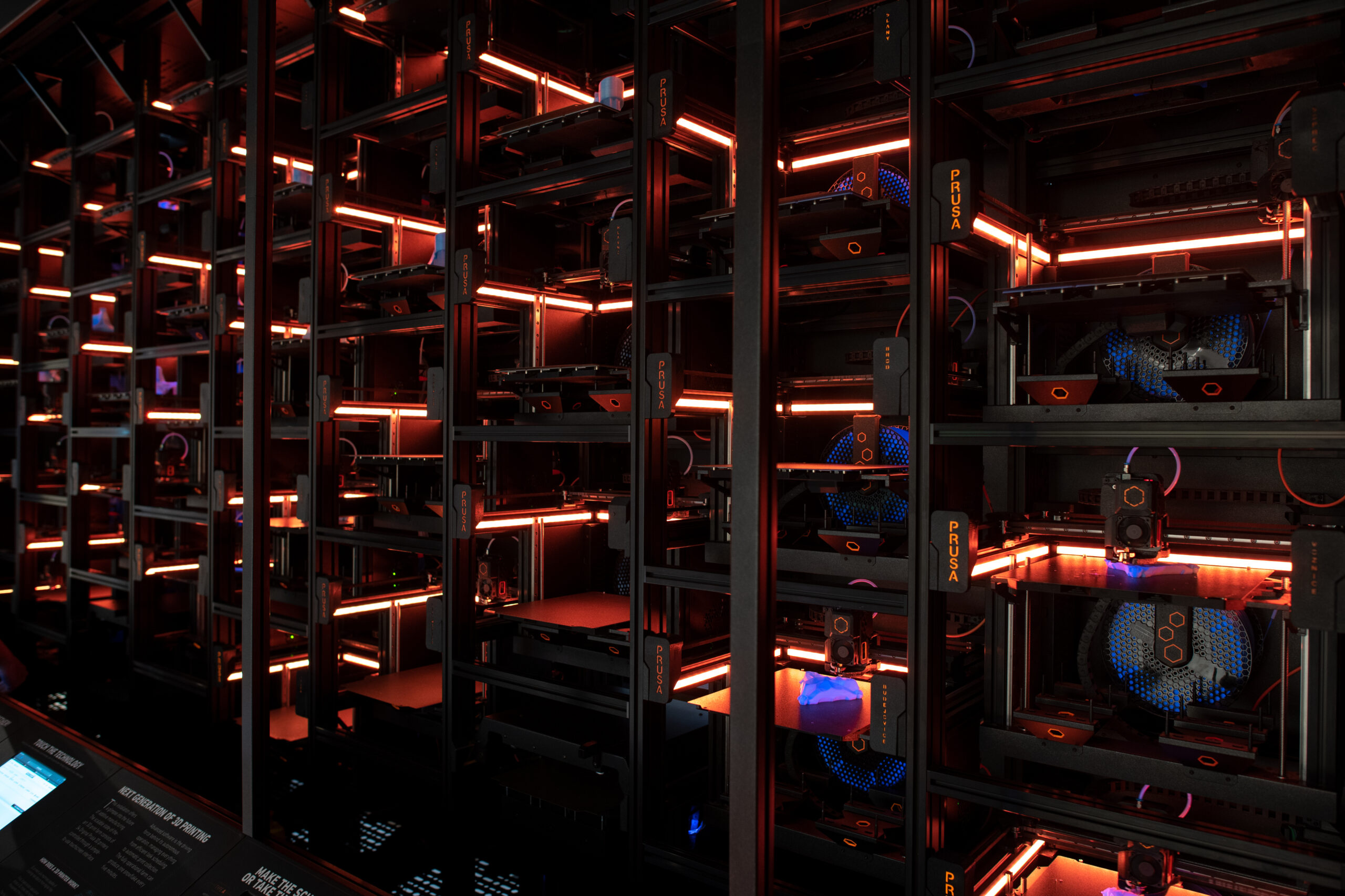

As you probably know, we run a massive, sprawling 3D print farm in our HQ in Prague. Six hundred 3D printers run 24/7 to produce plastic parts for new machines. Everything is expertly maintained and managed by our skilled farm operators. However, we always wanted to automate the production, yet there has never been the opportunity to do it. This changed about three years ago. We were approached with the idea to represent Czechia at Dubai’s EXPO 2020 – provided that we would have something “next-gen” to show. It was the right opportunity to dive headfirst into our plans for our new 3D printing farm.

