I have been teasing this for quite some time, and it is finally here! We have custom flavour of Slic3r. Slic3r Prusa Edition, which is perfectly tweaked for the MK2. The main reason for our push for developing the Slic3r further is, to remove the need to fiddle with many slicing engines to get great prints. Many veteran MK2 operators now even comment that they would not buy Simplify3D again after playing with the updated version for few weeks. This motivates us to go even faster.

As Vojta mentions in initial Github commit we decided to push the Slic3r development forward at a higher pace, meaning that our Slic3r Prusa Edition now contains features, which are not yet implemented in the official Slic3r.

The main improvements we did in this big release:

- Infill

- Surface

- Supports

- User interface

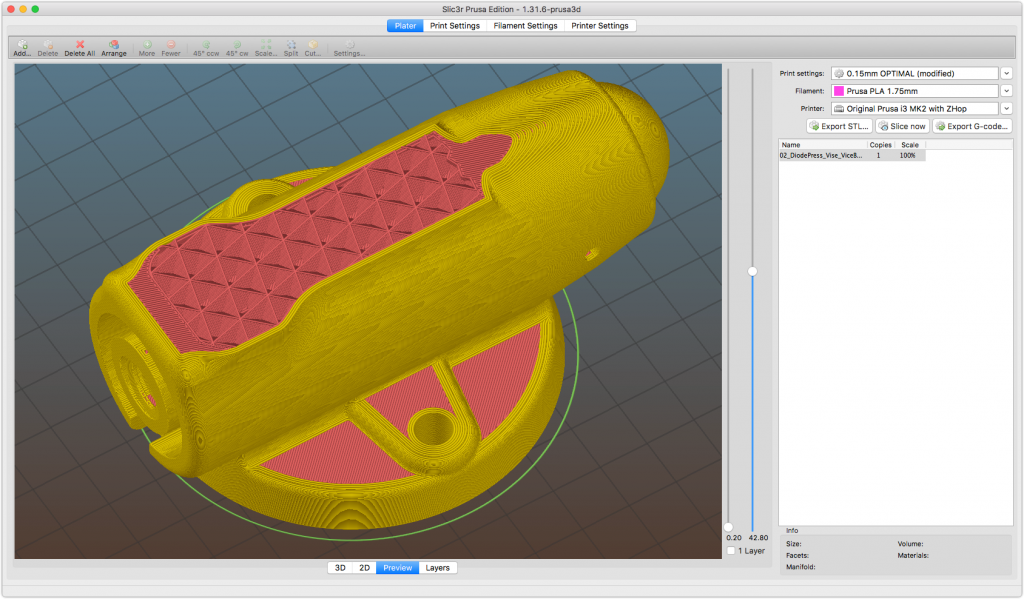

Cubic infill

We added a new default infill option – Cubic. This infill type is special because it makes object strong in all directions. Compared to old style infills were you could compress the object in horizontal plane, similarly like accordion. Only top and bottom solid infill prevented this, but Cubic infill make the object rigid by itself! This is perfect for mechanical parts, less print time and material is needed to get same if not better structural results!

There are many more changes under the hood, including complete rewrite of infill into C++11, which is great for future speeding things up.

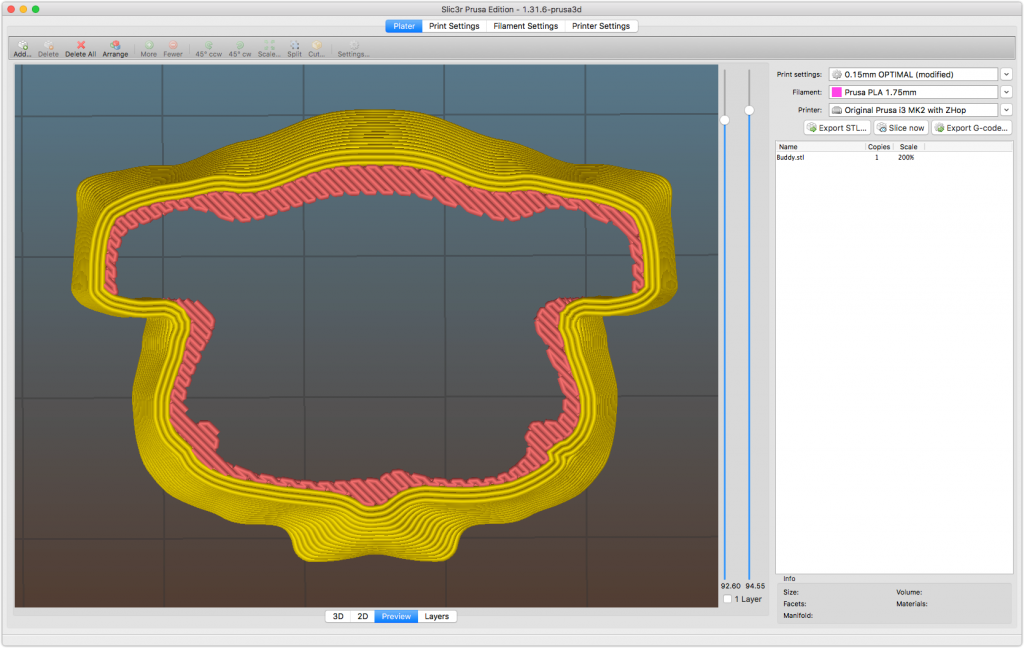

Surface

New magical option appears in the the new Prusa Edition Slic3r, and that is “Ensure wall thickness”. It solves one of the biggest issues of original Slic3r, and that is having holes between the perimeters on a slanted surface. This was typical when printing busts and other organic looking models. Object printed great but on top of the head there were few ugly holes, what a bummer :-/ Well, not anymore. Slic3r now makes sure it lays down the needed supports for perimeters in upcoming layer as seen in red on the picture below.

