2019 is finally behind us and what a year it was! We launched three printer upgrades, two new printers, a new community hub, broke a world record… simply put: we were super busy and we could finally take a few days of rest. But we’re back on track now, so here’s a quick recap of what’s going on!

So many boxes!

Let’s take a look at some numbers first – because they are, frankly speaking, amazing: in 2019, we sold over 60.000 Original Prusa MK3S and 8.000 MINIs, 180.000 spools of Prusament. Yes, you read that right: 180k! Stack them all up and the tower would be over 12 km tall 🙂 We are still working hard to ship your orders even faster and to get rid of backorders. It wouldn’t be possible without the effort of many, many people – this is also why our team expanded from 320 members to 450! Four years ago, there were just 30 of us… it’s both crazy and awesome to think about it!

Of course, all the departments grew in size, not just the warehouse or manufacturing teams. Our software and hardware developers were pretty busy the whole year as well! We started shipping updated 3D printers – MK3S and MK2.5S (along with upgrades to existing printers), plus our very first SLA machine, the Original Prusa SL1 along with the Curing and Washing Machine (CW1). We also released the updated Multi Material Upgrade 2S, because we received a tremendous amount of feedback on the MMU2, thus MMU2S was born – improved and more reliable.

My favourite multi colour print to date 😍 The orc by @wekster2507 printed at 0.2mm layers 609% scale on my @Prusa3D #MK3S & MMU2S over 96 hours none stop printing & nearly 2000 tool changes in silk PLA from @halo3dfilaments purge to infill turned on & I also had a purge object! pic.twitter.com/N5mZfqKK5w

— Tom Jackson (@FilamentFrenzy) January 10, 2020

However, in case you are experiencing trouble with your unit, check out our recently published guide that deals with common assembly issues. And we also released two new MMU2S videos with useful tips and tricks. Check them out below:

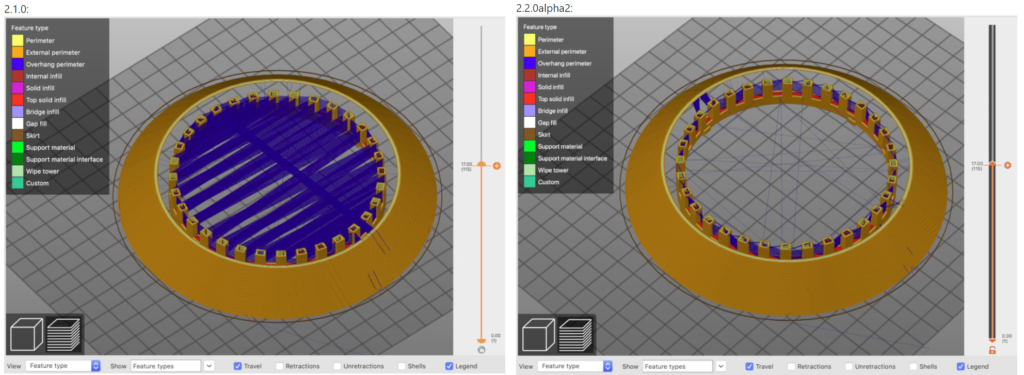

In 2019, we’ve also launched our redesigned community hub PrusaPrinters.org with unique community features and a large model database that keeps growing every day. And our slicer team implemented so many new things and changes into our slicing app, that we decided to redesign it and rename it completely – have you already tried our new PrusaSlicer 2.1? It has a ton of useful features (and yes – even undo/redo now!) and a new version will be released soon.

PrusaSlicer 2.2 will bring hollowing for SLA models, which will help you save precious resin and automatic layer height editing. Plus, there are some improvements for model fixing, new filament manager and more! You can try the alpha2 version of PrusaSlicer 2.2 by yourself, just download it from our Github page. I am extremely happy what our slicer team, with Vojtech as the lead, was able to do in 2019. Now, we’re adding the last (and often somewhat rare) features that you might have been missing when you compared PrusaSlicer to other slicers. So if you’re not using PrusaSlicer, because it’s missing one or two special features, chances are they will be added very soon. I truly believe that by the end of 2020, PrusaSlicer will be the most used slicer out there! Our content team also created extensive documentation which will be live in the next few weeks, but that is just a cherry on the top.