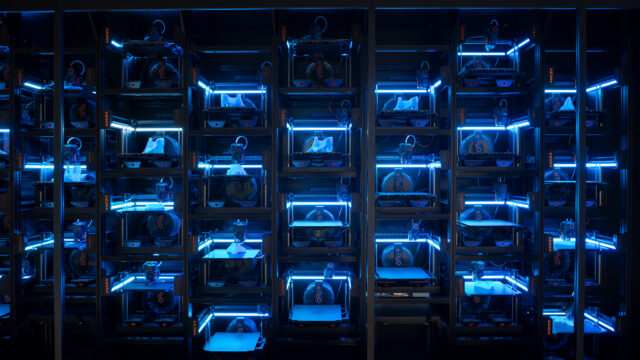

We started assembling a new team and the work kicked off. Now, we can finally show you the result: An automated 3D print farm of 34 new Original Prusa 3D printers, internally developed farm management software, and automatic collecting and delivery systems. The best way to experience this next-generation production facility is to see it yourself in Dubai. However, if you can’t get there, I can give you a quick virtual tour!

Prusa Pro AFS – Automated Farm System

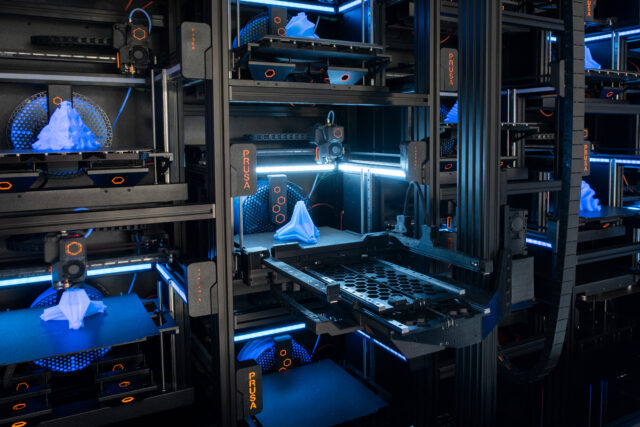

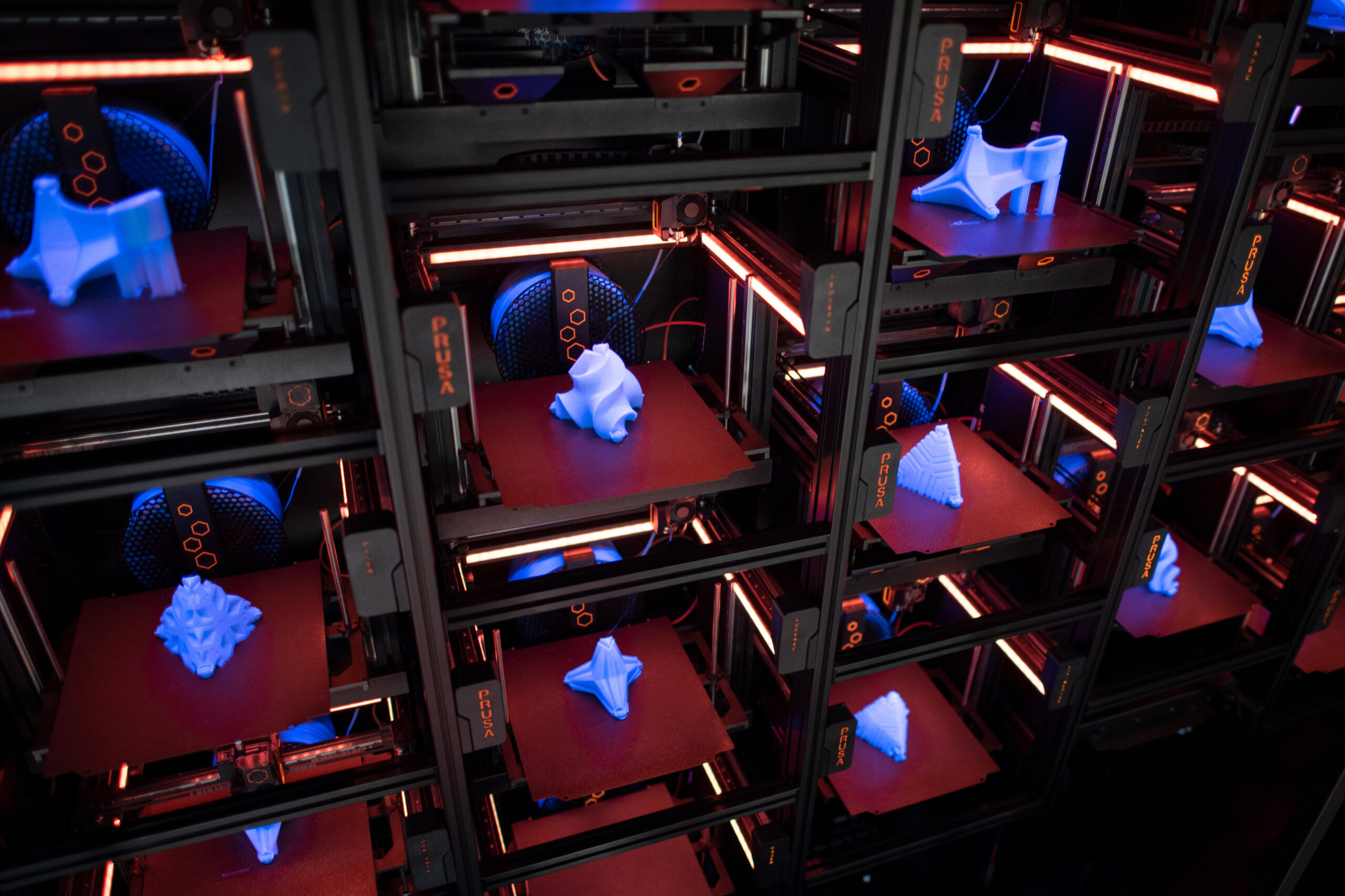

The farm in Dubai consists of 34 new CoreXY Original Prusa 3D printers. And while these are not the expected “Prusa XL” printers exactly (they are smaller and there are no tool-changing options yet), they share certain features and technologies. To make the print farm space-efficient, we decided to use a cube-shaped frame, so the entire farm is similar to a computer server rack with hot-swapping capabilities; when a printer needs to be serviced, you just slide it out and put a new one in its place.

And yes, that even means that you can scale the farm according to your needs, the number of printers is not fixed. In the future we plan to have multiple sizes and variations too: let’s say you can run 10 printers with tool changing setup, along with 50 regular size single-material ones in one farm. There will also be different options for unloading the parts. The farm at the expo is simply putting all the prints into two bins, but unloading the whole plates for QC/traceability pipelines is in the works too.

