Here is my awaited status update on the Multi Material Upgrade.

I am very sorry but I am postponing shipping once again because of an unforeseen issue of finding out that the vast majority of filaments around are out of spec. I will give you more details in a bit but firstly I will shed some light on the Multi Material Upgrade development history as I believe it is long overdue.

Initial release

For the initial proof of concept and early demo units, we went with the E3D V6Lite hotends. Compared to the full E3D V6’s found on all MK2’s we ship currently, the Lite is fully lined with PTFE and does not have a separate heatbreak. This allowed us to quickly assemble and prototype our multimaterial upgrade. They worked great and we went ahead with the press releases!

Moving to the full V6

My early test of the concept (shown in the original release article) used full E3D hotend so there was no reason to expect it will cause troubles when putting in the final product as users already have the full V6 in their MK2s. We initially succeeded with addition of ramming to the change routine. Ramming means extruding out all the molten plastic before pulling the filament out.

Later on we found out that not all E3D heatbreaks are created equal and some are not as polished as advertised and have a burr on the entrance. It does not affect normal printing performance by any means but if the heatbreak is affected beyond certain level, it is not possible to get the color changing reliable. The filament gets stuck when entering the heatbreak. We alerted the E3D about some heatbreaks with the burr rendering the opening to be 1.9mm or rarely even smaller and their response was, that it would be too expensive to make standard production heatbreaks as nice as we would require them.

If the heatbreak is re-polished and deburred it works pretty reliably. However it makes it very prone to bending they need to be manufactured properly from the beginning.

Delay #1 – dealing with the heatbreaks

We decided that downgrading the printers to the V6 Lite is unacceptable and our devs tried to engineer around this issue so no users will have to change the hotend.

We arrived at a solution pretty quickly by adding precision 1.85mm stainless steel tube into the multiplexer. When a filament is pulled out it cools down with 1.85mm diameter and doesn’t have a problem entering even 1.9mm heatbreaks. Filaments are made 1.75mm +-0.05 so everything will fit nicely, Awesome!

Delay #2 – marks on the filament

Obviously we found another problem introduced by the precise tubes. With a lot of retractions the stock hobbed pulley marks some filaments sometimes enough to prevent the filament to go through the tube causing a jam. Not all filaments are affected and we didn’t find out straight away. This is no problem for regular MK2 as the retracts are normally very short.

Vojtech (our Slic3r magician) got and idea to use the Bondtech drive gears to preserve nice and shiny filament. It worked and we’ve decided to update all the MM upgrades to Bondtech geared hobbed pulleys. We placed an order with 6 weeks lead time. The first batch arrived two weeks ago so we have all the parts to ship everything.

Unfortunately at that time we found out yet another issue.

Delay #3 – filament

Our team and external beta testers were very lucky with the first tests and the filaments. But spending more time on this, the truth is no filament we’ve tested is good enough for the 1.85mm steel tube. Majority of spools from every manufacturer have little defects with larger diameter. You normally never experience issues with regular printer as the 1.75 hotends are drilled out to 2 mm.

There is no way around this. Especially if you would want to use the filaments you already have and mix spools from manufacturers. There is always a little imperfection somewhere inside jamming the precise tube. Moreover with 4 materials, you use 4 different spools. If only one of the 4 spools has a small imperfection, a print is ruined.

What’s next

We need to modify the design, so the printer accepts all filaments, including those with diameters out of the declared manufacturer’s range. Our next step is to order larger 2mm tubes and modify heatbreaks to accept the 2 mm.

We are also waiting on a special high tolerance PTFE tube from FESTO to replace the one normally shipped with V6 to aid the filament dead center into the heatbreak.

My team and I are waiting for all the parts, which might take up to 3 weeks. With some more testing we can optimistically start shipping in April.

Recap

I do understand that it has taken too long and I am deeply sorry that I have to announce another delay, I completely understand if you don’t want to wait any longer and will issue a refund to anyone who asks for it.

There is still no one even attempting to do what we have done here with 4 materials so thank you for your patience and happy printing.

To the rest, thank you for your understanding, I cannot push it out the door just yet as I want to give our customers the best experience with the Multi Material upgrade as they have already received with the MK2.