Original Prusa MINI after one month

The Original Prusa MINI was one of our most successful launches ever. We set ourselves the goal to ship the first day orders in December and it was crazy. You see, there was a catch – we expected MK3S sales to go down, but they didn’t (more on that later). Everybody was working day and night so we could ship as many orders as possible – before the winter holidays, of course. We will be expanding our team this year to accommodate the additional load on our manufacturing.

The first wave of feedback on the MINI is very positive and I’m glad people are starting to realize that the machine is much sturdier than it may look. There are already dozens of photos of beautiful prints on Facebook, Twitter, and Instagram, so if you want to check out how the MINI performs, go right ahead.

The Mask by @wekster2507 is done and It’s stunning, model detail and character is CRAZY!

Printed at 150% scale on the @Prusa3D mini at 0.15mm layer heights with a 0.4mm nozzle using #PrusaSlicer in @prusament pearl mouse PLA!

It really is time to P A R T Y! pic.twitter.com/hMAgw6PgeT

— Tom Jackson (@FilamentFrenzy) December 24, 2019

Even after two months of internal and one-month external BETA testing, the MINI still has some teething problems as every new product. We already know what they are and how to fix them. So let me address them here:

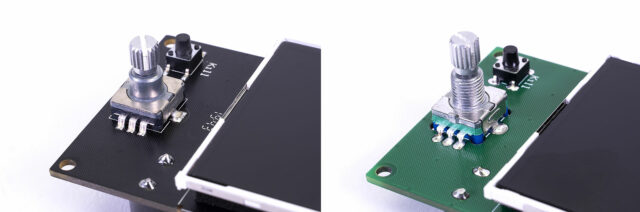

Rotary encoders on the LCD panel are the first on the list. We register a slightly larger than average fail rate of this component: after a few days of use, the rotary encoder (the “knob”) just gets stuck. Unfortunately, the encoder selected by LDO Motors proved to be the culprit of the entire issue. So now we’re working with the supplier to fix the situation. The problematic part will be replaced with an entirely new one – it’s going to be the same encoder we use on the MK3/S. A new, fixed batch is already on the way.

Old encoder (left), new encoder from MK3 (right) – please note that this is a module for internal testing, your module may look slightly different

A stuck encoder prevents you from using the printer properly so it’s more than an annoying bug. This is why we will ship only the updated version from now on. We’re not expecting massive delays, the production still runs, as usual, the printers will just be shipped once we have the new parts. We estimate that we should resume shipping early next week. We test every part of the printer, and the rotary encoder is no exception. There’s even our custom-made machine for testing the encoders – see the video below. However, we did not expect the kind of scenario I just described.

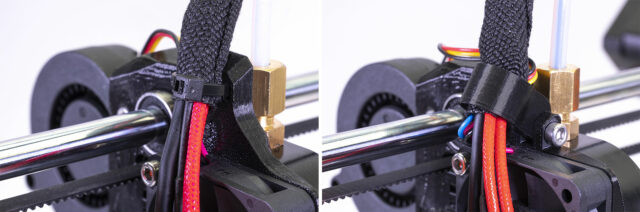

The second known issue is that the MINDA mesh bed leveling sensor may arrive either misaligned or with a damaged cable – this is caused by the zip tie securing it to the X carriage. This kind of damage is usually caused by shipping, e.g. when the box has to survive some very rough handling. We modified the MINDA mount and prepared a new 3D printed part which should make this kind of shipping damage much less frequent (or even non-existent, hopefully). We also received several complaints stating that the electronics box was cracked. Again, this was caused by improper handling of the shipping box. Rest assured, the packaging was properly tested for potential weak spots, however, it seems that sometimes the boxes get some really bad treatment, which is something we can’t control. We have improved the electronics case and made it much sturdier, so it has better chances of survival. So, of course, do not hesitate to contact our support if you experienced any of these issues!

Old MINDA mount (left), new improved sturdier mount (right)

Old cable mount with a zip-tie (left), new improved cable mount (right)

Also, some users expressed their concerns that the cables leading to the print head might be too tight – the upcoming fix takes that into account as well. And one more thing that doesn’t directly affect the printing, but we’ll be addressing it as well as there is the possibility that the MINI can scratch your table – this is caused by the screws on the bottom and we’re focusing on it as well. If you need an immediate solution, you can move the rubber foot on the bottom of the electronics box closer to the middle, so the nuts are not resting on the desk.

So all of these issues will be fixed in the upcoming days and as the current owners have already confirmed, the machine can produce some really amazing prints. Plus, you can expect new firmware updates coming soon – one of the upcoming features is a web-based printer control system called PrusaConnect. Check out the previous article about the MINI to see the WIP version. We’re working on a lot of cool stuff, and if you have any specific wishes or ideas, let us know in the comments!