Our new software called Prusa Connect controls everything: when you select a file to print, it finds the best machine for the job automatically (e.g., a machine that just finished printing and is not fully cooled down yet, so getting back to operating temperatures will be faster and more efficient). Prusa Connect keeps track of all print jobs, statistics, remaining time, and other crucial settings and statistics. Once an object is finished, the software automatically sends a mechanical arm that lifts the print sheet, moves it towards the collecting area where the object is detached from the sheet and delivers the part to the collection bin. The print sheet is then returned to the printer. By the way, you can check out a beta version of this software for yourself by signing up for our closed beta test right now.

The Future of Manufacturing

We see our automated 3D print farm as the future of manufacturing – especially for small-batch production. It requires little to no maintenance and operating the printers is easy-to-learn, making onboarding new employees quick – the farm management software does the majority of the work and keeps the costs down. The environmental impact is another significant area: there’s very little waste (compared to machining or other subtractive technologies), you can manufacture products locally so you don’t need to deal with transporting them from one place to another, and recycled materials are in the works too. Of course, our 3D printers can work with a wide range of materials – from PLA to Polycarbonate blends, ensuring you can find the right polymer for your product’s needs.

We already have customers running print farms with dozens of MK3S+ or MINI+ 3D printers – the Prusa Pro Automated Farm System is the next step forward.

