New firmware 3.4.0 for Original Prusa i3 MK3 and MK2.5 is out! We usually inform about firmware updates in short chapters within larger articles, but this release has so much new stuff, I decided to tell you more about it. Plus, I would like to share updates related to powder coated steel sheets availability and our shipping table.

One of this firmware’s major features is the support for Multi Material Upgrade 2.0, but I have already covered that extensively in my previous article. Let’s check out some of the other features instead.

Filament Sensor Engine 2.0

One of the major new features of Original Prusa i3 MK3 printers is the presence of a filament sensor. This little electronic board keeps track of the loaded filament and allows for such features as filament auto-loading, stuck filament detection or pausing the print when you run out of material.

Now, the part of the software responsible for analyzing the filament flow has been completely rewritten to improve the precision and reliability of the sensor. It means that the sensor can recognize filament runout with greater accuracy and the number of false detections drops significantly. In the past, MK3 and MK2.5 printers shared the same values for the evaluation process, which sometimes led to incorrect results. Firmware 3.4.0 fixes this issue.

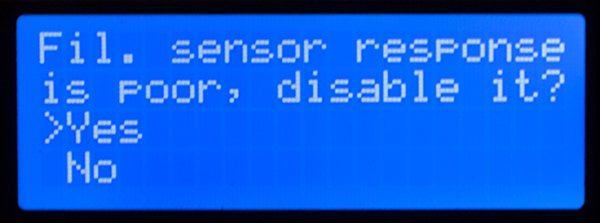

But the Filament Sensor Engine 2.0 can do much more. Thanks to the infrared sensor, we can now properly scan the surface of the filament. Our software can evaluate the measured values and analyze, whether the printer can reliably control the filament flow or not. In case the sensor can’t ‘read’ the filament movement properly, an on-screen message appears, informing the user that the filament quality is less than optimal. In addition, an option to turn off the sensor is displayed.

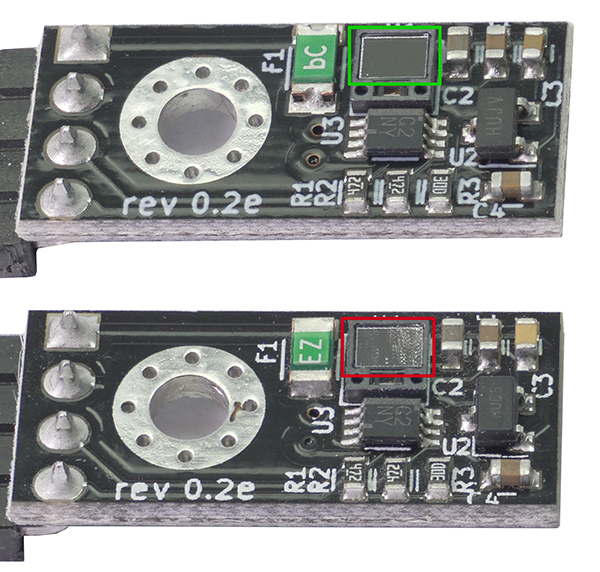

Keep in mind, that the filament sensor’s precision is affected by any dirt that may accumulate on its surface. Clean the sensor from time to time using compressed air – the extruder has a hole precisely for this purpose. See the picture below to compare the clean and dirty sensor.

Improved power panic for MK3

Another important feature of MK3 is the power panic/blackout protection. Basically, when there’s a sudden power outage (or you trip over the cable by an accident), the printer is able to store the last position of the extruder and once the power is back on, the printer can continue printing where it previously stopped.

It worked pretty well, but there were some cases, where the current code wasn’t enough. In case of several consecutive power outages, the restoring process would be interrupted and the print could fail. Also, in the case of a very short power outage (less than 50ms), the print could also fail. The new firmware fixes both these issues, making the power panic mode more reliable than before.

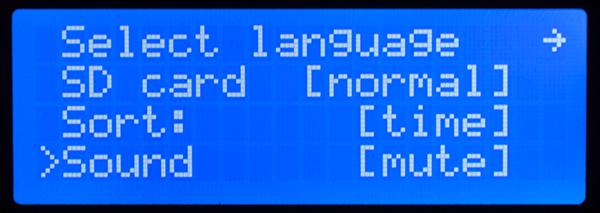

Adjustable beeper notifications

We always prided ourselves on the fact that our 3D printers are super silent. And now they can be even more silent – we have added an option to modify the beeper settings. When you open the Settings menu on the LCD screen, you can choose from four sound presets:

- Loud – Failure and user input notifications

- Once – Same as Loud, but beeps are played only once

- Silent – Only error notifications

- Mute – Complete silent, no matter how serious the error is

Improvements of feedrate and acceleration limits for MK3

To decrease the load on the printer’s CPU, we have introduced further optimizations for feedrate and acceleration values. Up until now, the feedrate and acc values were compared to hardcoded limits with every movement throughout the entire print. In the new firmware, the checks for G-codes M201 and M203 are performed only at the beginning of the print. If the input values are smaller than hardcoded values, no action is triggered. In case the values from G-code are greater, the firmware replaces them with the default (hardcoded) ones.

Current limits for the MK3 in the firmware:

Stealth mode:

feedrate 172 mm/s

acceleration 960 mm/s^2

Normal mode:

feedrate 200 mm/s

acceleration 2500 mm/s^2

G-code M42 is back!

This is a great addition for anyone, who wants to create beautiful timelapses of their prints. Basically, the M84 M42 G-code can write or read a pin on the mainboard, which can be used to trigger a camera’s shutter.

The whole setup is a bit complex, since every manufacturer uses a slightly different trigger mechanism (voltage), so the best way is to solder a custom cable. Don’t worry, we’re working on that and we’ll have a comprehensive guide for you in the near future.