MK3S still going strong!

As I already wrote, MINI was one of our most successful launches ever and while we are incredibly happy with its sales, there’s one thing that caught us by surprise. We expected MK3S sales to go down after the launch of MINI, but… It didn’t happen at all. In fact, it was the exact opposite, so this is the reason why the lead times are back. However, you do not need to worry – we can now predict the volumes and we can safely scale up.

One side note: we really cannot scale up only for the expected peaks, which is something several of our community members suggested to do. It happens just one or two times a year and it could be very risky. I am pretty sure everyone heard the recent stories of printer manufacturers going out of business.

So while the MINI is performing wonderfully and we’re also working on the new “Prusa XL” 3D printer, the MKx series is still our top priority. You can expect multiple new firmware releases this year with the 3.9.0 version literally around the corner. The majority of work on the 3.9.0 has been carried out before Christmas and we’re testing the latest build now. What can you expect? A lot! We managed to squeeze in quite a lot of new features, mainly thanks to our community members – a huge thanks to everyone involved, namely: leptun, wavexx and 3d-gussner! You can take it as a little teaser for our upcoming community development program. We’re bringing you things like Linear Advance 1.5, first layer calibration for nozzles of different diameters and also a maintenance pause (which allows for better access to the nozzle in case you want to clean it). Plus several enhancements and bugfixes. We wanted to implement backward compatibility for Linear Advance 1.5, so even older G-codes would work and that’s why it took so long.

Around the world in 365 days

Meeting makers and 3D printing enthusiasts all over the world is one of the things about this job that I love the most. In 2019, we’ve visited 38 events and we’re going to travel a lot in 2020 as well. Meeting new people, learning about their projects, sharing the passion for 3D printing – it’s amazing! If you haven’t been to any of these events, check out our videos on our YouTube channel. Maybe you’ll change your mind 😉

And also let us know in the comments, where we should head out to next! We can’t be everywhere, but we love to visit new places! You can always find the current list of events we plan to visit during the upcoming months on our website.

Join PrusaPrinters!

Speaking of community and meeting new people: you can, of course, become a part of our community at least in the virtual world. Our community hub PrusaPrinters.org keeps growing every day. The model database is growing tremendously and it will soon surpass 10.000 models! One of the great things is that the quality of uploaded models is usually very high and there’s a minimum of useless things, so even though the number is lower compared to some of the long-running websites, our users are uploading a lot of quality stuff!

This is also possible due to our nifty Thingiverse importer – with just a few clicks, you can validate the ownership of your Thingiverse account and copy your projects to PrusaPrinters, increasing the reach of your projects. It is also a great way to backup your Thingiverse models, in case they will pull the plug on this service :-/

We started organizing cool contests and also expanded the user base beyond Prusa owners – if you have a different 3D printer brand, no worries! You’ll find plenty of great stuff here, too! Wonder what’s next? Translations, event management and much more… we’re listening to your feedback so most of the changes are made based on the results of our recent survey.

150.000+ printers in the wild!

MK3S, MK2.5S, SL1, MINI… our lineup is stronger than ever, which allowed us to conquer an incredible milestone: over 150.000 of our 3D printers have been sold during the existence of Prusa Research.

How Czech startup Prusa Research hit 17,122% revenue growth, by @KitGillet for @Siftedeu featuring @Prusa3D @josefprusa @toms3dp @makersmuse @joeltelling@3dmakernoob @toms3dp https://t.co/BAh1osavax

— Michael Stothard (@MStothard) January 8, 2020

We gained more than 10% market share – and we celebrated the occasion of 100.000 3D printers sold with a video that maps the entire history of Prusa Research. If you haven’t seen it yet, check it out now – it was a wild ride! And if one “100k” milestone wasn’t enough, we also went over 100.000 subscribers on YouTube! Thank you, everyone! Hope you are enjoying our work! 🙂

Oh, and let’s not forget that 2019 was the year when we finally tackled the issue with powder-coated sheets 😉 If you already have two different sheets, don’t forget to upgrade your printer’s firmware, because starting with version 3.8.0 (the current one is 3.8.1) there are now steel sheet profiles allowing you to switch sheets with greater ease.

2020 is here!