So, what are our plans for the future? First of all, the automated print farm in Dubai is a fully functioning prototype. At this point, our production is still severely affected by the worldwide shortage of various parts. This has a strong negative impact on our release schedules and we’re not ready to jump into full production. Our next step is to run the Automated Farm System locally (in our regular print farm) for several months and put it under as much stress as possible. However, we are ready for your inquiries: if you are interested in getting our print farm for your business, or if you have any questions or specific requirements and requests, please get in touch! Our plan is to deliver the first units to our customers within the next year. Pricing is not determined yet, but it will vary according to the farm size. With larger farms, we are aiming for 3000USD per printer + service contract.

From the small amount of feedback we received, we already have a number of potential use cases:

- Big campus universities love it – students send their prints into the queue, supervisors can review the data and approve the print which gets sent into the farm.

- The same applies to big engineering firms requiring efficient machines for research and development.

- Companies that have to keep large numbers of replacement parts for warranty purposes for many years. With materials like PC Blend, it is definitely possible to provide a large amount of the needed parts – and produce new ones easily when needed.

- In-house low-volume manufacturing, especially interesting if you want to customize every single item produced.

- Automated print-on-demand service providers.

This article is just a small taste of what we have in the works. I have deliberately skipped detailed technical specifications for now. Since these machines share certain parts with our yet-to-be-announced devices, I have to keep a lid on the details. Rest assured that we’ll share more information soon. 🙂

