Prusament is three years old and I’m happy to announce that now it has a younger sibling: Prusament Resin! 🙂 This is our brand new, in-house manufactured, high-quality resin for fast and reliable printing. It’s much more, though. Prusament Resin aims to increase comfort and safety during use – the ingredients are specifically chosen to minimize bad odors and health risks. Of course, mechanical properties are fine-tuned as well, so you can create solid, sturdy 3D prints.

The story behind Prusament Resin is pretty much the same as with Prusament filaments. Once we dug into SLA 3D printing with our SL1, we soon realized that especially the manufacturers of cheaper resins have trouble keeping the quality of their products consistent. For us, this usually means we start researching whether we couldn’t do it better. Fortunately, we have our “secret lab” on the outskirts of Prague (where we also develop our satin print sheets) – and after many months of their hard work, the result is finally here.

And why is it called Prusament Resin and not, for example, Presin? It’s simple: we believe that over the years, Prusament became a very recognizable brand on its own. If you’re looking for the right 3D printing material, Prusament has you covered – no matter whether you need filaments or resins.

Mixing the perfect blend

Our priorities were pretty much clear from the beginning: we wanted to make a high-quality resin that would be easy to print, have the lowest possible odor and health risks. And, of course, the prints will have the highest possible level of detail. Our research gave us the possibility to control and select every ingredient to make a resin with desired properties – our goal was to create a substance that has a minimum of negative effects, especially on health.

Wait, does that mean regular resins may be dangerous for your health? Well, turns out that there are still products on the market that still contain a dangerous component – Bisphenol A. According to published papers, exposure to Bisphenol A may be a concern because of the possible negative health effects on the brain and prostate gland of fetuses, infants and children. It can also affect children’s behavior. Even if these may seem like extreme cases, we simply didn’t want to venture into this territory at all.

The health aspect seemed essential to us since regular tough resins are frequently used for hobby purposes at home. That’s why we tried to avoid chemicals with a strong odor, health risks, high toxicity, and also mixtures containing Bisphenol A. The final product is a resin with a lower odor and health impact, compared to the other products on the market.

We run our own independent development, without cooperation with other manufacturers. This gives us a great advantage in controlling the chemical composition and achieving the desired results. The difference between success and failure often lies in minor changes in the formula. We used various analytic methods, such as measuring mechanical properties, viscosity, hardness, or colorimetry.

We will, of course, continue our development and add new special materials to our portfolio in the future. We’re talking about flexible resins, materials for dental and medical use and other types of materials. Just like with the FDM 3D printers, the MSLA technology also requires the machines and materials to be “in tune.” And since we now internally develop and manufacture SLA 3D printers and resins, both teams can benefit from each other’s research and development.