Looking back, it’s amazing how many things happened in the past 12 months! Thank you for being with us on this journey, thank you for your support, your ideas and general feedback. I believe that this community is stronger than ever and together we can achieve something amazing – one such example can be the soon-to-be-released 3.9.0 firmware for the MK3S, which was developed in cooperation with our community members!

2020 is going to be another busy year for us because it’s not just the eagerly awaited “Prusa XL” – there’s more stuff coming. Stay tuned for more announcements! 😉

The entire Prusa Research team wishes you a great and successful year. And as always: happy printing!

I am very pleased to receive some news on the mini. I am glad that the issues are being addressed and fixed. I have been waiting for my Mini since October 13th and am glad to know that its still on its way!!!

Thank you so much for the update!! Its very much appreciated.

Greg

Great article. Glad to see some of the issues I’ve noticed with my Mini are being addressed (I printed gregsaun’s improved parts myself preemptively). I get that you guys want to make it clear the encoder issue wasn’t due to lack of QC, but you didn’t really need to throw LDO under the bus like that… every product I’ve gotten from them has been of expected quality. It’s fine that there was an issue, but just accept that we can understand that and don’t try to pass blame. (It makes you look bad). Excited for Prusa Slicer 2.2 and being able to recommend the Mini to schools though! Keep up the great dev and please try to be as transparent as possible. I’ve decided I have to wait an additional 2 months before recommending the Mini due to the tab not being announced, and I’d really like to see those kinds of information being announced with the expectation that the community will understand why. Announcing them after pre-orders was just wrong.

Any chance I can get one of those upgraded LCD boards?

Same here, and that geared extruder looks awesome as well. Hopefully there are plans to push those upgrades to the MK3S squared!

Do you guys email this info out to people with backorders pending? It would be nice to get an update with out having to search it up- and it might reduce the load on your customer service people

Honestly you have done as much for the competition as you have for yourselves. I still await my mini and due to the delay I have had to modify my Tevo Michealagelo to have a heated bed – mesh levelling and a colour display with networking so it can be properly productive.

It is now supporting my MK2.5 S. I have learnt a lot by this conversion and Im now confident about extending the height of the MK2.5s as well and messing about with Marlin. Will I need to buy another ? Ive seen what CHEP is achieving with much cheaper options. My wish is that Prusa sets more realistic expectation levels on delivery. It will not take too much for a competitor to produce something every bit as good as Prusa and if they deliver on time and give even better support there is room in the market. I wish Prusa well I really like the products but asking folks to wait 3 months or so …… not good enough at any price. With such volumes is it really time to move to moulded and machined parts. Is the print farm dead? So Mr.Prusa climb to 10000 feet and look down on your business – its very fragile – all businesses are. For 3D printing Im a hobyist/ small producer. In my main business life I look at things differently. Good luck its great to see such success. P.s I just bought a E3D Hemera – a masterpiece! Please consider these in your equipment.

I don’t agree that Prusa should move aggressively toward printed & machined parts. That kind of move takes a big cash commitment, lots of time, & locks you into a specific design path that is not easily changed. Just look at what happened to Lulzbot. By comparison, an FDM print farm is nimble, & at $350US per increment of capacity (the Mini) – very scalable. Josef & the team understand their business very well & are doing the right things to benefit their customers. The delays with the Mini are minimal & are to be expected with a business growing this rapidly – both in number of units & expansion of models & services. Keep up the good work!

Great article Jo! It was my best year in 3D printing for sure. It was great to meet you for the first time and I’m so proud to be part of your beta testers team!

2020 will be another great year, I’m sure about that. I can’t wait for the XL to be released and see all the other things you guys will release this year.

Hope to see you again soon!

Any idea if you can tell us where you are on shipping atm? since all we know is you have shipped Some..

Thanks for the update on the Mini. It seems to answer most of the questions and concerns I had. I ordered mine on the 14th, so it looks like I avoided some of the teething issues of the first batch. I’m looking forward to printing with it, and it looks like the Mini will be a good printer to recommend when friends and family ask. The Mini also looks like a super good choice for schools.

All very exciting stuff and really curious to see how this Prusa XL will turn out. My main question is whether or not the Ms. Pink filament is discontinued as it has been many months since it was last available. In a previous blog post they announced they would re-stock all filament and Ms. Pink never became available.

Anyway, love all the other filaments and plenty to keep me occupied in the meantime!

Amazing progress and an amazing company. It’s difficult to successfully grow a business so fast and remain stable.