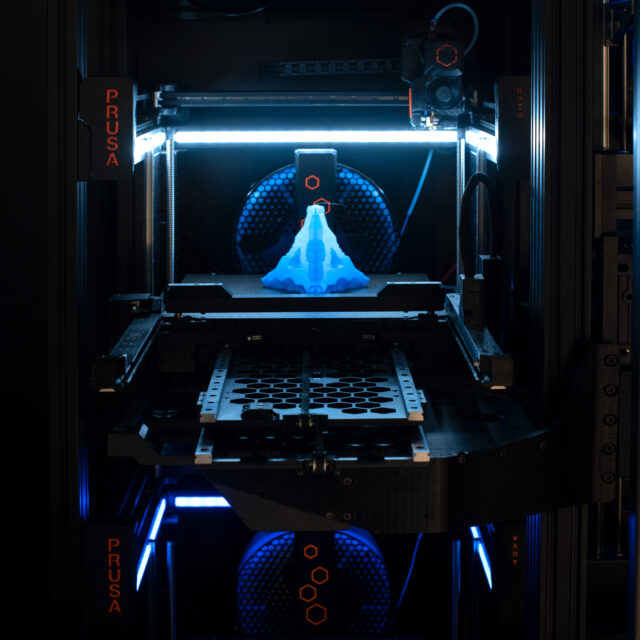

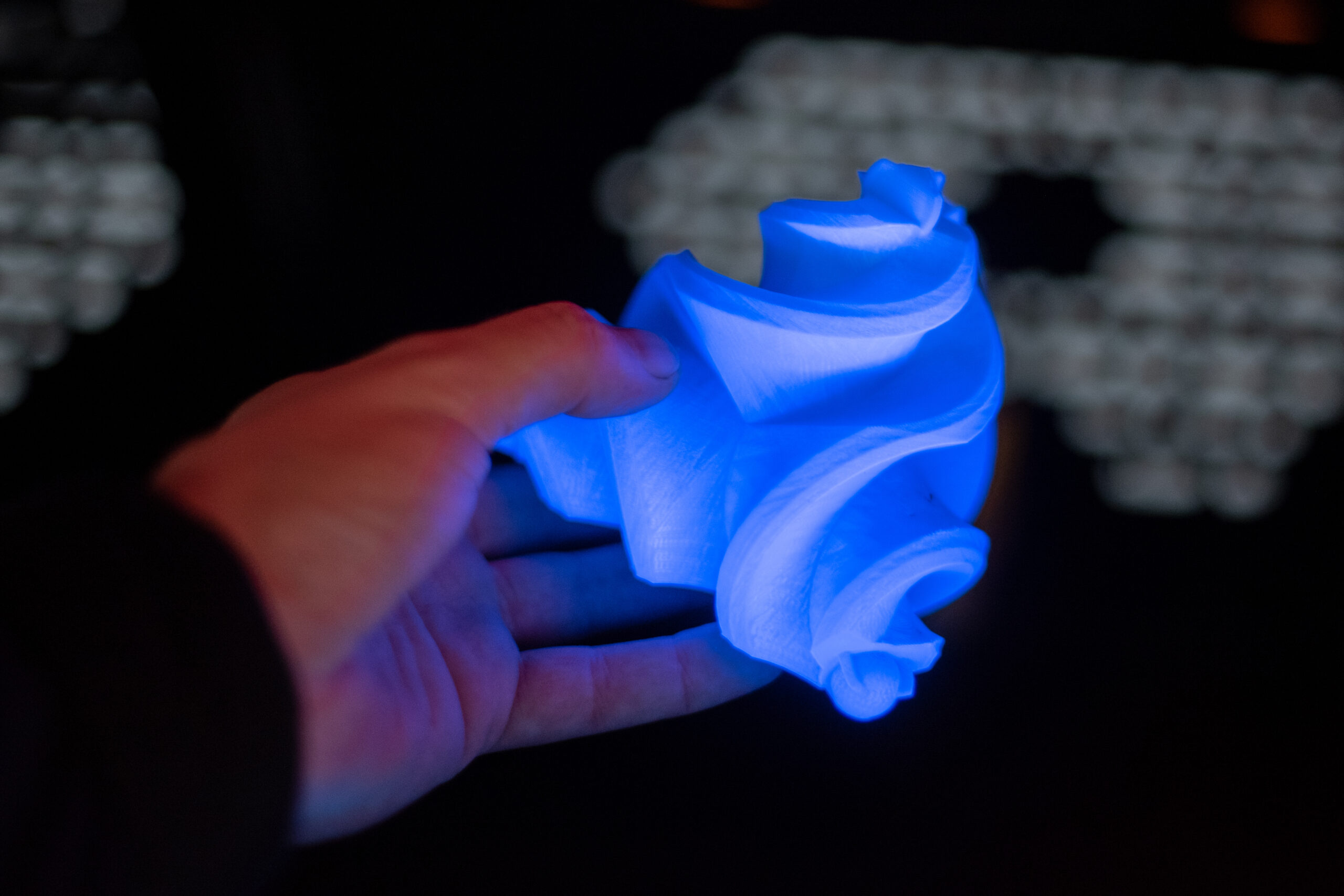

Snowflakes in the Desert

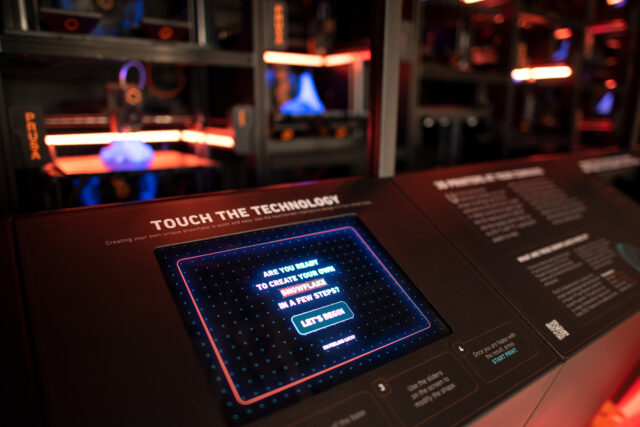

Our exhibit at the EXPO 2020 is interactive – visitors of the show can use a simple touchscreen interface to upload print jobs to the farm. Of course, we do not expect people to bring G-Codes. 🙂 Instead, we prepared a cool little app that allows users to design their own unique snowflakes and have them printed from fluorescent PLA. Why snowflakes? Well, first of all, they bring a nice contrast to the hot climate of Dubai, but more importantly, they perfectly demonstrate the power of 3D printing. Every snowflake is different, so producing them using injection molding would be either nearly impossible or incredibly expensive. Not so with 3D printers where one-offs and customization come easily.