| Main advantages of Prusament Tough Resin | |

|---|---|

| Print reliability | |

| Short exposure time (1.6-2.4s on the SL1S SPEED) | |

| Great print detail | |

| Good deformation resistance | |

| Low odor | |

| Low health impact | |

| Does not contain Bisphenol A | |

| Disadvantages | |

|---|---|

| Non-recyclable material | |

| The uncured resin might still pose a health risk | |

| Lower temperature resistance (50 °C) | |

Printing with the Original Prusa SL1S SPEED

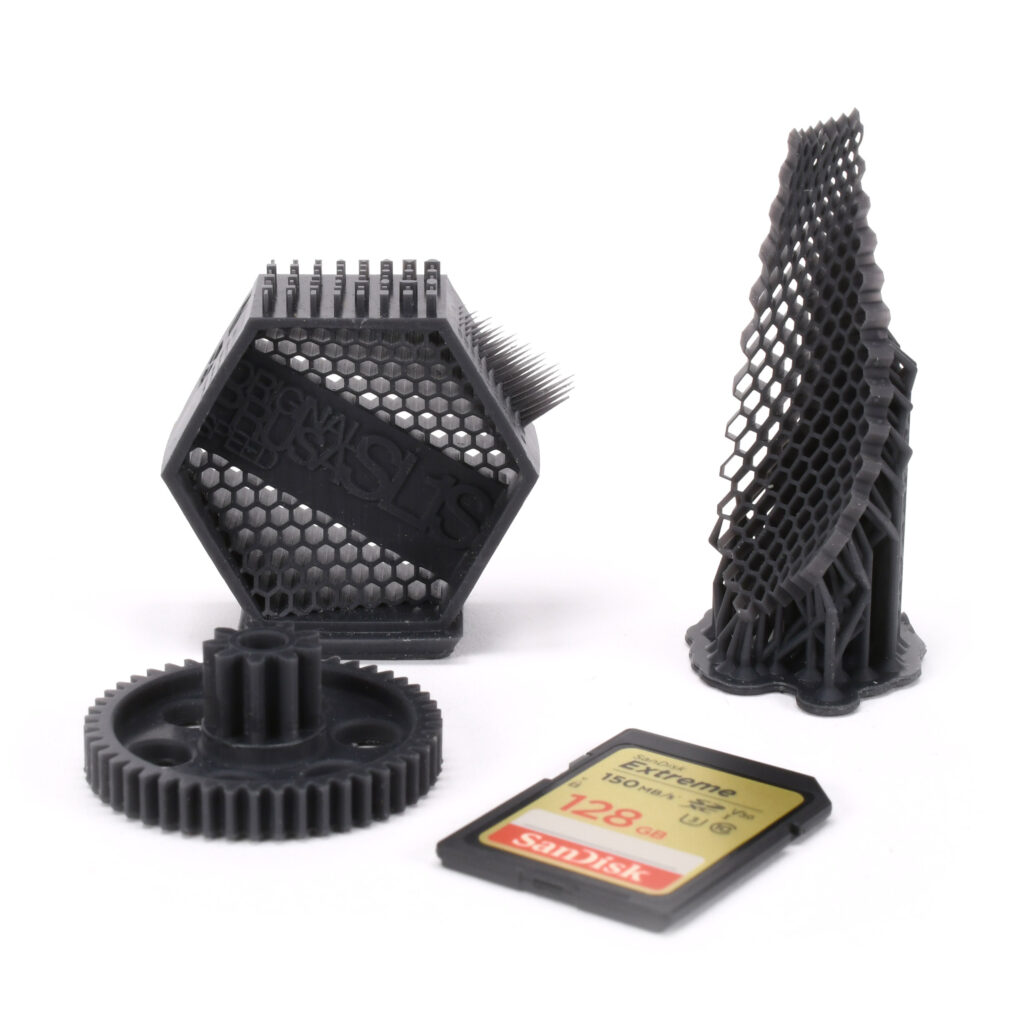

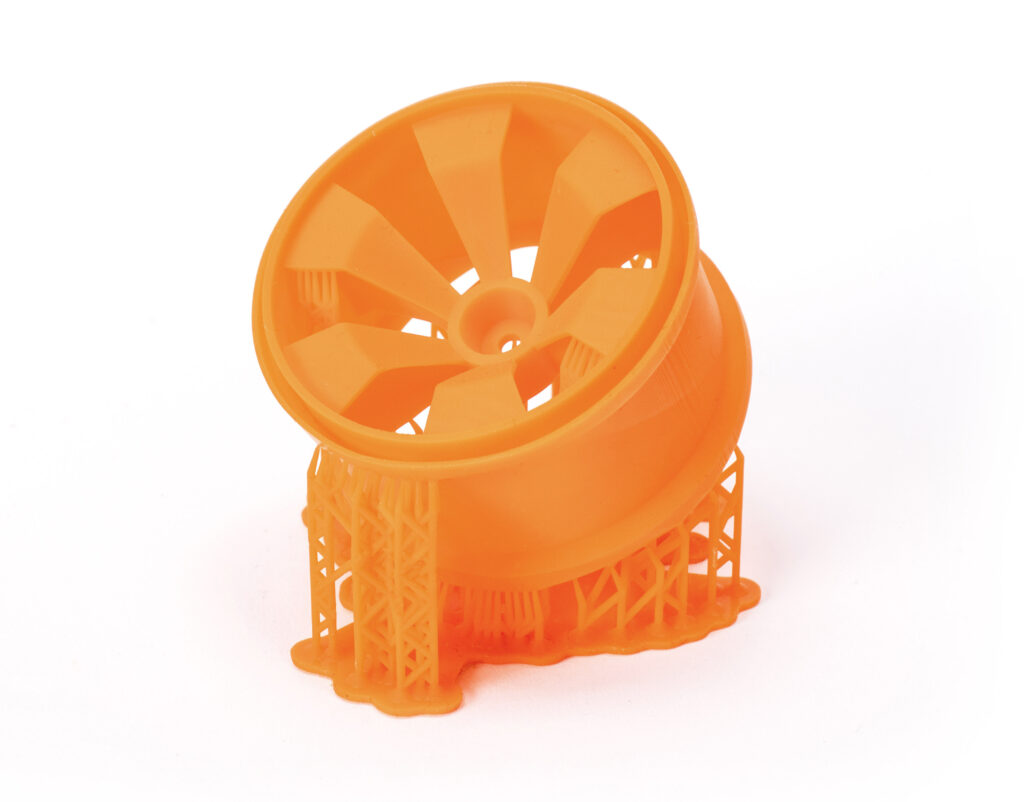

Prusament Resin is perfectly compatible with any third-party MSLA 3D printers compatible with 405nm resins. However, it was tailor-made for the Original Prusa SL1S SPEED. In combination with SL1S, you’ll get amazing speed without losing any print details! Thanks to its monochromatic display and fast tilt mechanism, it’s possible to print with exposure as short as 1.6 – 2.4s per layer, depending on the object size and complexity. Our official and internally-tested PrusaSlicer profiles offer between 1.8 to 2.4 seconds for safer printing. Full specs can be found in the Tech Data Sheet. SL1S SPEED can produce models with the tiniest details fully rendered – and it can do it much faster than other machines, FFF/FDM printers included!