I took advantage of your Thingiverse import feature in late November 2019 (Startrekfan2). Thingiverse was a wonderful platform at one time, but has lacked the maintenance that it deserves. This week I received a message from Cults 3D that they have a similar import feature.

I am very happy with my i3 MK3 purchased in May 2018, and I look forward to your XL version later this year.

Prusa XL is like MK4 or completly new design? It will be like Zaribo 420 or CoreXY? I can’t wait that! If MK4 will be like MK3, please remove Z frame and mount aluminium profile.

Please add fuzzy in Slic3r and ironing! Fix line visible on benchy and all models with walls.

Too much wishes ☺

My wish for the mini firmware is an option to save and use the z offset for booth sheets (PEI and powdered) … additional in the slicer the option to tell the mini via gcode on which sheet I gonna print.

Happy New year dear Josef & team.

Last year in autumn I bought my MK3S as a kit which I assembled during a live stream. 3D-Gussner was so kind to be virtually by my side.

I’m so happy with the printer. I really wish that I would have bought it earlier.

Kind regards from Katja aka Cat3D

Thank you for the continuous effort to improve your printers, software and other elements necessary for 3d printing.

I started buying an MK2s printer and from upgrades I turned it into a MK2.5, MK3 and, finally, a MK3s.

This has given me insight on the improvements that the different versions have brought to the final product. Regarding the quality of the prints I can confirm that they have not improved at all. The initial quality is as good as the current one. This is not a criticism at all, instead, it can be a compliment to the quality of the MK2s.

Of course, the improvements have facilitated the set-up, speed of configuration and convenience in printing. What is not little. 3D printing is now much more pleasant than before.

I suspect that FDM printing, with respect to the final printed product, has little room for improvement. That has made me look at the SLA (or SLD) printers. But he has never convinced me at all.

Is it possible for the future MK4 to change this situation? Or will it be a further improvement in the process of printing and configuring the task?

Again, thank you for your work and dedication and have a great year 2020.

Honestly, the networking features I would look the most forward to in the MINI arn’t even ones on a web interface.

What I would like most is a one-click print button from within PrusaSlicer that uploads the G-code to the mini without having to move SD cards or flash drives around.

A simple REST API that lets you read some basic things like the print time and temperatures would be nice too 😀

Congratulation to your success! I also congratulate myself for making the decision to order a prusa MK3 (now MK3S with powder-coated steel-sheet) at the end of 2018!

After some disappointing starting-troubles with first layer that did not really stick after some weeks everything went fine und 3D printing has become to fix part and improvement in my hobby-show-life.

The robustnes, precision and ease of use of your printer helps to focus on the design work.

Wish you a successful 2020!

Hello Prusa team. I found another problem with the Mini that should be solved. When I print flexible filament and change filament when changing color e.g. because of the flexible filament, he doesn’t pull the filament back far enough for me to get it out of the extruder. But I have no possibility to eject the filament in this menu any further. So I had to open the extruder and pull it out a few centimeters by hand. The solution to the problem is that you can either just pull it back a little further in the software for flexible material, or you can add a function in which you can push the filament out again. Just test it yourself and you will see what I mean.

Hey there. Nice job. I’m pretty happy with my Mk3s2. Do you think that there will be like an upgrade kit from Mk3 to XL? xD

Hello Prusa team, did you start shipping MINIs again? Thanks.

What a lovely blog you have here… I love the details you brought, especially the way you brought them out. Do you mind if i quote a few of your words on my blog? We are in the exact same niche. You can read sabwap on my site. Please reply me or let me know when you make a decision. Once again, Lovely Contents.

I hope for the XL (definitely will buy) you guys might consider a hemera extruder/hot end.

Hi,

thanks for all the info. Let me do a proposal for potential future upgrade kits: https://www.heise.de/make/artikel/Rotoprinter-3D-Drucker-mit-Rotationsachse-4652969.html.

This article is in german, sorry for this, but it describes an interesting new principle for an upgrade. Maybe, you can consider this approach.

Best regards

w

The dxf file is faulty

Having nothing but print issues with Original Mini…No changes with updated firmware or new PrusaSlicer 2.2. Very disappointed.

I can say for sure that such innovations are now very necessary, as well as business solutions, because many businesses still have manual, without automated management and solving complex problems. That is why I recommend to study the salesforce implementation plan and use this knowledge to configure and implement Salesforce in your company’s robot. I think it will be most useful now and there are few places where you can get such knowledge. Good luck.