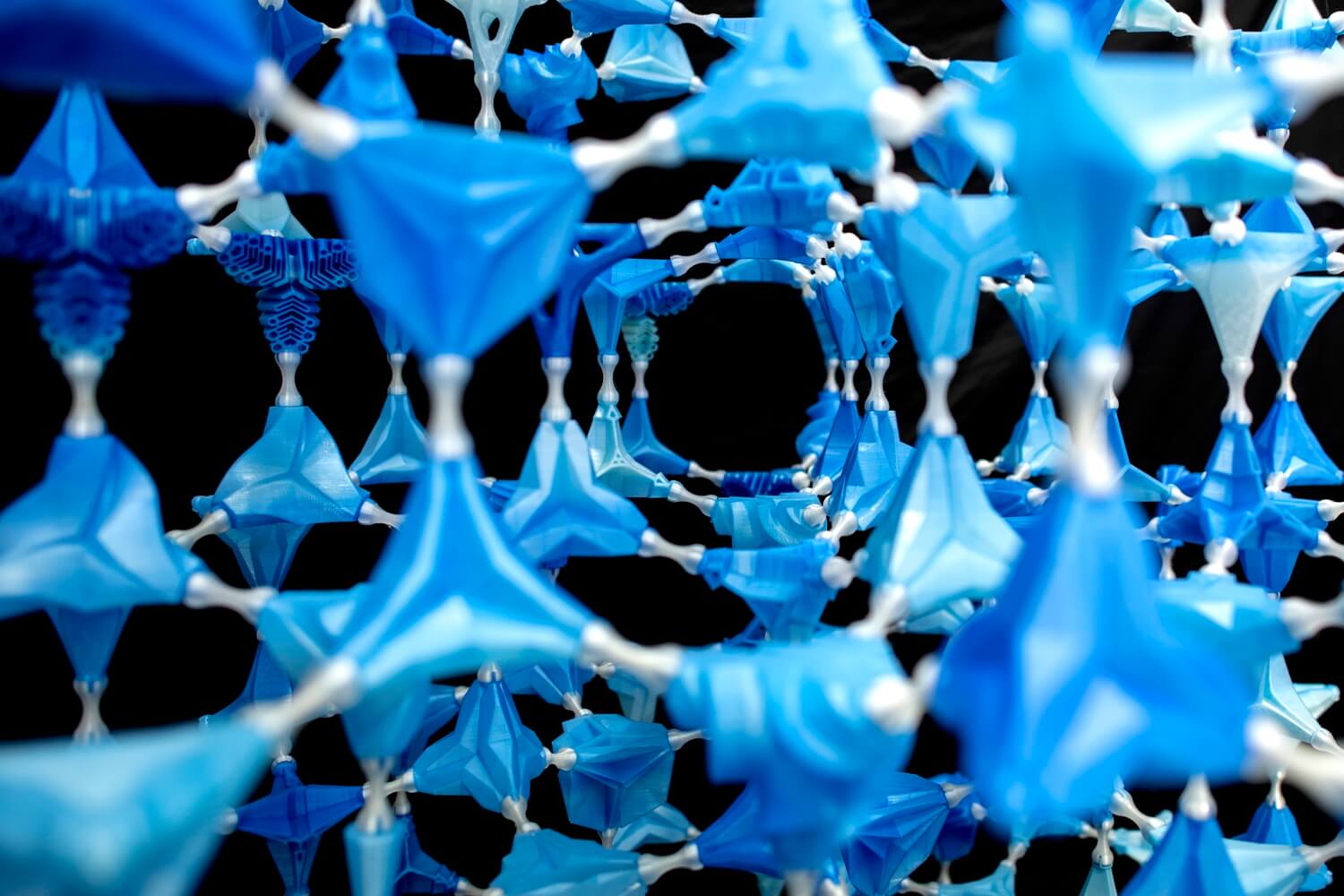

So you’ll simply design a unique snowflake, upload it, and an available printer will start working on it immediately. It’s that simple. The visitors can then take the 3D-printed snowflakes and add them to a dynamically growing sculpture, which is also a part of the exhibit.

Even if you can’t make it to Dubai in person, you will be able to create your own snowflake from your home. We are working on the web version of the snowflake app, which will be available at https://expo.prusa3d.com/ within a few days. If you want to be updated about the whole project, follow us on Twitter, Instagram, and Facebook.

We’ll be happy to see you in the Czech pavilion at the EXPO 2020 – the gates are open till March 31st, 2022!