- 2 Colors Wall Street Bull by Dizingof

- 2 Colors Wall Street Bull by Dizingof

- Hairy Lion (dual extrusion) by _primoz_ is licensed

- Model with selective soluble support

- Hairy Lion (dual extrusion) by _primoz_ is licensed

- It’s a plane

- Sheeps and Homer

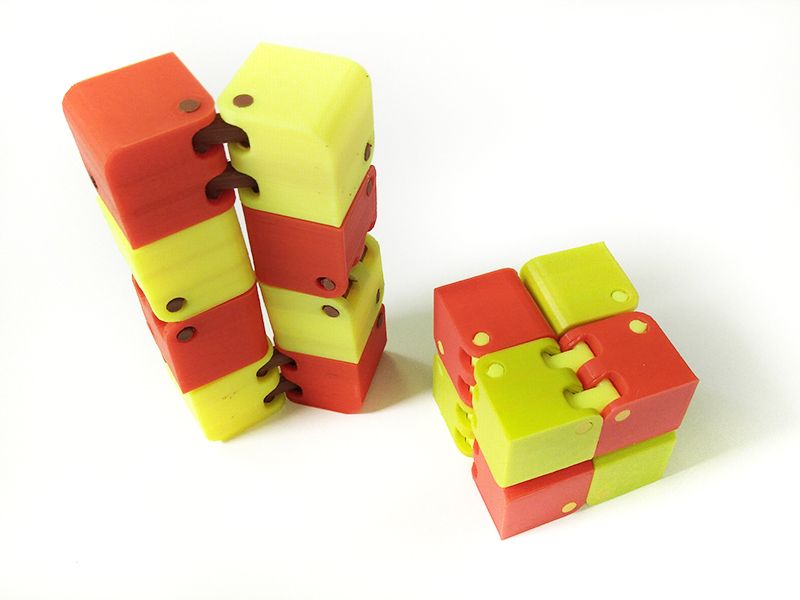

- Kobayashi Fidget Cube by pkobayashi

- Demon Girl Bust Dual Extruder by KingRahl

Better to work out the kinds sooner than later. Thanks for the update. Perhaps you can also use the time to work with the most popular slicers to program an option to use dumped color change waste as infill?

Yes this would be very nice!

Take the time you need to design it as excellent as the mk2! Thank you!!!

Great to hear some news, please keep us informed!

It’s terrible how out of spec these filaments are, and time that the makers got their acts together, no wonder people keep having jams and things! It’s time all the printer makers put pressure on them to up their game!

The results so far are looking good!

Sometimes the only filaments that are completely within a manufacturer’s specifications is their proprietary filament at twice the price. I’ll risk an occasional reel of junk in order to keep the other 95% cheaper.

Is there an official supported dual head option around? 4 materials is cool but just main material and support material would satisfy a lot of needs in the short term and take the pressure of a bit.

At the risk of drawing ire from all of the above… making the annoucement last year and taking orders and $$s on an unproven product was imprudent. I bought in last November and based that on statements that the product was essentially ready to go. I love my MK2. By far the best of my 4 printers. This situation is very disappointing.

Best wishes,

Frank

Frank,

I do believe you said what many are thinking. Thank you for making it a tactful comment and not unloading your frustration in pointless foul language.

No ire intended here… but surely that is better than sending you product not fit for purpose like many company’s do and then charge you for the upgrade fix.

I disagree that Prusa in November said it was ready to go in the sense you imply. BETA testing is clearly mentioned and the explanation here shows that the delay was introduced as a result of active engineering and quality control by Prusa

I agree the situation is disappointing but it is refreshing to know that this is driven by customer care and professionalism on behalf of Prusa. You could be sitting in front of printer with a sub-standard product pulling your hair out!

Just saying…

I agree and look forward to a very cool 4 color machine. Best wishes for its successful launch!!

Seriously, as a customer why did you not email this news to me? Do I really have to scour your websites and forums for news of a product I have paid for?

Dedication to quality – this is great to see. I will wait, no problem at all. Thank you.

Josef, thank your for the update and you honest transparency in regard to the situation. The process of quality 3D printing is and has been a tricky horse to ride. I am extremely happy with the Prusa products we have, the support and of course your investment in making the i3 Mk2 an upgrade-able device.

To this end I’m happy to continue with leaving my order on back order until as such time that you and your development team are happy with design at the Prusa quality I have come to expect. I am in no doubt that Prusa expertise will find a solution and we will get a working quality upgrade.

Thank you

I’m very please that you come out with an explanation of why things take longer.

Usually companies think it is a bad move to be honest (which in the end never has a good result).

I’m a machine designer myself and I know what it is like to design something and you think you have a fine working machine and there keep popping up problems.

But it is always better to have them in the testing stage instead of when everything is shipped already.

I think I can speak for all customers when I say that we would like a good quality machine to enjoy for years to come. So please take all the time you need to perfectionate the design. You still have my vote of confidence!

(Just don’t go bankrupt all the sudden =) )

I decided over great debate to cancel my order. I will probably regret it. I would rather put the money towards a second I3 MK2 as it would be more beneficial then a multi-material extruder.

I have the same thing to say as nearly all the comments so far – stick with the detail work, and in the end have a superior product. period! I also believe that, as this is a tech product for ‘techies’, nearly everyone will have a great deal of patience, as most of us have experience with ‘around the bend’ projects – where new challenges arise as visible milestones happen – then, an altogether new challenge appears – rinse, lather, repeat! So long as the process remains transparent, I’m pretty sure that we all have sufficient patience to see this through to the end…

No problem, Last week the MK2 arrived as a kit. The quality is perfect, the shipping, the instructions, etc! Just perfect. Just some calibrating issues, but that is the fun of buying a kit.

Keep the standard high Josef, you are doing a great job. I will wait

Frans

Would it be possible to already release the mounts for the extruders (stl)?

I would love to print these as an upgrade for my printer 😀

A lot of other manufactures would have shipped the the defective product and some would even charge for the “upgrade” to make it work. Congratulations on being one of the “good guys”. Keep up the good work.

I’ve had my MK2 for about 4 months now and recommend it to anyone who asks.

Any news about the MMU?

Have the 1st been shipped or are there any delays?

I’m willing to wait for the update until you are ready to ship, but I’d like to be informed about updates.