Minor tweaks and fixes

As usual, the new firmware brings a number of minor tweaks and important bugfixes. Starting with firmware 3.4.0, you can easily diagnose the status of the P.I.N.D.A. probe by going into the Calibration menu and selecting Show P.I.ND.A. state (MK3 only). If you take a metal object (such as a screwdriver) and put it close to the P.I.N.D.A. probe, you will see the indication going from on to off based on the proximity of the metal object.

Also, the Linearity Correction menu returns with the 3.4.0 firmware. To learn more about this feature, please visit our Knowledge base.

DOWNLOAD FIRMWARE 3.4.0 FOR ORIGINAL PRUSA i3 MK3/MK2.5

Shipping table updated

After 14 days of shipping, we are finally ready to set up MMU 2.0 estimates in our shipping table. Now you can easily find the week of your order and estimated shipping time. Follow us on Twitter for more info about the shipping table updates.

Powder coated sheets status

Powder coated steel sheets are kind of a never-ending story. We have already managed to send a few thousand printers (lead time for new orders is 3 weeks now), but we still don’t have enough powder coated sheets to offer them for separate orders.

Our suppliers are still not able to hit the quality point we demand. We are still returning a high percentage of sheets back to the supplier, which causes further delays. Currently, we estimate that we could start selling powder coated sheets as separate orders in the second half of October. I know that we have postponed the delivery a couple of times already, but we don’t want to send anything less than perfect to our customers.

For the reasons mentioned above, we also decided to step away from the plans regarding the production of glossy powder-coated sheets. Maybe we’ll come back to them sometime in the future.

So, that’s all for now. If you will be in New York next week, don’t forget to visit the World Maker Faire 2018! We will be there for the whole weekend (September 22 & 23) and believe me, we have prepared some exciting announcements for this show.

Happy printing!

Jo Prusa

All great news…. I’d give anything to be able to buy spare smooth PEI steel sheets never mind the powder coated version…

Hi Phil, you can buy it here, just make sure you are logged in the eshop.

shop.prusa3d.com/en/mk3-printer-parts/216-spring-steel-sheet-smooth-pei.html

Hello,

I have a Prusa i3 Kit and it does not work. It has never worked.

I got my kit about three years ago, and would like to use it.

I am not on Facebook and do not want to get on there.

[email protected]

Hi,

first check the assembly according to the online guides https://manual.prusa3d.com/c/English_manuals If you are sure, it is assembled correctly, please contact our support at [email protected], my colleagues will help you 😉

I would be cautious with regards to using compressed air to clean the filament sensor. I used it on my sensor and broke the mirror on the board. I prefer to use a micro fiber cloth. Only takes a moment to slide out sensor and wipe off the mirror.

I started having problems with my MK3 repeatedly pausing during prints, with prints sometimes failing due to extrusion stopping. Working with tech support I isolated the problem to the filament sensor system. Disabling the sensor or disconnecting it stops the problem. I upgraded the firmware to 3.4.0 but the problem is still there. In the meantime I’m running with the sensor disconnected.

I just upgraded to the 3.4.0 firmware. Wow! What a difference. Right off the bat issues I had with some of the different filaments auto-loading or false indications of filament loss seems to be much better.No hits do far. Also, I never was able to get the underside of the Frog file to print clean. There was always some stringing. It is now perfect. Best firmware upgrade I have ever installed on the i3 MK3.

I installed the new fw version, and loaded some Prusa orange Prusa PETG. I immediately got the “Fil. sensor response is poor…” message. I used some compressed air to remove dust. Same message. I unmounted the sensor and found some dust on the sensor surface. Is there any recommended procedure for cleaning it? Isopropyl alcohol on a cotton swab? I used a clean cotton swab without alcohol.

Got the same message after remounting it.

Maybe the sensor is too advanced?

Hi Dag,

try following:

1) Remove the filament and clean it according to this step

2) Update to 3.4.1 which has improved the filament sensor sensitivity https://www.prusa3d.com/drivers/

Cool! Thanks

Will check firmware, and glad to see that MMU will arrive earlier than expected (Christmas comes early this year!). Not too worried about the sheets: *if* there is a demand for them, some third-party *will* eventually do even glossy-starry graphene-garolite-substrated sheets…

Most excited (and surprised) about Prusament. Will definitely check, either via Amazon or the voucher. Got a couple of questions, though.

First: Will you release the CIELAB data for the colors? With them, you get a pretty good idea and can even approximate RAL… That “heraldic” Azure looks a lot like Sky Blue, but not sure about Lipstick: is it fiery like Traffic Red, or something more subtle like Pearl Ruby? (And don’t get me started about grey windows…)

Second: Are you planning or thinking about no-spool refills (i.e., RichRap’s MasterSpool)? They’re not only eco-friendlier, they’re storage friendly also. My “vacuum” bags can bend a half-used spool pretty badly, but they work beautifully with filament rolls…

So, kudos to all the Prusa team.

3.4.0 to 3.1.1

Debido a eventos inesperados en la versión 3.4.0 necesité devolverme a 3.3.1 en mi MK3.

Eventos:

1. Durante el proceso de impresión de cualquier objeto me pide cambio de filamento sin haberlo programado de esa manera. En un objeto me llegó a pedir hasta tres veces cambio de filamento. Se presenta en TODOS los modelos que imprimí.

2. En el momento de cambio de filamento por uno de otro color y luego de introducirlo, me pide la opción de silenciar o no la alarma(??) para luego continuar con la impresión.

3. Cuando estoy retornando al menú principal no es claro el mensaje de la primera opción en el menú siguiente.

La versión 3.4.0 que descargué es en idioma español.

Por favor corrijan estos problemas, deseo tener en mi MK3 la última versión CONFIABLE.

Gracias

Have you published a guide for M42?