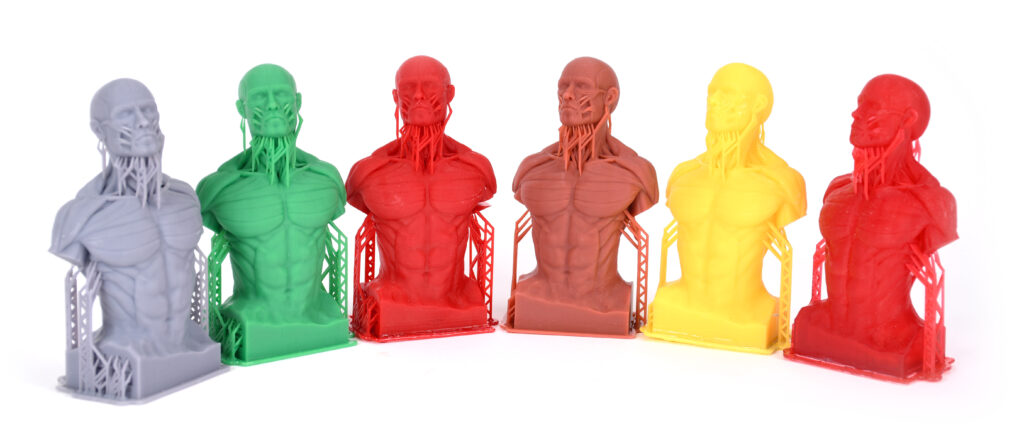

Material type, color, and price

For now, we offer popular tough resins which are especially suitable for printing tiny parts with a high level of detail. These include, for example, plastic model accessories, action figures, jewelry, various prototypes, etc. You can buy the Prusament Tough resin in three colors: Prusa Orange, Rich Black, and Anthracite grey, each of them for 69 EUR (vat incl.) / 69 USD. Right now, we want to focus on the quality, not an infinite amount of variations. But rest assured that more materials will follow soon.

Tracking the origin

Similar to our Prusament (FFF/FDM filament), Prusament Resin will also have its own “birth certificate”. While we cannot offer the same level of extremely detailed statistics, you can still scan the QR code to see the batch number, date of manufacture, and expiration date.

Examples of use

Model & hobby – With Prusament Tough Resin, you can produce objects with excellent details, which makes this material perfect for tiny action models, prototypes, and large project accessories. Material can be easily sanded, both dry and wet.

Rapid prototyping – Short exposure time and the high level of detail make the MSLA technology great for small and detailed prototypes that can’t be made with FFF/FDM printers. Plus, the overall MSLA printing time is shorter than with FFF/FDM.

Casting molds – Prusament Tough Resin can be used for making both simple and more complex molds. You can either print a master model for the mold, or you can print the mold itself, for example for casting silicone.

Education models – Low odor, easy usage, and low health impact make Prusament Tough Resin great for printing detailed educational models.

Art & design – The ability to print very delicate structures makes Prusament Tough Resin a great option for designers and artists. Prusament Tough Resin offers both simplicity and precision.

Safety precautions and manipulation with resin

Before you start using Prusament Tough Resin, don’t forget to read the material safety data sheet (MSDS) uploaded at prusament.com. Here, we sum up only a few tips that might make your life with resin a little easier. 😉

- Always remember that despite all our efforts, all liquid resins still might pose a certain health risk. Use reasonable protection – gloves are a good solution. Prevent contact with skin, eyes, and mouth.

- Accidents may happen even to the most experienced users. If resin gets on your printer, table, or anything else, don’t wait and clean it immediately with paper towels and isopropyl alcohol (IPA), before it gets cured by the daylight.

- Strangely enough, there is not much information available about waste disposal and recycling 3D printed products. Let’s sum up how we deal with resin waste: Uncured resin leftovers should be disposed of with other dangerous chemicals at places designated for it. It cannot be recycled and definitely should not end in general waste. The same rule applies to bottles, paper towels, and models stained with liquid (uncured) resin. However, cured resin (reactoplastic material) is, unlike filaments (thermoplastic material), a non-recyclable material – it belongs in the general waste.

Would you like to know more about the parameters of Prusament Tough Resin? Don’t forget to see our resin section at prusament.com!

We can’t wait to see what amazing prints you’ll make with our new resin!

Happy printing!

I can’t wait to be able to try out this new resin, are there any plans to come out with any more affordable resins from prusament, since this seems to be comparatively on the higher end of prices in resins. If not I completely understand why, this stuff has incredible potential, and I would love to be able to try it out someday when I order it.

I’m afraid not. Tough resins are usually the cheapest and we plan to make more specialized materials in the future.

Thanks for the article, I was looking for this 3d printer ink.

Sounds great, I’m excited to try it.

Any chance of a castable?

When you say “casting silicone” are you referring to tin-cure silicone? Platinum-cure silicone doesn’t like resin photopolymer prints (inhibits the silicone curing)…or did you do something special with your resin?

Any plans for a large resin printer using DLP technology ?