Beastly. Very nice concept.

Brilliant! I can’t wait.

Amazing to see your strive to become a “Maker of the Future”!

Even if i am “only” a private user of 3D-Printers, i am excited to maybe see some of the design elements shown on this project for the future XL and other soooooooon to be released printers.

Great job everyone at Prusa, love to see your progress!

Greetings from Bavaria,

Stefan

Interesting, but I’d be happy with prusa connect and dozen prusa mini with wifi

Can we get enclosures for the MK3s similar to the ones shown direct from PRUSA?

That looks awesome, I’d like to see it in action.

Waiting to buy the XL, but nice to see progress. Also nice to see that you use the new e3d Revo nozzles. You can see them if you check the high res pictures. What I also saw is that you have A few failed prints, and on one picture you didn’t hide the stabilized power supply and Linda probe behind the booth.

Since a long time, I was not this excited for a new product

Those are not Revo hotends.

I’ve heard Joe Prusa say that the printers in these units would be pretty similar to the upcoming XL :O I’m stoked!

Nice to see! The small spool on the back is not ideal, we use 5kg spools and place them on top of the rack. Would love to use the “normal” prusa printers as a farm with the new farm software.

Congrats to Jo and the amazing Prusa Research team! This is a very intuitive way to run a print farm and it looks so good too. You guys once again delivered something mind-blowing and I just can’t stop looking at the pictures.

If your last last product launches are anything to go by.. best wishes to the first buyers! LOL “only some users are affected” “all printers do it” marketing spin left right and center, always to be expected here at prusa.

3000$ a printer PLUS a service contract…..

You seem to have forgotten your roots…..

Never pass up an opportunity to criticize someone’s success! Make sure everyone stays in their “box.”

Apple and HP should shut down everything and move back into their garages. Facebook and Google should shutter all facilities and move back into their dorm rooms.

The price for the XL as stated previously will be around 1200-1500. 3000 for a professional, industrial, modular farm printer isn’t very much for a company that can deduct it as an expense.

Look at it from the bright side, none of the prices above comes even close to the nonsensical prices of for example Ultimaker.

That farm system looks amazing. I’m looking forward to see more about it. Has anyone found any videos to see it working?

TBH for something that clearly targets businesses and other large-scale commercial users 3k and a service contract doesn’t seem particularly expensive or unusual…

Wow, that is one hell of an integrated solution! Looks like Prusa is stretching it’s wings from a hobbyist market to a integrated manufacturing market. Just please don’t forget about us little guys!

Just want to add—love the rack-mounted, plug-n-play function.

Great to see some real progress beeing done by Prusa. If you look closer, this whole setup looks like Prusa is improving on the Voron design with hopefully a good extruder implemented right from the start. Can’t wait to see some high-res pictures in good lighting of one of these printers 😉

Well, both these new printers in the farm and the future PrusaMEGA share a design feature with the Voron printers in that their positioning system is CoreXY. But that isn’t a new feature, nor pioneered by Voron. Other than what one would expect from a bog-standard CoreXY, what features of the Voron do you see Prusa improving on?

Disclaimer: I’m not that familiar with the details of the Voron offerings, so I don’t know what they offer beyond what one would expect from the bog-standard CoreXY platform. So, I’m asking out of ignorance, not trying to call you out on anything.

I wonder if these smaller form-factor CoreXY printers will ever be offered for individual sale by Prusa, or if these are just implementation of their engineering test bed for learning how to design and control CoreXY positioning systems that they knocked out quickly (using the MK3 print-bed and extruder?) just for this demo.

it is a very innovative and natural progression for a progressive company like Prusa. Great Job !! Looks sharp with a space saving design and ease of use.

I would hope that the same technology can be used by diy Prusa fans too with small budgets.

Prusa Connect UI looks awesome but I cannot seem to find clear instructions for Prusa Link extension on the link page to add my MK3S+ machine? Can you please help? Thanks.

Can we at least get an idea around when the XL will be available?

It will be released Friday. They told us this 2 Weeks ago.

Glad to read this amazing post.

I love your year end of the year emails. I forgot about this post and I got to read it more thoroughly. It makes me excited for the next i3 sized printer. Maybe open up a beta program like the guys at E3D? LOL