The results are incredible as you can see on the pumpkins below. On the left is the original Slic3r and Prusa Edition is on the right. It is really night and day difference!

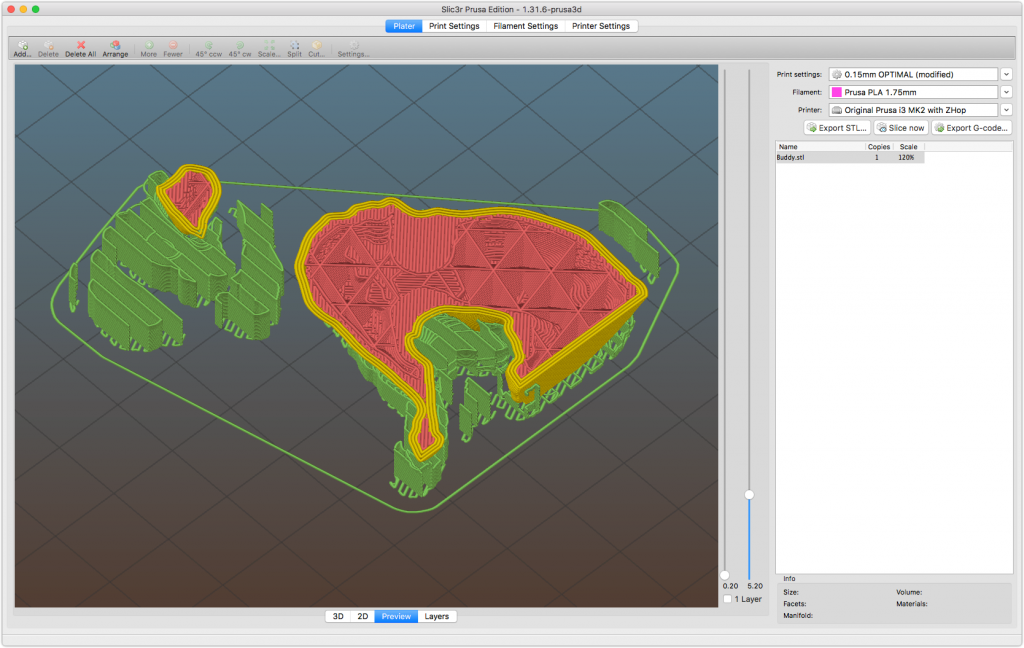

Supports

Supports are always a question when it comes to FDM printing. Slic3r wasn’t the best to say at least. But with our tweaks we are getting there, right now I would personally say we are at roughly 90% of the Simplify3D success rate and work great! They are still bit slow, as they are still not ported to C++ but they are the main priority now! Ability to work efficiently with soluble supports is being baking in as we speak, because the multi material upgrade is coming out soon 🙂

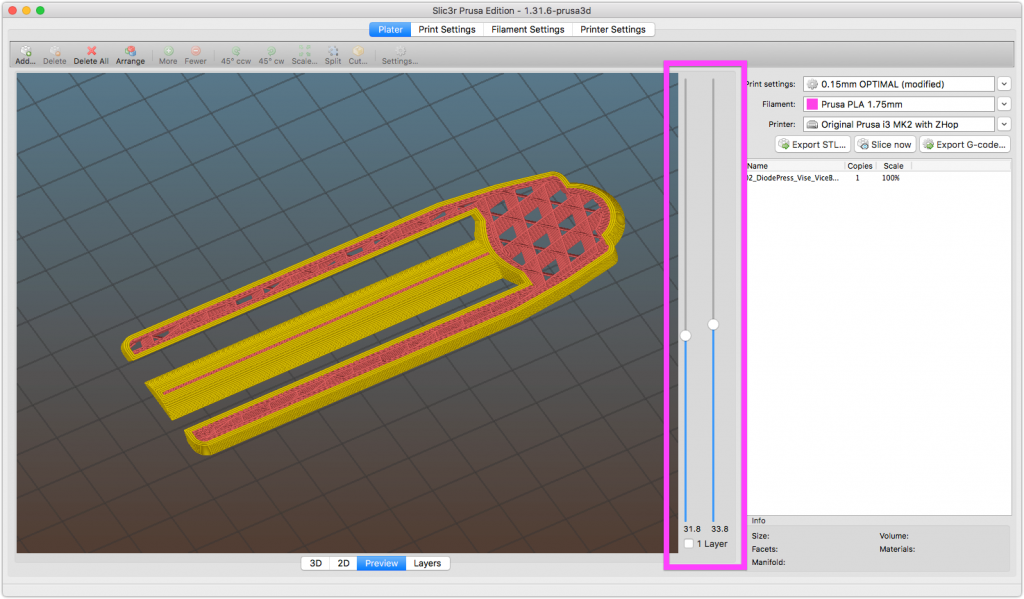

User interface

Added slider (marked in pink) in g-code preview window allows you to see only section of the sliced object without the distracting details. There is even an option to show only 1 layer which locks both sliders together and showing only selected layer.

Another great addition is a “Slice now” button, which generates the model without saving it. Background processing will be turned off from now on as it makes the Slic3r user interface very laggy.

The future

The future plans are simple, we think Slic3r Prusa Edition is pretty much future complete now and most of the work now is optimizing everything. Everything is being rewritten into C++ and parallelization is being introduced to get more out of the modern computers. If you wish to help us out with bug reports, feature request and so on, best way is to visit our Github page https://github.com/prusa3d/Slic3r/

More info, builds and full changelogs are always available in releases https://github.com/prusa3d/Slic3r/releases

Slic3r Prusa Edition is included in Prusa3D Drivers package 1.7.5 together with updated settings for Original Prusa i3 MK2. Go check it out, we added new “0.15mm OPTIMAL” print settings. It has the best ratio of speed and quality and I must say, that 150um suits MK2 the best. I cannot wait to see your shiny new prints!

Happy printing!!

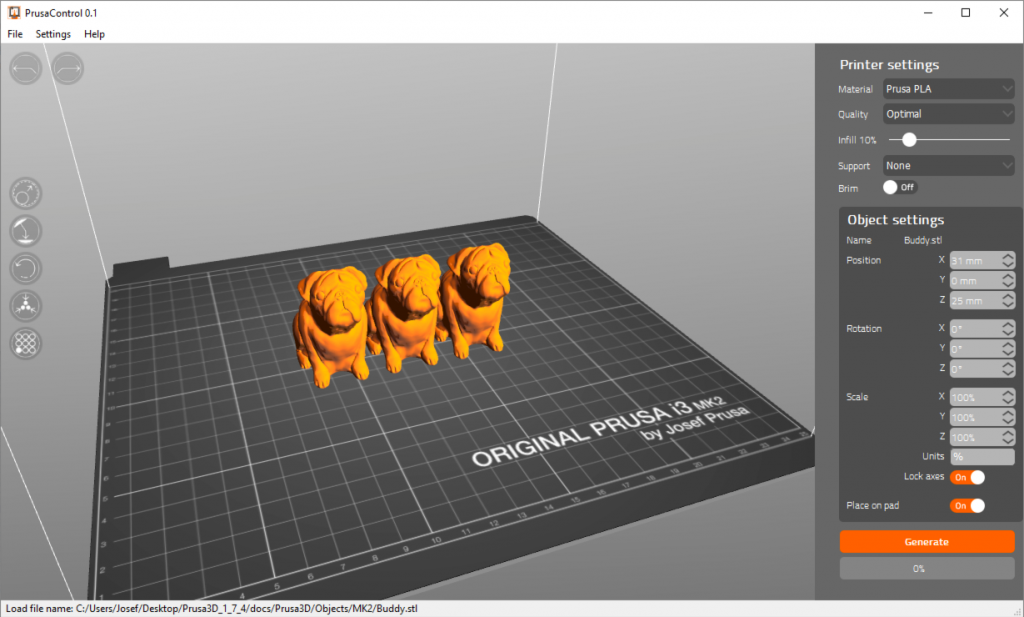

PrusaControl tease

PrusaControl is being developed in parallel with Slic3r Prusa Edition and eventually will become the main user interface. This is a little tease from the newly skinned version. We are hoping to have beta release for Christmas

Good to see continued development on this. One of my main reasons for switching to SImplify3d from slic3r was the ability to add custom supports. Can this feature be added?

I have tried the new version and I am either doing something wrong or there is a new “feature”. I can’t seem to move the object out of the center of the build area. I have had a couple of builds that I did that where one of the objects features landed on a screw that holds the bed. I think that this caused that piece of the object to not stick. In this case it was a support for an articulated head on an papa noel figure. When I move the whole object away from the screw everything worked fine. Besides that it would be nice to be able to reposition an object if you want to make several.

I haven’t tried the cubic infill but it sounds like a good idea. I had wondered if it was possible to set an offset into each infill layer so that they don’t all line up. It would allow a sort of crosshatch that would give the whole model more strength.

Love the printer. Keep up the good work. I plan to order your multi-filament upgrade in the new year.

Go to “Preferences” and uncheck “Auto-Center Parts”

A bug that comes from the original Repetier is that when you change a file that is loaded, say edit it and resave it, Repetier asks if you want to update. if you say yes, the program loses focus and you end up where you were before, like the editor that you used to change it. You need to select repetier to get back. the file is updated. Just an annoyance that has been there forever!